Full-automatic straw harvesting ensiling machine

A technology for harvesting silage machines and rice harvesters, which is applied in the fields of harvesters, animal feed, agricultural machinery and machinery, etc., can solve problems such as environmental pollution, and achieve the effects of expanding the scale of feeding, enriching the meat market, and increasing agricultural income.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Below in conjunction with accompanying drawing and embodiment describe in detail:

[0065] 1. The structure of the green storage machine

[0066] 1. Overall

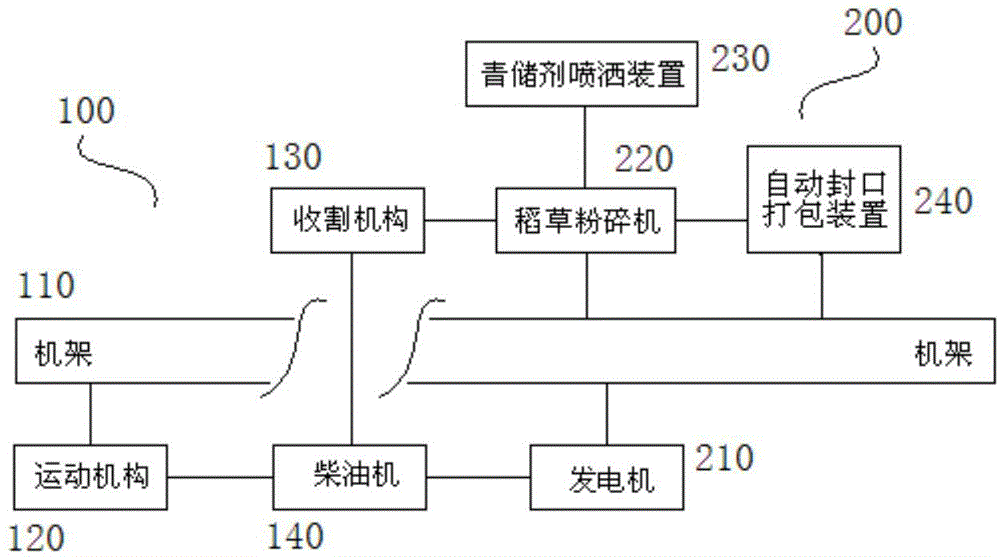

[0067] Such as figure 1 , the green storage machine 200 is added on the basis of the rice harvester 100;

[0068] Paddy harvester 100 is made up of frame 110, motion mechanism 120, harvesting mechanism 130 and diesel engine 140; Frame 110 is the carrier of motion mechanism 120, harvesting mechanism 130 and diesel engine 140;

[0069] The diesel engine 140 is the power of the moving mechanism 120 and the harvesting mechanism 130; the moving mechanism 120 drives the frame 110 to advance and retreat; the harvesting mechanism 130 automatically harvests and separates the straw;

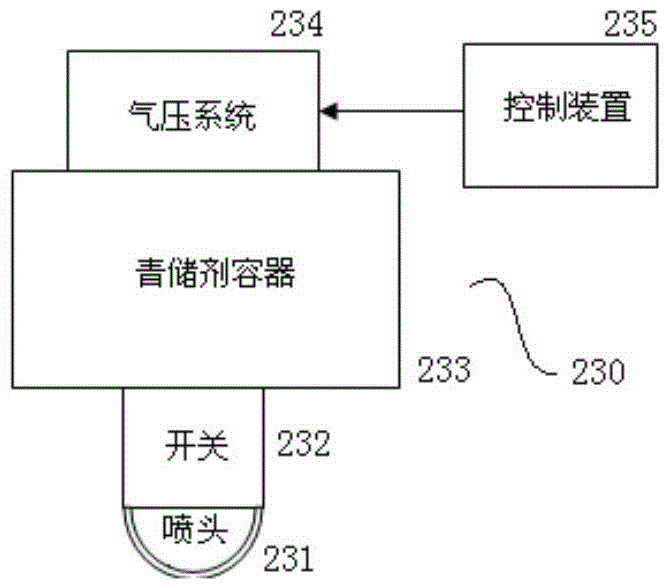

[0070] The green storage machine 200 that is connected behind the frame 110 includes a generator 210, a straw pulverizer 220, a green storage agent spraying device 230 and an automatic sealing packing device 240;

[0071] The outlet of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com