Visible-light-driven photocatalyst as well as preparation method and applications thereof

A visible light and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, iodine oxygen compounds, etc., can solve the problems of photocatalyst quantum efficiency reduction, photocatalytic activity reduction, etc., to achieve large-scale promotion and application, The preparation method is simple, the conditions are mild and easy to control the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

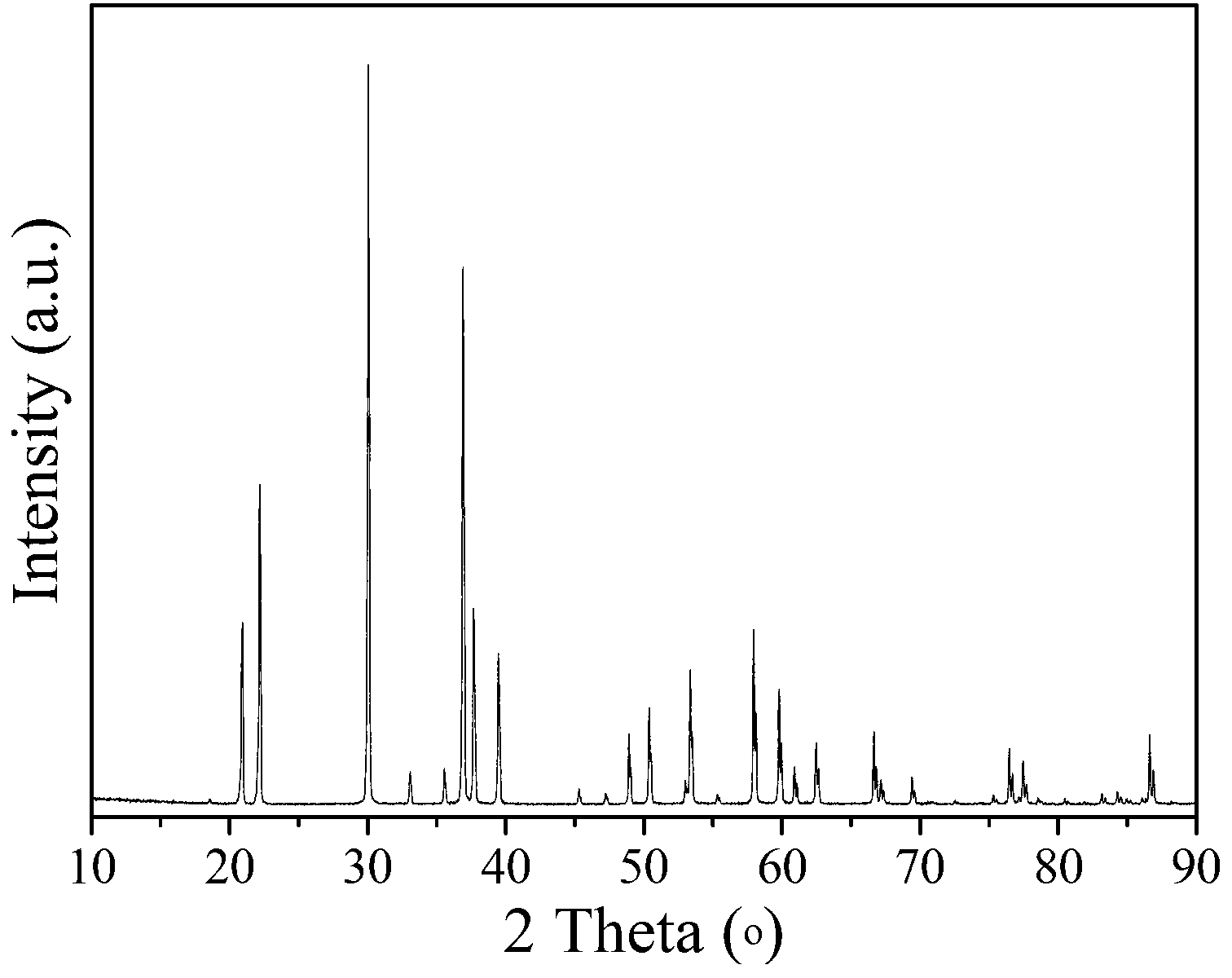

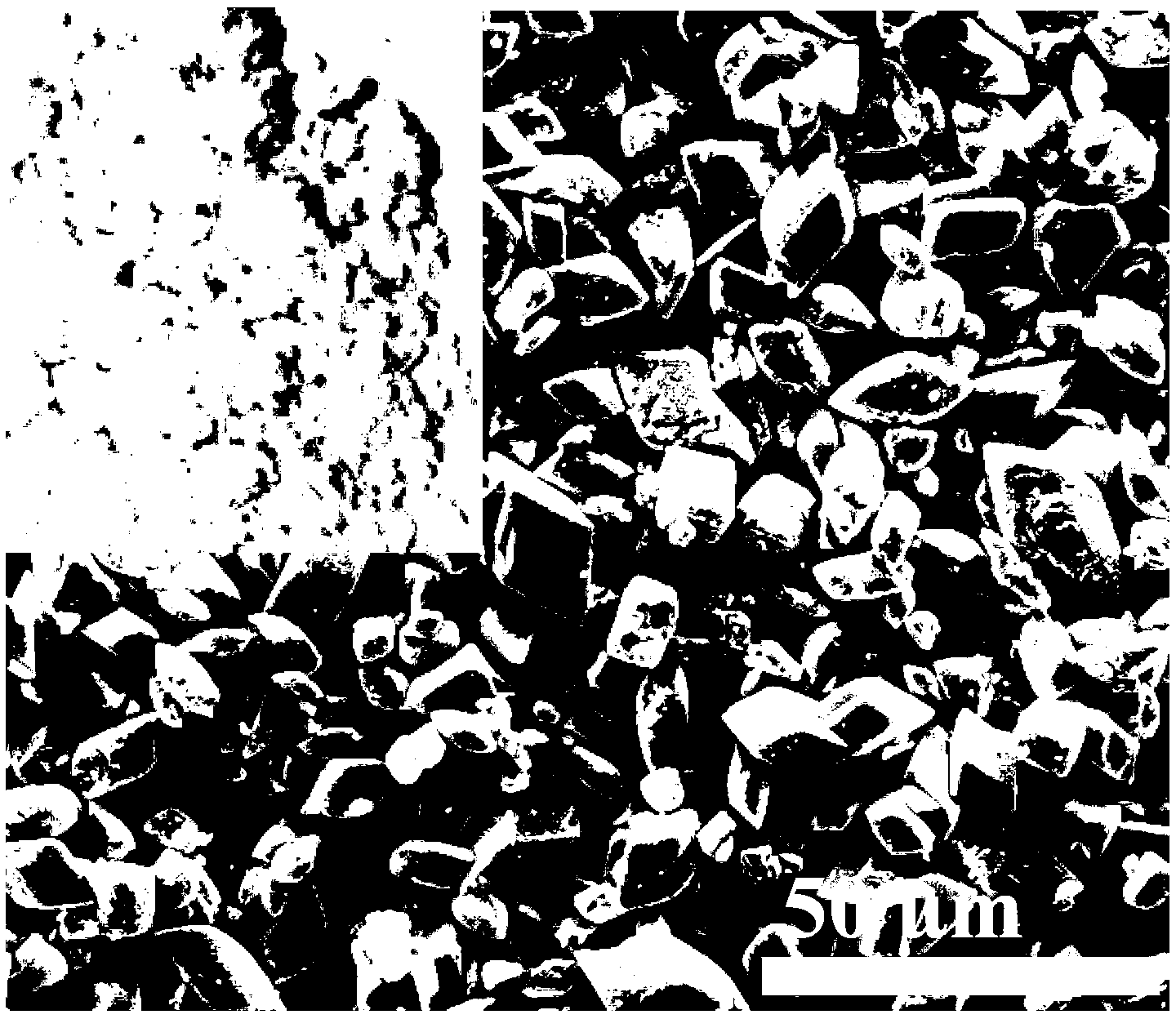

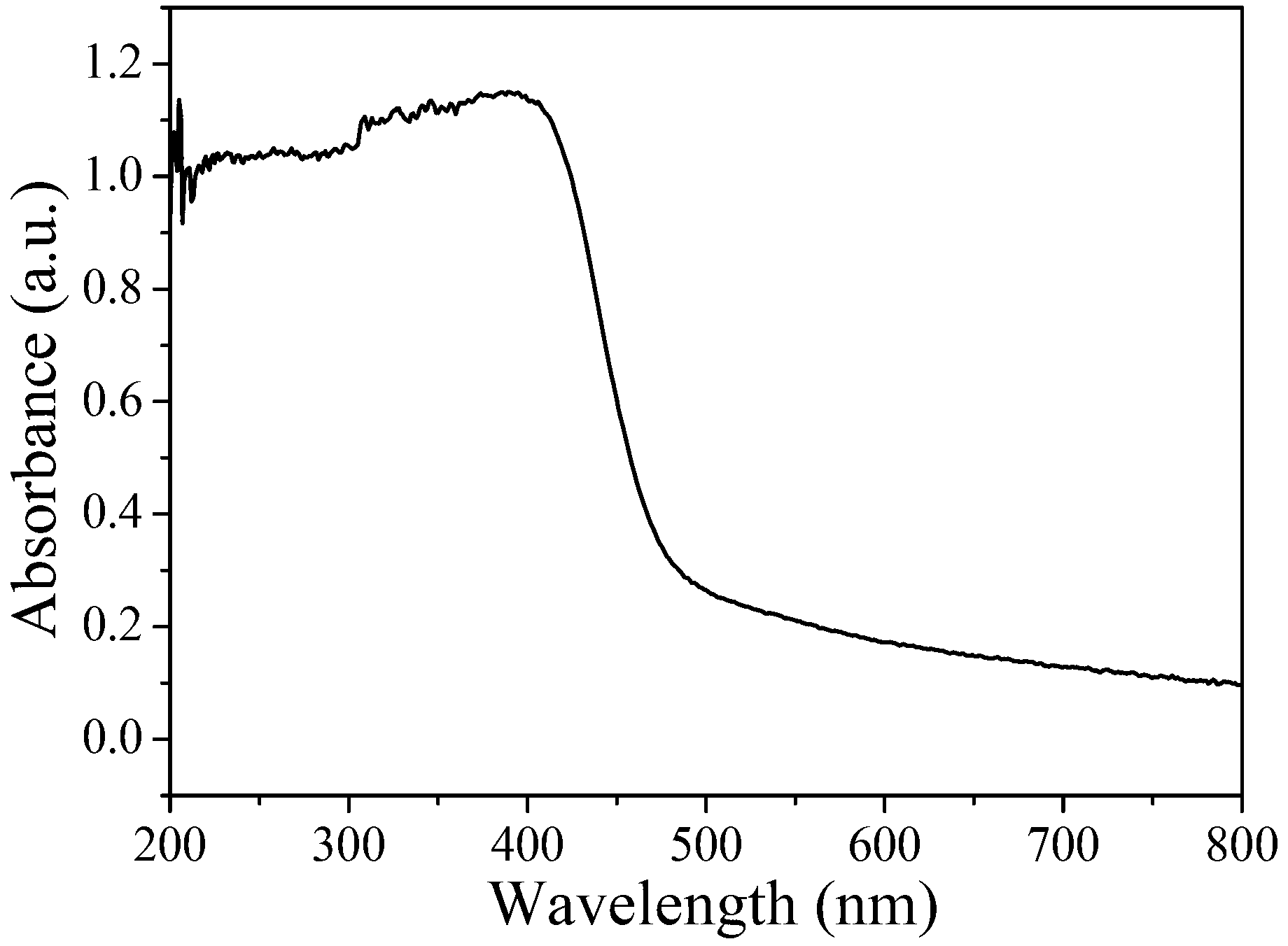

[0024] Weigh out AgNO 3 、KIO 4 Place in different beakers, dissolve AgNO with deionized water to a concentration of 0.1mol / L 3 solution and KIO at a concentration of 0.005mol / L 4 After the solution, put it into two separatory funnels; use concentrated nitric acid to prepare nitric acid with a concentration of 1.0mol / L; under the conditions of room temperature, dark light and magnetic stirring, adopt the co-current precipitation method to separate the AgNO 3 Solution and KIO 4 Preparation of Photocatalytically Active Yellow Precipitate AgIO by Solution Reaction 4 ; The dropping speed is 1-3d / s. During the titration process, the pH of the mixture is controlled to be 1-3 with the prepared nitric acid at the same time. After the titration is completed, continue magnetic stirring for 2 hours at room temperature in the dark. During the reaction of the mixture, the mass ratio of the concentration substances of silver nitrate solution, potassium periodate solution and nitric acid ...

Embodiment 2

[0026] Weigh out AgNO 3 、KIO 4 Placed in different beakers, dissolved in deionized water to make AgNO with a concentration of 0.2mol / L 3 solution and KIO at a concentration of 0.01mol / L 4 After the solution, put it into two separatory funnels; use concentrated nitric acid to prepare nitric acid with a concentration of 2.0mol / L; under the conditions of room temperature, dark light and magnetic stirring, adopt the co-current precipitation method to separate the AgNO 3 Solution and KIO 4 Preparation of Photocatalytically Active Yellow Precipitate AgIO by Solution Reaction 4 ; The dropping speed is 1-3d / s. During the titration process, the pH of the mixture is controlled to be 1-3 with the prepared nitric acid at the same time. After the titration is completed, continue magnetic stirring for 2 hours at room temperature in the dark. During the reaction of the mixture, the mass ratio of the concentration substances of silver nitrate solution, potassium periodate solution and nit...

Embodiment 3

[0028] Weigh out AgNO 3 、KIO 4 Placed in different beakers, dissolved in deionized water to prepare AgNO with a concentration of 0.3mol / L 3 solution and KIO at a concentration of 0.015mol / L 4 After the solution, put it into two separating funnels; use concentrated nitric acid to prepare nitric acid with a concentration of 3.0mol / L; under the conditions of room temperature, dark light and magnetic stirring, the AgNO 3 Solution and KIO 4 Preparation of Photocatalytically Active Yellow Precipitate AgIO by Solution Reaction 4 ; The dropping speed is 1-3d / s. During the titration process, the pH of the mixture is controlled to be 1-3 with the prepared nitric acid at the same time. After the titration is completed, continue magnetic stirring for 2 hours at room temperature in the dark. During the reaction of the mixture, the mass ratio of the concentration substances of silver nitrate solution, potassium periodate solution and nitric acid is controlled to be 20:1:200. The yellow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com