Wc-cr3c2-ni thermal spray powder and its preparation method and use

A technology of wc-cr3c2-ni and thermal spraying powder, which is applied in coating, fusion spraying, metal material coating process, etc., can solve problems such as brittleness, cavitation performance limitation, thermal spraying powder needs to be improved, and achieve improvement Correlation performance, low oxygen content, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

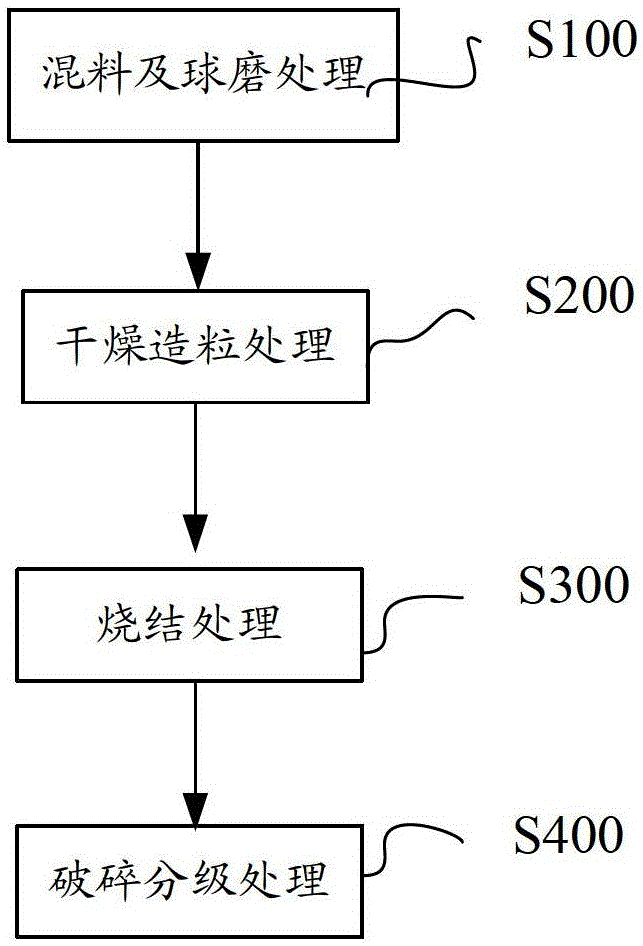

Method used

Image

Examples

Embodiment 1

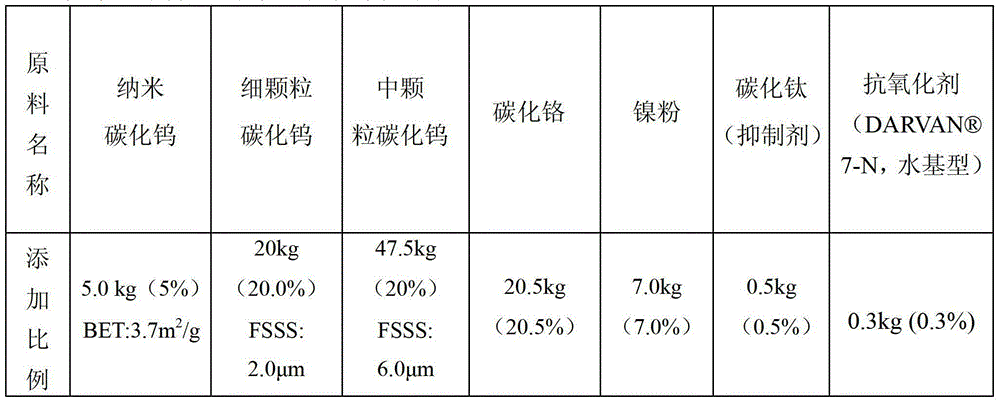

[0050] This embodiment refers to the above-mentioned general method, taking the production of 100kg spray powder as an example, and preparing the WC-Cr of the present invention according to the following process steps 3 C 2 -Ni Thermal Spray Powder:

[0051] Among them, the ratio of raw materials and corresponding parameters are shown in the table below.

[0052]

[0053] Note: BET: refers to the BET test method, that is, the BET specific surface area test method, where the specific surface area refers to the total area of a unit mass of material. In the above table, the BET value measured by the BET test method is used to characterize the particle size of the nano-tungsten carbide with spherical porous structure used in the present invention.

[0054] FSSS: The abbreviation of Fischer particle size test, the basic method is the steady flow air permeation method, that is, the specific surface area and average particle size are measured under the condition of constant ai...

Embodiment 2

[0090] Taking the production of 100kg spray powder as an example, prepare the WC-Cr of the present invention according to the method described in Example 1 3 C 2 -Ni thermal spray powder, wherein, the difference from Example 1 is: have the raw material ratio and corresponding parameters shown in the following table; add deionized water that accounts for 25% of the raw material mass percentage and a temperature of 10-15 ° C 25kg and 1.0kg (1.0%) of polyvinyl alcohol; the sintering temperature is 1270°C. Thus, the preparation obtains the final product WC-Cr 3 C 2 -Ni thermal spraying powder, wherein the particle size specification is 40kg of 5-30 microns, 58kg of 15-45 microns, the metal loss is about 2kg (2.0%) during the production process, and the bulk density of the powder is 4.2-4.4g / cm 3 .

[0091]

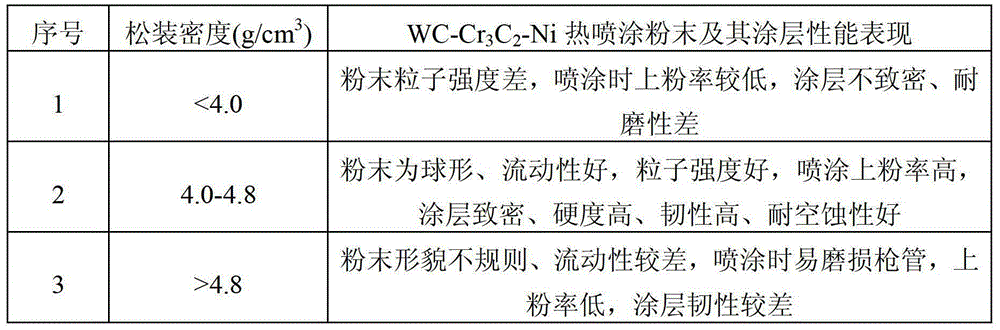

[0092] Then, combined with the visual observation and the performance test after the coating was prepared by spraying, the new WC-Cr prepared above was tested and evalu...

Embodiment 3

[0115] Taking the production of 100kg spray powder as an example, prepare the WC-Cr of the present invention according to the method described in Example 1 3 C 2 -Ni thermal spray powder, wherein, the difference from Example 1 is: have the raw material ratio and corresponding parameters shown in the following table; add deionized water that accounts for 25% of the raw material mass percentage and a temperature of 10-15 ° C 25kg and 1.0kg (1.0%) of polyvinyl alcohol; the speed of pushing the boat is 12 minutes / boat, and the sintering temperature is 1280°C. Thus, the preparation obtains the final product WC-Cr 3 C 2 -Ni thermal spraying powder, of which the particle size specification is 35kg of 10-38 microns, 63kg of 15-53 microns, the metal loss is about 2kg (2.0%) during the production process, and the bulk density of the powder is 4.4-4.6g / cm 3 .

[0116]

[0117] Then, combined with the visual observation and the performance test after the coating was prepared by spr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com