Method for producing hydrolyzed wheat protein

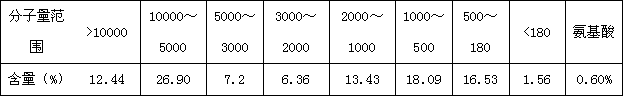

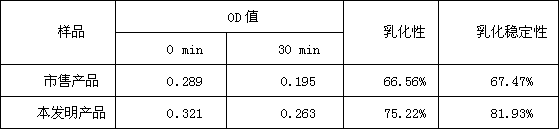

A technology of wheat hydrolyzed protein and production method, which is applied in the field of comprehensive development and application of wheat deep processing, which can solve the problems of high price of wheat hydrolyzed protein, difficulty in controlling the enzymatic hydrolysis process, difficult separation of target products, etc., and achieve low free amino acid content and high degree of hydrolysis Appropriate, soft-tasting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] A kind of production method of wheat hydrolyzed protein of the present invention, comprises the following steps:

[0020] a, preparation of enzymolysis solution: add 3000g of water into the reaction kettle, heat to 50°C, add 400g of gluten powder to the reaction kettle at a ratio of 8 U / g gluten powder, and add compound protease at 100r Stir at a speed of 1 / min, the stirring time is 2 minutes, then add 300g gluten powder, stir at a speed of 250r / min, the stirring time is 6 minutes, then add 300g gluten powder, stir at a speed of 400r / min, add alkali to adjust the pH Value, the range of pH value is 7.0-7.5, after reacting for 20 minutes, add medium temperature amylase according to the amount of 2U / g gluten powder, stir at 300r / min speed, after reacting for 10 minutes, according to the amount of 30U / g gluten powder Add glucoamylase in an appropriate amount, stir at 200r / min, and react for 5 minutes. After hydrolysis, raise the temperature of the enzymolysis solution to 75...

Embodiment 2

[0026] A kind of production method of wheat hydrolyzed protein of the present invention, comprises the following steps:

[0027] a, the preparation of enzymolysis solution: the water of 3000g is added in the reactor, is heated to 50-65 ℃, with the gluten powder of 300g, adds compound protease in the ratio of 15 U / g gluten powder in the reactor, Stir at a speed of 400r / min for 5 minutes, then add 400g gluten powder, stir at a speed of 250r / min, stir for 2 minutes, then add 300g of gluten, stir at a speed of 100r / min, add alkali Adjust the pH value, the range of pH value is 7.0-7.5, after reacting for 40 minutes, add medium temperature amylase according to the amount of 3U / g gluten powder, stir at 300r / min, after reacting for 15 minutes, according to the amount of 40U / g gluten Add glucoamylase to the amount of powder, and keep stirring at a stirring speed of 200r / min. React for 10 minutes. After hydrolysis, heat the enzymolysis solution to 85°C and keep it for 6 minutes. Cool t...

Embodiment 3

[0033] A kind of production method of wheat hydrolyzed protein of the present invention, comprises the following steps:

[0034] a. Preparation of enzymolysis solution: add 3000g of water into the reactor, heat to 65°C, add 300g of gluten powder to the reactor at a ratio of 20 U / g gluten powder, and add compound protease at 400r Stir at a speed of 1 / min, the stirring time is 8 minutes, then add 300g gluten powder, stir at a speed of 300r / min, the stirring time is 6 minutes, then add 400g gluten powder, stir at a speed of 100r / min, add alkali to adjust the pH value, the range of pH value is 7.0-7.5, after reacting for 60 minutes, add medium temperature amylase according to the amount of 5U / g gluten powder, stir at 400r / min speed, after reacting for 20 minutes, according to the amount of 50U / g gluten powder Add glucoamylase in an appropriate amount, and keep stirring, the stirring speed is 400r / min, and react for 15 minutes. Liquid cooling to 35°C;

[0035] B, the preparation ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com