Simply-supported box girder bridge strengthening method with oblique cables

An oblique cable method and simply supported technology, which is applied in bridge reinforcement, bridge construction, etc., can solve the problems of reduced structural durability, reduced mechanical performance of bridges, and oblique cracks in the web, so as to improve the flatness and Comfort, prevent further cracking, achieve sustainable results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with accompanying drawing.

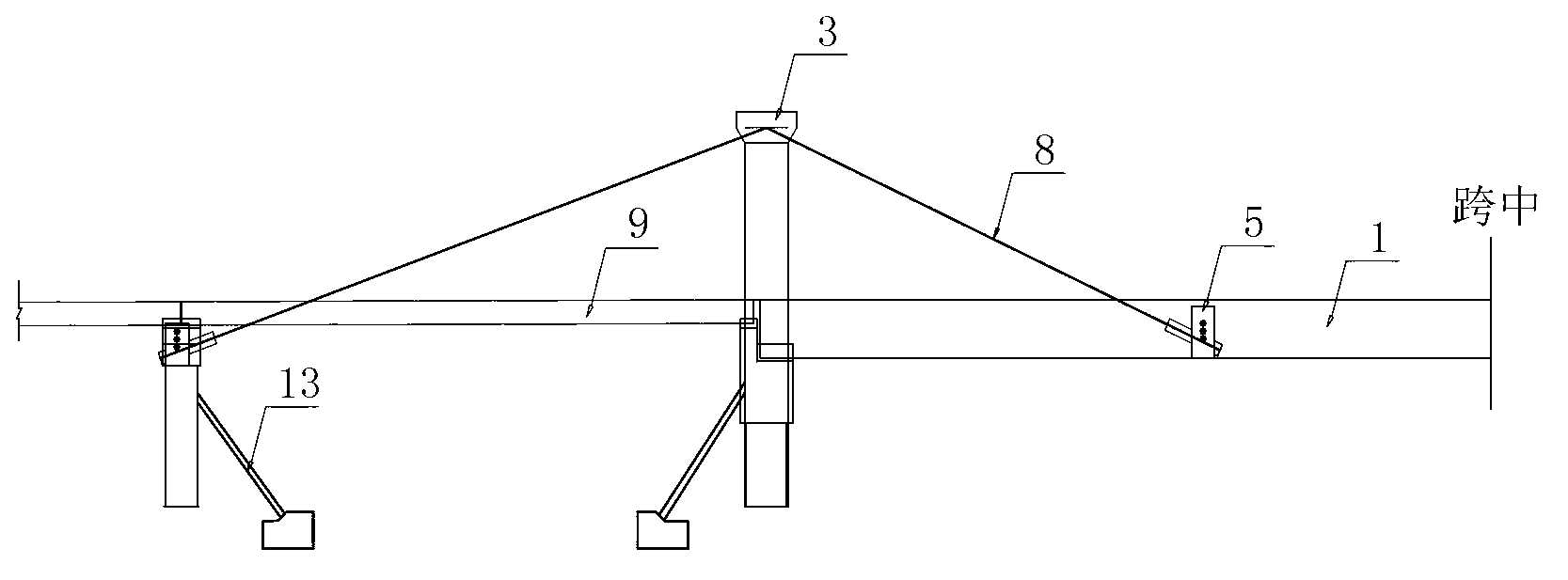

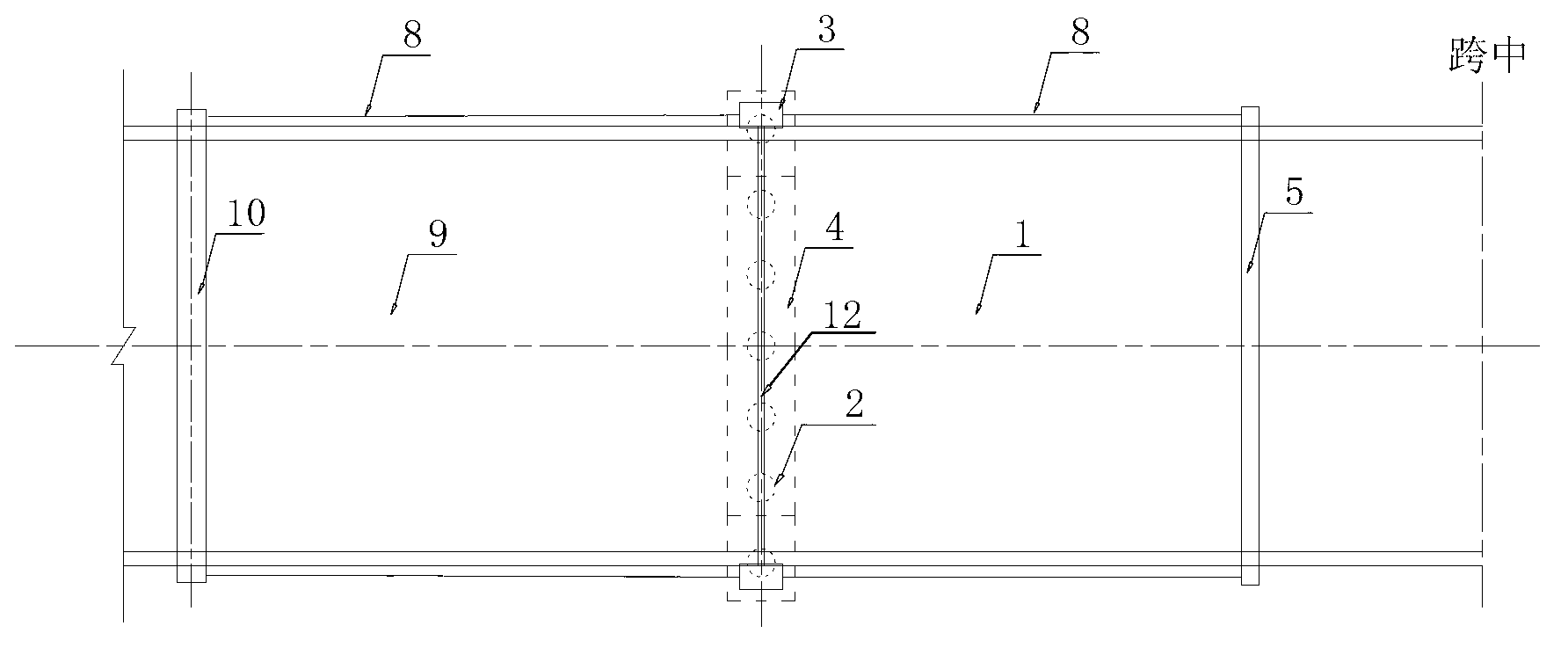

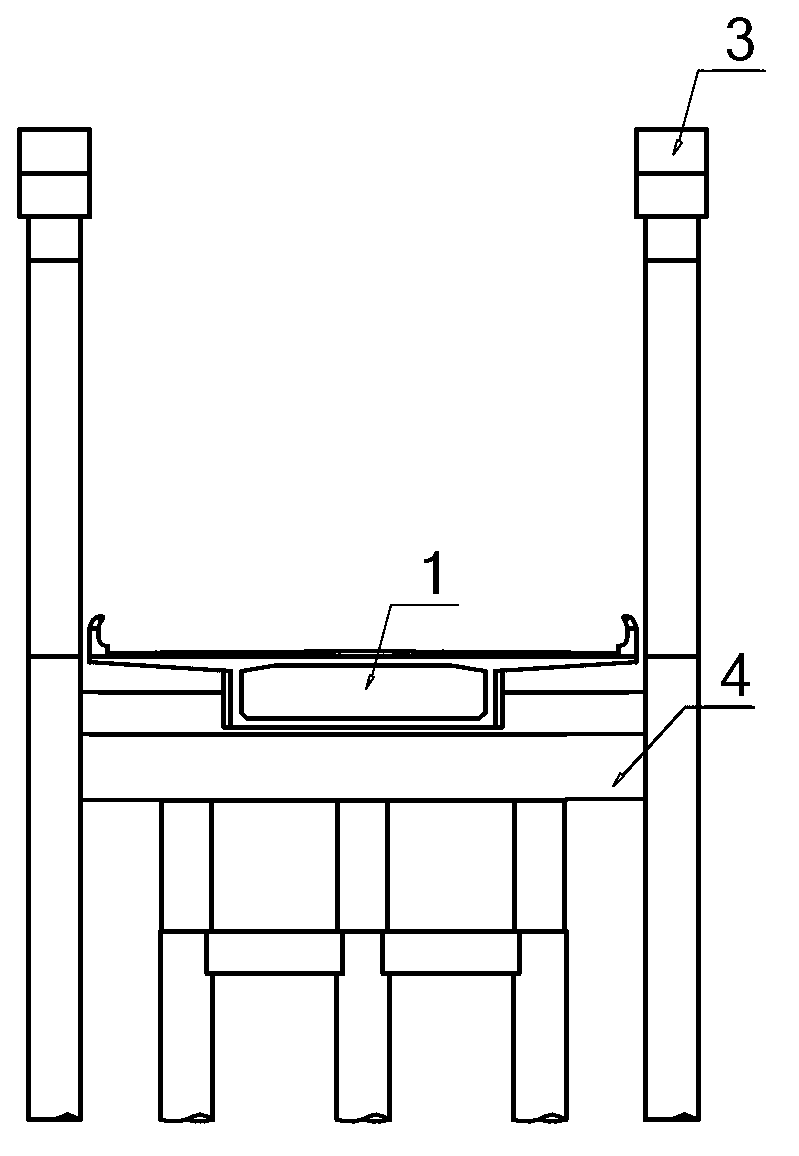

[0029] Such as figure 1 , 2 , 3, 4, 5, 6, and 7 show a method for reinforcing simply supported box girder bridges with inclined cables, which are useful in the implementation process: prestressed simply supported box girder 1, simply supported box girder pile foundation 2, steel bars Concrete tower column 3, combined cover beam 4, reinforced beam 5, transverse prestressed pipe 6, transverse prestressed steel strand 7, cable-stayed steel cable 8, prestressed hollow slab beam 9, side span cover beam 10, horizontal prestressed Pull rod 11, former bridge expansion joint 12, diagonal brace 13; Its specific implementation steps are as follows:

[0030] Step (1). Pile foundations are added on both sides of the simply supported box beam pile foundation 2, and the added pile foundation and the implanted steel bars of the original simply supported box beam pile foundation 2 are int...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com