Vacuum deposition type high-rigidity smooth steel stainless decorative board for mirror surface

A technology of vacuum deposition and stainless steel, which is applied in the direction of special decorative structure, decorative art, superimposed layer plating, etc. Excellent wear and scratch resistance, excellent film structure effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

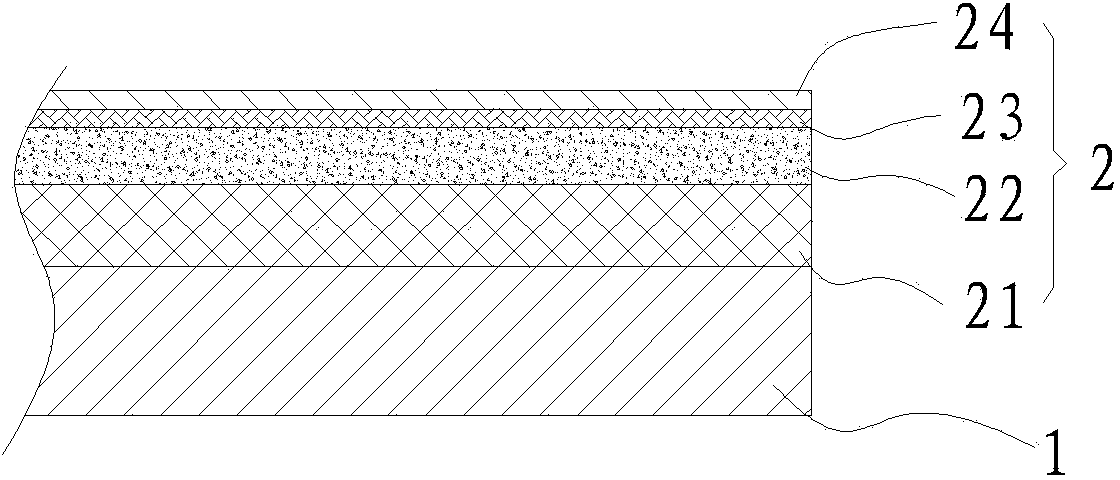

[0031] Example 1: Preparation of high-hard and smooth golden stainless steel mirror decorative plate by vacuum deposition

[0032] The stainless steel plate is in a continuous high-temperature baking furnace, filled with carbon dioxide gas, carburized at a temperature of 550 degrees Celsius, and carburized for 20 minutes to obtain a hardened layer of 25um thick carburized stainless steel plate; then put the stainless steel plate into a vacuum coating machine, Vacuum nitrogen ion implantation is carried out, the implantation conditions are: vacuum degree 0.7~1*10 -2 pa, the ion source voltage is 100KV, the implantation time is 2min, and a layer of 2.5um ion treatment hardening layer is obtained through the vacuum nitrogen ion implantation reaction; then vacuumize to 0.6*10 -2 pa, arc ion plating a layer of color film, the coating conditions are: arc target coating current 70A, bias voltage 120V, time 6min, to obtain a layer of 0.5 um vacuum deposited color film; finally obta...

Embodiment 2

[0033] Example 2: The stainless steel plate is in a continuous high-temperature baking furnace, filled with carbon dioxide gas, carburized at a temperature of 550 degrees Celsius, and carburized for 10 minutes to obtain a hardened layer of 10um thick carburized stainless steel plate; then put the stainless steel plate into a vacuum coating machine, Vacuum nitrogen ion implantation is carried out, the implantation conditions are: vacuum degree 0.7~1*10 -2 pa, the ion source voltage is 110KV, the implantation time is 1min, and a layer of 1um ion treatment hardening layer is obtained through the vacuum nitrogen ion implantation reaction; then vacuumize to 0.6*10 -2 pa, arc ion plating a layer of color film, the coating conditions are: arc target coating current 60A, bias voltage 200V, time 2min, to obtain a layer of 0.1 um vacuum deposited color film; finally obtained by ion glow siloxane Transparent silicone protective film, coating conditions: Hexamethyldisiloxane gas 100SCCM...

Embodiment 3

[0034] Example 3:The stainless steel plate is in a continuous high-temperature baking furnace, filled with carbon dioxide gas, carburized at a temperature of 550 degrees Celsius, and carburized for 30 minutes to obtain a hardened layer of 50um thick carburized stainless steel plate; then put the stainless steel plate into a vacuum coating machine, Vacuum nitrogen ion implantation is carried out, the implantation conditions are: vacuum degree 0.7~1*10 -2 pa, the ion source voltage is 120KV, the implantation time is 10min, and a layer of 5um ion-treated hardened layer is obtained through the vacuum nitrogen ion implantation reaction; then vacuumize to 0.6*10 -2 pa, arc ion plating a layer of color film, the coating conditions are: arc target coating current 110A, bias voltage 100V, time 15min, to obtain a layer of 0.1 um vacuum deposited color film; finally obtained by ion glow siloxane Transparent silicone protective film, the coating conditions: 500SCCM of octamethyltrisilox...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com