Recoverable float type Pt-TiO2/ floating bead photocatalyst and preparation method thereof

A pt-tio2, floating type technology, applied in the field of photocatalytic materials, can solve the problems of waste of resources and difficulty in recycling, and achieve the effects of reducing industrial application costs, simple preparation and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

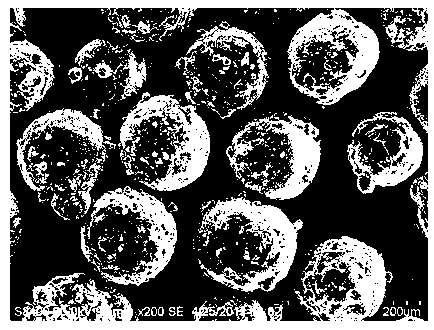

[0031] 1) Pretreatment of floating beads: soak the floating beads extracted from fly ash with 10% dilute nitric acid for 4 hours, and then rinse with distilled water until the outflowing water is neutral, and then use after drying;

[0032] 2) Using butyl titanate, absolute ethanol, acetylacetone and distilled water as raw materials, the molar ratio of butyl titanate, absolute ethanol, acetylacetone and distilled water is 1:25:1:3, and the pH is adjusted with concentrated nitric acid To 5, stir to make it fully react, then add polyethylene glycol 20000 to make the molar ratio of butyl titanate and polyethylene glycol to be 800:1, heat and stir to fully dissolve, that is, to obtain yellow and transparent TiO 2 sol;

[0033] 3) To TiO 2 Add the floating bead carrier pretreated in step 1) to the sol, so that the mass ratio of butyl titanate to the floating beads is 7:1, stir to mix evenly, soak for 12 hours, filter, store the filtrate at a constant temperature, and filter out th...

Embodiment 3

[0038] 1) Pretreatment of floating beads: soak the floating beads extracted from fly ash with 10% dilute nitric acid for 4 hours, and then rinse with distilled water until the outflowing water is neutral, and then use after drying;

[0039] 2) Using butyl titanate, absolute ethanol, acetylacetone and distilled water as raw materials, the molar ratio of butyl titanate, absolute ethanol, acetylacetone and distilled water is 1:25:1:2, and the pH is adjusted with concentrated nitric acid To 6, stir to make it fully react, then add polyethylene glycol 20000 to make the molar ratio of butyl titanate to polyethylene glycol 1000:1, heat and stir to fully dissolve, that is, to obtain yellow and transparent TiO 2 sol;

[0040] 3) To TiO 2 Add the floating bead carrier pretreated in step 1) to the sol, so that the mass ratio of butyl titanate to the floating beads is 10:1, stir to mix evenly, soak for 24 hours, filter, store the filtrate at a constant temperature, and filter out the sampl...

Embodiment 4

[0045] 1) Pretreatment of floating beads: soak the floating beads extracted from fly ash with 10% dilute nitric acid for 4 hours, and then rinse with distilled water until the outflowing water is neutral, and then use after drying;

[0046] 2) Using butyl titanate, absolute ethanol, acetylacetone and distilled water as raw materials, the molar ratio of butyl titanate, absolute ethanol, acetylacetone and distilled water is 1:25:1:1, and the pH is adjusted with concentrated nitric acid To 5, stir to make it fully react, then add polyethylene glycol 20000 to make the molar ratio of butyl titanate to polyethylene glycol 1200:1, heat and stir to fully dissolve, that is, to obtain yellow and transparent TiO 2 sol;

[0047] 3) To TiO 2 Add the floating bead carrier pretreated in step 1) to the sol, so that the mass ratio of butyl titanate to the floating beads is 10:1, stir to mix evenly, soak for 36 hours, filter, store the filtrate at a constant temperature, and filter out the sam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com