Model prediction three-level direct torque control method based on state trajectory extrapolation

A technology of direct torque control and model prediction, applied in the direction of AC motor control, control system, estimation/correction of motor parameters, etc. problems, to achieve the effect of reducing switching frequency, improving energy utilization, and fast dynamic response capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

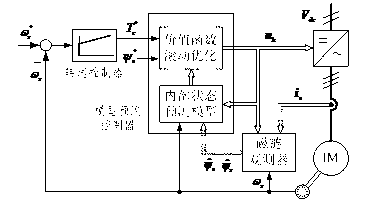

[0029] see figure 1 , the asynchronous motor model prediction three-level direct torque control method based on state trajectory extrapolation, using a model predictive controller to replace the hysteresis controller of the traditional direct torque control; the model predictive controller consists of an internal state prediction model and The value function rolling optimization consists of two modules. The flux linkage of the stator and rotor observed by the flux linkage observer, the rotational speed measured by the speed sensor and the switching vector output in the previous sampling period are used as the input of the internal state prediction model, and the state of the internal state prediction model The output, the given torque and the given stator flux obtained from the output of the speed regulator are used as the input of the value function rolling optimization module.

Embodiment 2

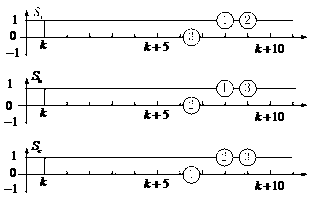

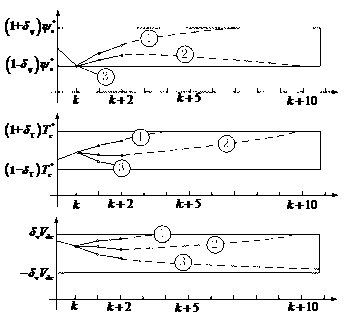

[0031] This embodiment is basically the same as Embodiment 1, and the special feature is: the model prediction controller uses the established internal state prediction model to determine the allowable switching vector according to the switching state of the inverter at the previous moment, and for the allowable switching vector through the internal The state prediction model extrapolates the output trajectory, determines a long prediction range, and then takes the average switching frequency of the inverter as the value function, and uses the limited time-domain rolling optimization strategy of model predictive control to solve the optimal switching vector in real time;

[0032] The allowable switch vector determines the allowable switch jump of the inverter according to the switch state of the last sampling period of the inverter, and the allowable switch jump is clearly defined as the continuity of the jump must be maintained, that is: , and there is at most one phase jump ...

Embodiment 3

[0043] The basic technical framework of this embodiment is: a model predictive controller is used to replace the traditional DTC hysteresis controller. The internal state prediction model is established by the NPC three-level inverter driving asynchronous motor mathematical model and the quadratic extrapolation method, and the allowable switching vector is determined according to the switching state of the inverter at the last sampling time. For the allowable switching vector, according to the internal state prediction The model extrapolates the output trajectory, thereby determining a long prediction horizon. Then take the average switching frequency of the inverter as the value function, use the finite time-domain rolling optimization strategy of model predictive control, and solve the optimal switching vector acting on the inverter in real time. The basic principle framework of its implementation is as follows: figure 1 shown.

[0044] Specific embodiments of the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com