Coal-mine gas drainage hole drilling/sealing material and preparation method thereof

A technology for extracting drilling and sealing materials, which can be used in drilling compositions, chemical instruments and methods, etc. The effect of good density, high compressive strength and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

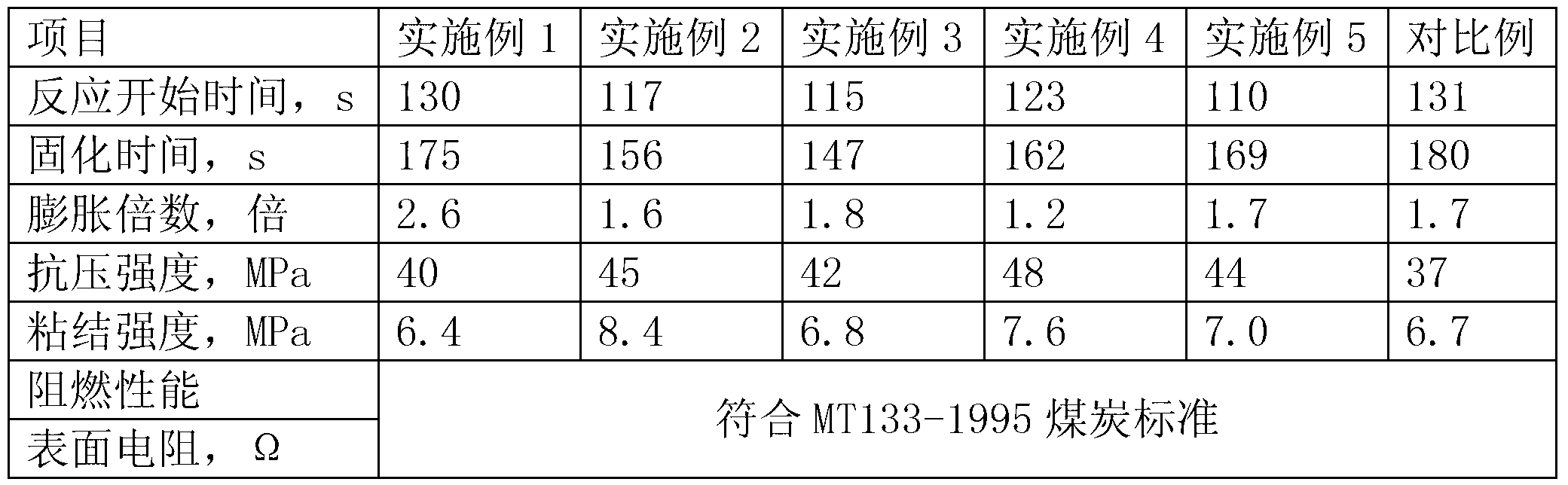

Examples

Embodiment 1

[0062] Example 1: Weigh 60 parts of polyether polyol A: polyoxypropylene triol NJ-303 (hydroxyl value 475 mgKOH / g, Jurong Ningwu New Material Development Co., Ltd.), polyether polyol B: polyoxypropylene polyol Alcohol NJ-8211 (hydroxyl value 420mgKOH / g, Jurong Ningwu New Material Development Co., Ltd.) 40 parts, polyether polyol C: polyoxypropylene polyol NJ-405A (hydroxyl value 475mgKOH / g, Jurong Ningwu New Material Development Co., Ltd.) 5 parts, stir evenly in the mixing tank, then dibutyltin dilaurate (American Gas Company) 0.5 parts, triethylenediamine (American Gas Company) 1.8 parts, HCFC-245fa (American Honeywell Company) ) 5 parts, silicone oil DC-193 (American Air Company) 2.5 parts, antistatic agent JWK-1801 (Wuxi Juwang Plastic Materials Co., Ltd.) 2.5 parts, flame retardant ethyl diethyl phosphate 25 parts, add the above In the mixed solution, continue to stir evenly at high speed to obtain component A. Weigh 180 parts of polyphenylpolymethylene polyisocyanate (P...

Embodiment 2

[0063] Example 2: Weigh 90 parts of polyether polyol A: polyoxypropylene triol NJ-303 (hydroxyl value 475 mgKOH / g, Jurong Ningwu New Material Development Co., Ltd.), polyether polyol B: polyoxypropylene polyol Alcohol NJ-8211 (hydroxyl value 430mgKOH / g, Jurong Ningwu New Material Development Co., Ltd.) 20 parts, polyether polyol C: polyoxypropylene polyol NJ-405A (hydroxyl value 475mgKOH / g, Jurong Ningwu New Material Development Co., Ltd.) 12 parts, stir in the mixing tank evenly, then add 0.5 parts of N, N-dimethylcyclohexylamine (Shanghai Yutian Chemical Co., Ltd.), 2 parts of triethylenediamine (American Gas Company), 3 parts of HCFC-141b (Zhejiang Hangzhou Fushite Chemical Co., Ltd.), 2 parts of silicone oil DC-193 (American Air Company), 2.7 parts of antistatic agent Anti-static Q617 (Dongguan Deshiken Shoe Material Co., Ltd.), Add 22 parts of flame retardant melamine polyphosphate into the above mixed solution, and continue stirring at high speed to obtain component A. ...

Embodiment 3

[0064] Example 3: Weigh 90 parts of polyether polyol A: polyoxypropylene triol NJ-303 (hydroxyl value 475 mgKOH / g, Jurong Ningwu New Material Development Co., Ltd.), polyether polyol B: polyoxypropylene polyol Alcohol NJ-8211 (hydroxyl value 430mgKOH / g, Jurong Ningwu New Material Development Co., Ltd.) 10 parts, polyether polyol C: polyoxypropylene polyol NJ-405A (hydroxyl value 475mgKOH / g, Jurong Ningwu New Material Development Co., Ltd.) 3 parts, stir in the mixing tank evenly, then add 0.5 parts of N, N-dimethylcyclohexylamine (Shanghai Yutian Chemical Co., Ltd.), 2 parts of triethylenediamine (American Gas Company), 3 parts of HCFC-141b (Zhejiang Hangzhou Fushite Chemical Co., Ltd.), 3 parts of silicone oil DC-193 (American Air Company), 3 parts of antistatic agent Anti-static Q617 (Dongguan Deshiken Shoe Material Co., Ltd.), Add 25 parts of flame retardant melamine polyphosphate into the above mixed solution, and continue stirring at high speed to obtain component A. Wei...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com