Fire retardant, preparation method thereof and application thereof in polyvinyl chloride (PVC) wire and cable materials

A flame retardant and reaction technology, applied in the field of flame retardant for PVC wire and cable material and its preparation, can solve the problems of large addition amount, deterioration of flame retardant product performance, low flame retardant effect, etc. Excellent flame retardant properties, easy to store

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] This example provides a flame retardant, which is prepared through the following steps:

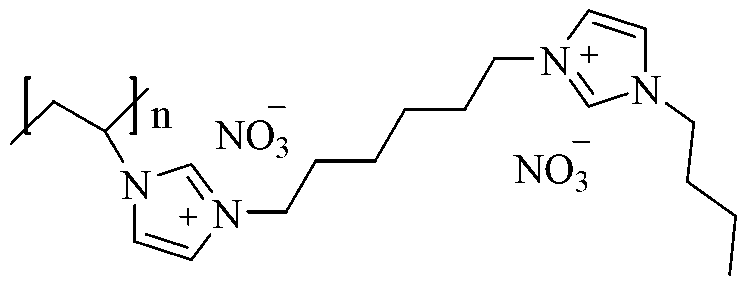

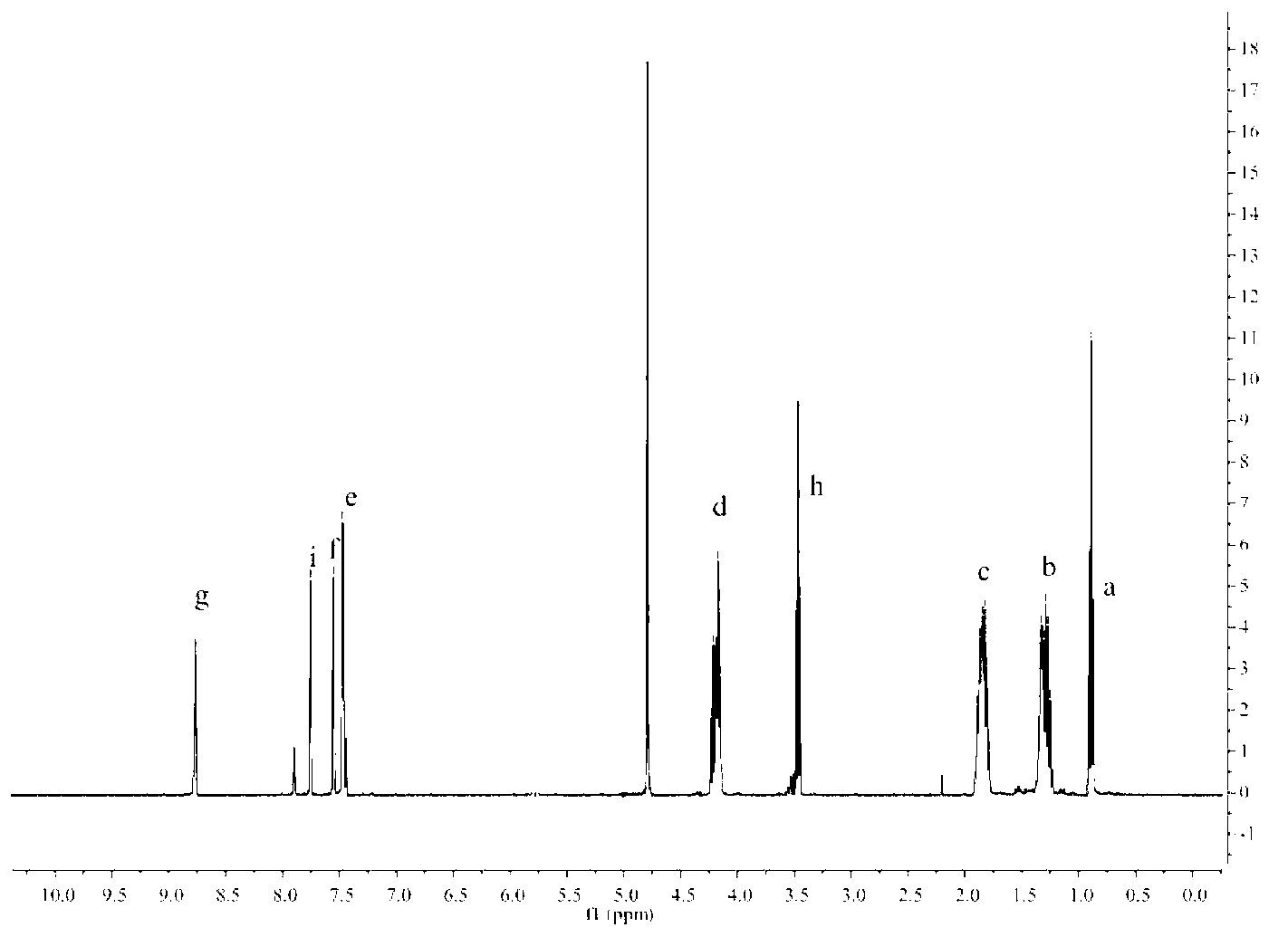

[0031] (1) 3.78g bis-imidazolium ionic liquid monomer ( ) and 1.42gNa 2 HPO 4 Added to 100ml of acetone, stirred and reacted at room temperature for 48 hours, filtered, and rotary evaporated to obtain product a;

[0032] (2) Dissolve 1 g of product a in ethanol, add 0.02 g of azobisisobutyronitrile, and react in an inert gas atmosphere at 60°C for 24 hours, then pour the reaction system into acetone, and the product is precipitated, filtered, washed, The flame retardant is obtained after drying.

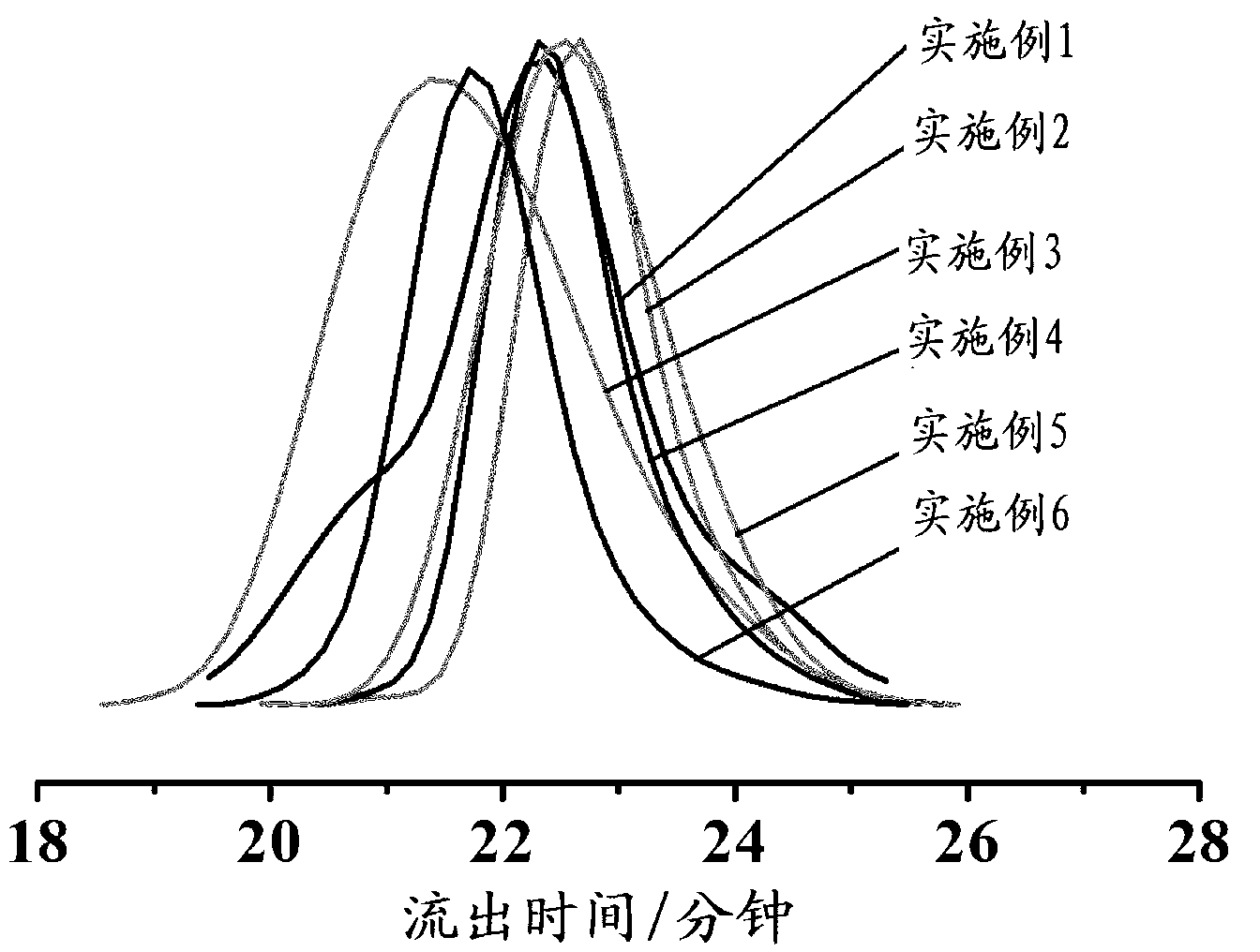

[0033] Gained flame retardant number average molecular weight Mn is 4200g / mol, Mw / Mn value is 2.14, and its gel permeation chromatogram curve sees figure 1 .

Embodiment 2

[0035] This example provides a flame retardant, which is prepared through the following steps:

[0036] (1) 3.78g bis-imidazolium ionic liquid monomer ( ) and 2.4gNaH 2 PO 4 Added to 100ml of acetone, stirred and reacted at room temperature for 72 hours, filtered, and rotary evaporated to obtain product a;

[0037] (2) Dissolve 1 g of product a in ethanol, add 0.005 g of azobisisobutyronitrile, and react in an inert gas atmosphere at 75°C for 5 hours, then pour the reaction system into acetone, and the product is precipitated, filtered, washed, Dry to flame retardant.

[0038] Gained flame retardant number average molecular weight Mn is 7100g / mol, and Mw / Mn value is 1.27, and its gel permeation chromatogram curve sees figure 1 .

Embodiment 3

[0040] This example provides a flame retardant, which is prepared through the following steps:

[0041] (1) 3.78g bis-imidazolium ionic liquid monomer ( ) and 2.02gNa 2 B 4 o 7 Added to 100ml of acetone, stirred and reacted at room temperature for 72 hours, filtered, and rotary evaporated to obtain product a;

[0042] (2) Dissolve 1 g of product a in ethanol, add 0.02 g of azobisisobutyronitrile, react in an inert gas atmosphere at 65°C for 10 hours, then pour the reaction system into acetone, and the product is precipitated, filtered, washed, Serve dry.

[0043] Gained flame retardant Mn is 8050g / mol, and Mw / Mn value is 1.31, and its gel permeation chromatogram curve is shown in figure 1 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| limiting oxygen index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com