Corrosion and wear resistant coating for magnesium alloy surface and preparation method of corrosion and wear resistant coating

A wear-resistant coating, magnesium alloy technology, applied in the direction of metal material coating process, coating, melt spraying, etc., can solve the problems of low bonding force and limited corrosion resistance, and achieve good corrosion resistance and wear resistance. Low cost and the effect of expanding the practical scope

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

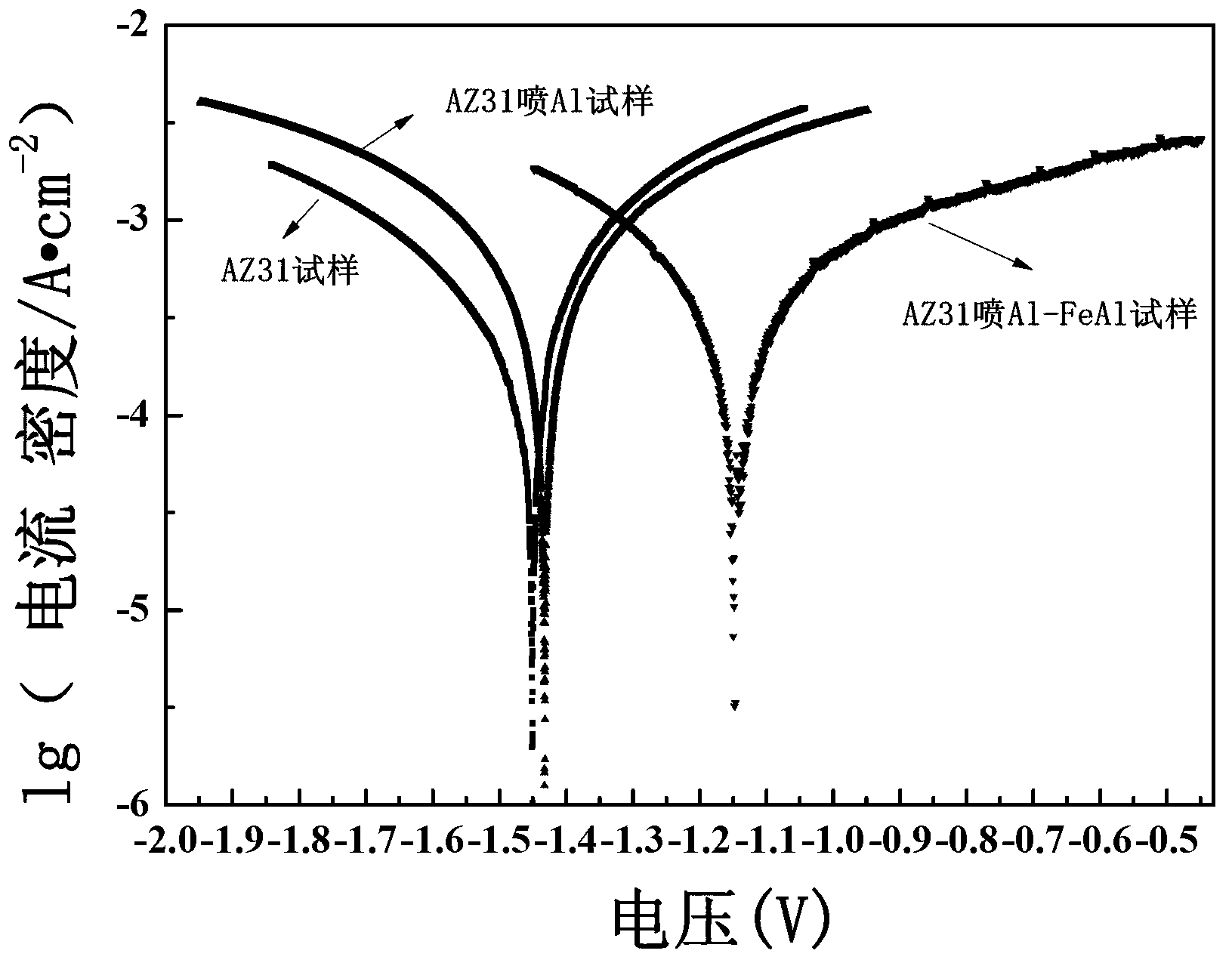

Examples

Embodiment 1

[0022] 1. The Al wire used for spraying is a commercially available solid wire with a diameter of 2.0mm and a purity greater than 99%;

[0023] 2. Preparation of FeAl powder core wire in the embodiment: the outer skin is a low-carbon steel strip with a specification of 12×0.3mm (12mm in width and 0.3mm in thickness), and the core of the wire is Al powder with a purity greater than 99%. , the particle size is 100-200 mesh, drawn and reduced to 2.0mm step by step; the filling rate is 20%.

[0024] 3. Magnesium alloy AZ31 is selected as the substrate, after being cleaned with acetone, sandblasting is carried out, the air pressure is 0.4MPa, and the particle size of brown corundum is 60 mesh;

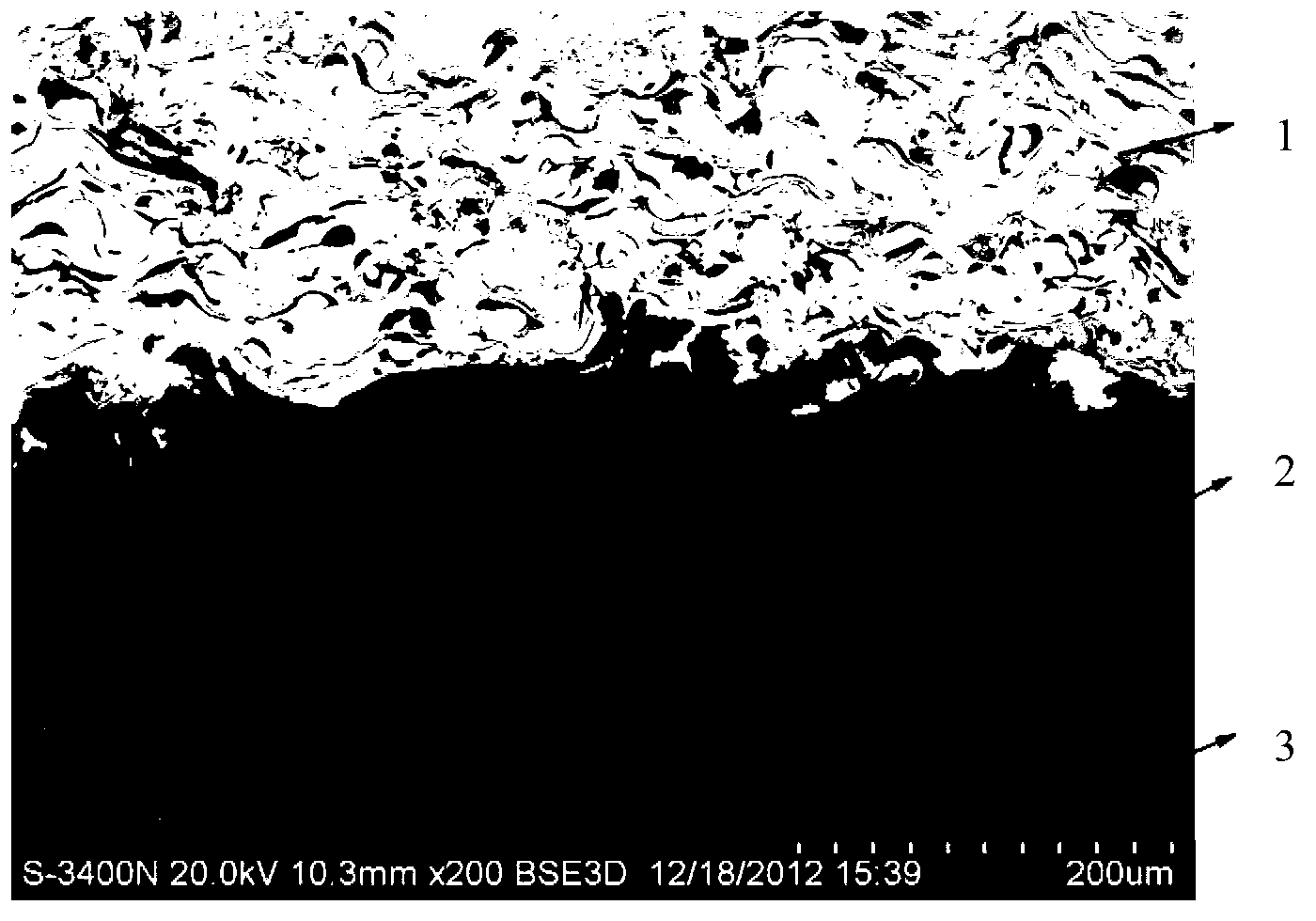

[0025] 4. Arc spray the Al layer on the surface of AZ31, the process parameters are set as: voltage 28V, current 100A, atomization pressure 0.55MPa; each spraying time is 15s, spraying 5 times to get a coating thickness of about 200 microns;

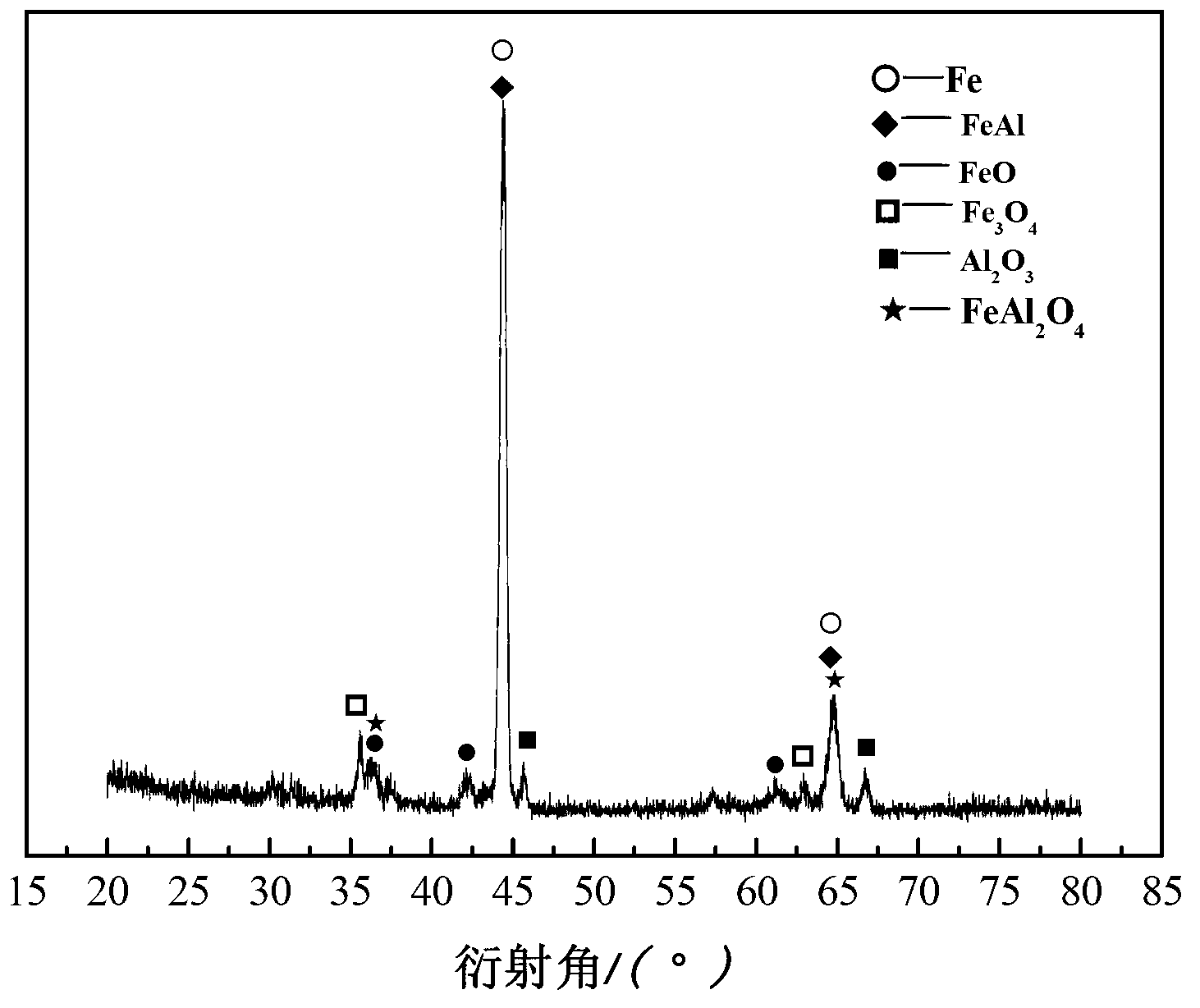

[0026] 5. Arc spray the FeAl layer on the surf...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com