Rapidly solidified aluminum matrix composite enhanced by SiCp particles, and preparation method thereof

An aluminum-based composite material and particle reinforcement technology, applied in the field of metal materials and composite materials, can solve the problems of low strength, large grain size of composite materials, poor wear resistance, etc., and achieve high strength characteristics, high wear resistance, and good mechanical properties. , combined with good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Step 1, weigh the following components according to the volume ratio: SiC with a particle size of 0.6 μm p 5% particles, and the rest is rapidly solidified ZL102 alloy powder with a particle size of 1.5 μm;

[0040] Step 2, the SiC p The particles were fired at 1100°C in an oxidizing atmosphere for 10h to make SiC p The particle surface is oxidized to form a layer of SiO 2 film, and then use a 5% HF solution to oxidize SiC at high temperature p Particles are cleaned, most preferably with deionized water and dried at 120°C;

[0041] Step 3, the SiC pretreated in step 2 p The particles and the rapidly solidified ZL102 alloy powder were dry-mixed in a ceramic ball mill tank under the protection of argon atmosphere for 5 hours, and the speed of the high-energy ball mill was 200r / min; finally, the high-energy mixed powder was obtained by drying at 120°C;

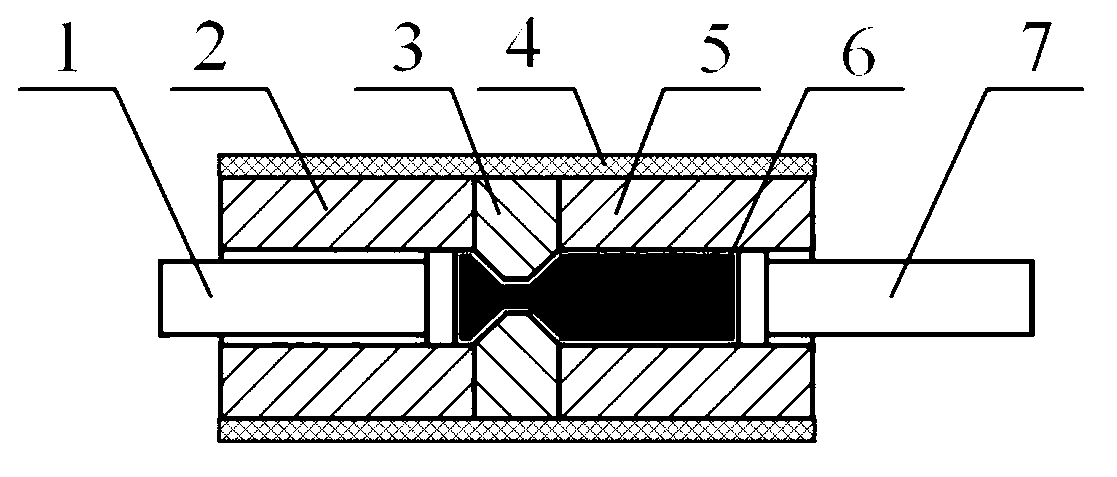

[0042] Step 4, put the high-energy mixed powder obtained in step 3 in a reciprocating extrusion device for pre-comp...

Embodiment 2

[0044] Step 1, weigh the following components according to the volume ratio: SiC with a particle size of 0.3 μm p 10% of particles, the rest is rapidly solidified ZL301 alloy powder with a particle size of 2 μm;

[0045] Step 2, the SiC p The particles were fired at 1100°C in an oxidizing atmosphere for 10h to make SiC p The particle surface is oxidized to form a layer of SiO 2 film, and then use a 5% HF solution to oxidize SiC at high temperature p Particles are cleaned, most preferably with deionized water and dried at 120°C;

[0046] Step 3, the SiC pretreated in step 2 p Granules and rapidly solidified ZL301 alloy powder were wet-mixed in a ceramic ball mill tank using a mixture of absolute ethanol and 2% polyethylene glycol as a wet mix for 1 hour, the speed of the high-energy ball mill was 300r / min, and the amount of wet mix added was SiC p 20% of the total volume of particles and rapidly solidified ZL301 alloy powder, and finally dried at 60°C to obtain high-energ...

Embodiment 3

[0049] Step 1, weigh the following components according to the volume ratio: SiC with a particle size of 0.6 μm p 5% particles, and the rest is rapidly solidified ZL201 alloy powder with a particle size of 2 μm;

[0050] Step 2, the SiC p The particles were fired at 1100°C in an oxidizing atmosphere for 10h to make SiC p The particle surface is oxidized to form a layer of SiO 2 film, and then use a HF solution with a concentration of 20% to oxidize SiC at high temperature p Particles are cleaned, most preferably with deionized water and dried at 120°C;

[0051] Step 3, the SiC pretreated in step 2 p Granules and rapidly solidified ZL201 alloy powder were wet-mixed for 5 hours using a mixture of absolute ethanol and 2% polyethylene glycol as a wet mixture in a ceramic ball mill tank. The speed of the high-energy ball mill was 250r / min. SiC p 30% of the total volume of particles and rapidly solidified ZL201 alloy powder, and finally dried at 60°C to obtain high-energy mixe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com