Device for processing microstructure sealing ring part with air plasma shaped electrode

A plasma and forming electrode technology, applied in electrical components, circuits, discharge tubes, etc., can solve the problems of difficult processing of silicon carbide sealing ring parts, and achieve the effects of good processing quality consistency, high precision and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

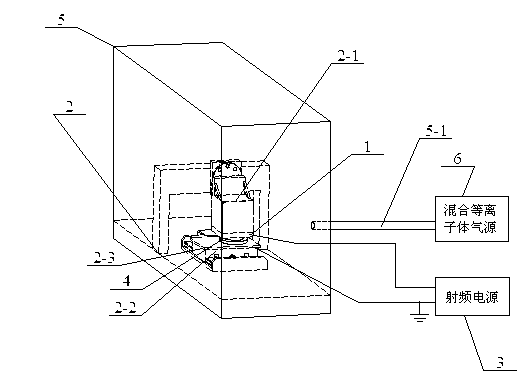

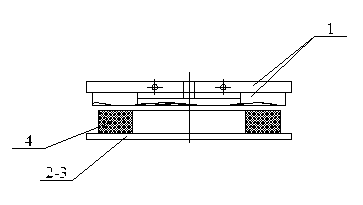

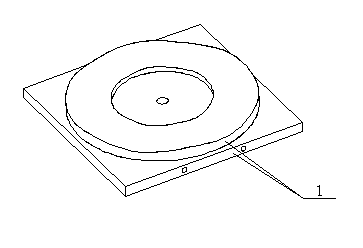

[0019] Specific implementation mode one: combine figure 1 , figure 2 , image 3 As shown, it consists of plasma forming electrode 1, five-axis linkage machine tool 2, radio frequency power supply 3, airtight working cabin 5, and mixed plasma gas source 6:

[0020] The upper end surface of the plasma forming electrode 1 is insulated and connected to the vertical motion working shaft 2-1 of the five-axis linkage machine tool 2, so that the plasma forming electrode 1 is connected with the output end of the radio frequency power supply 3 as the anode of the atmospheric plasma discharge; The silicon carbide sealing ring parts 4 to be processed are clamped on the ground electrode 2-3, and the ground electrode is fixed on the working platform 2-2 of the five-axis linkage machine tool 2; the ground electrode 2-3 is grounded as the cathode of the atmospheric plasma discharge ; The five-axis linkage machine tool 2 is arranged in the airtight working cabin 5, so that the air guide hol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com