Electrochemical method for synthesizing 2,2'-dichlorohydrazobenzene by use of supported catalyst ionic membrane

A dichlorohydroazobenzene and dichlorohydroazo technology, which is applied in the field of organic electrochemical synthesis, can solve the problems of long reaction time, short working life of nickel foam, and increased power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

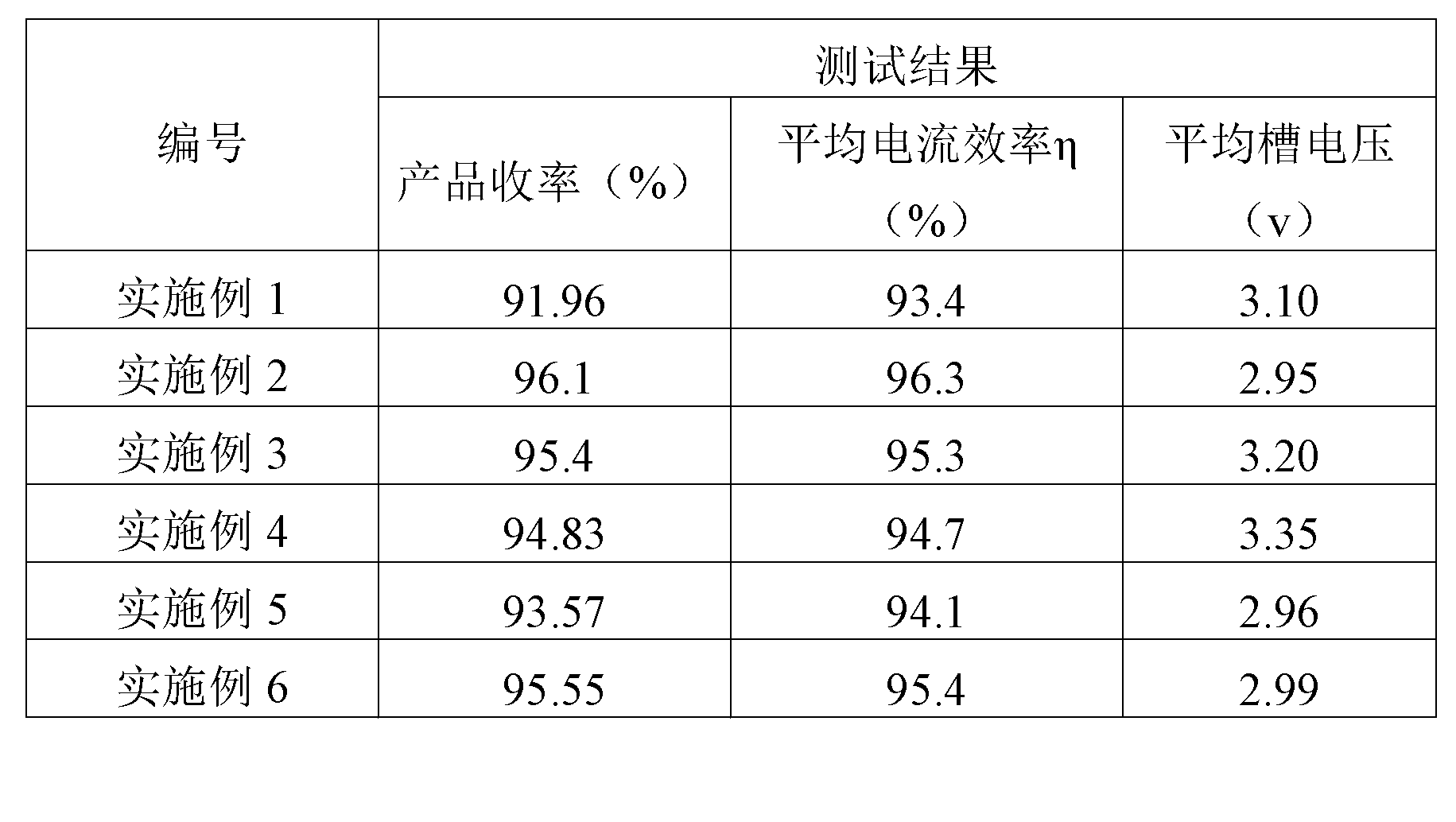

Examples

Embodiment 1

[0015] Preparation of perfluorosulfonic acid ion exchange membrane:

[0016] First, ultrasonically mix 5 g of perfluorosulfonic acid resin with a mass ratio of 5:1 and N,N-dimethylformamide until there are no more bubbles in the solution. Put a polytetrafluoroethylene (PTFE) mesh cloth with a size of 8 cm × 10 cm in a water bath at 80 ° C, and first use 3% H 2 o 2 Soak in the solution for 30min, then use 0.5mol / L H 2 SO 4 The solution was soaked for 30 minutes, and finally put into a drying oven for drying treatment. Secondly, the casting method is used to scrape the film, and the pretreated PTFE mesh is spread on the glass plate, and the prepared mixed solution is used to scrape the film. Finally, a perfluorosulfonic acid ion exchange membrane is prepared.

[0017] The perfluorosulfonic acid ion-exchange membrane is applied to the electrochemical synthesis of 2,2'-dichlorohydroazobenzene. The ion-exchange membrane is closely attached to the anode plate and separated from...

Embodiment 2

[0019] Modification of perfluorosulfonic acid ion exchange membrane:

[0020] First prepare graphite into graphene oxide (Graphene), then reduce the mixed solution of graphene oxide and chloroplatinic acid with sodium ascorbate (VC), and prepare Pt / Graphene with a mass ratio of Pt to graphene of 3:10 The catalyst has a particle size of 1.99nm; 5g of a mixed solution of perfluorosulfonic acid resin and N,N-dimethylformamide with a mass ratio of 5:1 and 0.1g of the prepared Pt / Graphene catalyst are ultrasonically mixed, until there are no more bubbles in the solution. Secondly, the casting method is used to scrape the film. Spread the polytetrafluoroethylene mesh cloth after impurity removal on the glass plate, and use the prepared mixed solution to scrape the film. Finally, a graphene-supported platinum ion exchange membrane with a metal platinum loading of 30% was prepared.

[0021] The graphene-supported platinum ion exchange membrane is applied to the electrochemical synt...

Embodiment 3

[0023] Modification of perfluorosulfonic acid ion exchange membrane:

[0024] First prepare graphite into graphene oxide (Graphene), then reduce the mixed solution of graphene oxide and chloroplatinic acid with sodium ascorbate (VC), and prepare Pt / Graphene with a mass ratio of Pt to graphene of 2:10 The catalyst has a particle size of 4.58nm; 5g of a mixed solution of perfluorosulfonic acid resin and N,N-dimethylformamide with a mass ratio of 5:1 and 0.1g of the prepared Pt / Graphene catalyst are ultrasonically mixed, until there are no more bubbles in the solution. Secondly, the casting method is used to scrape the film. Spread the polytetrafluoroethylene mesh cloth after impurity removal on the glass plate, and use the prepared mixed solution to scrape the film. Finally, a graphene-supported platinum ion exchange membrane with a metal platinum loading of 20% was prepared. The graphene-supported platinum ion exchange membrane was applied to the electrochemical synthesis of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com