Preparation method of silver phosphate photocatalyst

A catalyst and phosphoric acid technology, applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve the problems of low quantum efficiency and low utilization efficiency of TiO2, achieve low cost, simple preparation method, optical The effect of high catalytic activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Take 40ml of polyethylene glycol 200, pour it into a beaker, add 0.002mol of silver acetate and 41μl of phosphoric acid aqueous solution (the phosphoric acid content is 0.0006mol) with a mass percent concentration of 85% under stirring conditions, and use urotropine Adjust the pH of the solution to 5, and react for ten minutes under stirring. After the reaction, the precipitate was collected by centrifugation, washed with absolute ethanol and distilled water in sequence, and dried at 60° C. for 8 hours to obtain photocatalyst 1 .

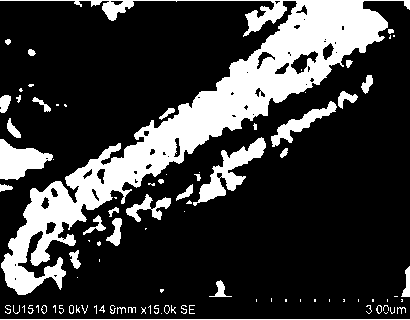

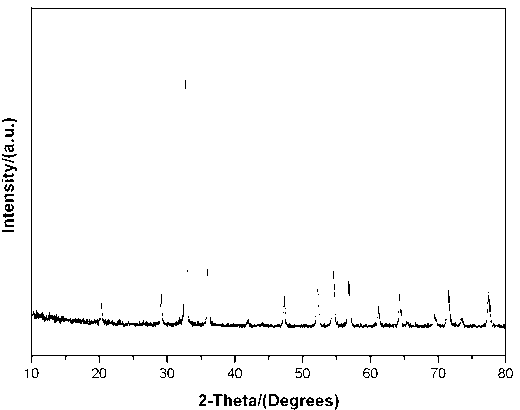

[0023] from image 3 It can be seen that photocatalyst 1 is a pure phase of silver phosphate. from figure 1 and figure 2 It can be seen that the photocatalyst 1 is a hollow tubular microporous structure assembled by a large number of small nanoparticles.

Embodiment 2

[0025] Take 40ml of polyethylene glycol 200, pour it into a beaker, add 0.002mol of silver acetate and 89μl of phosphoric acid aqueous solution with a concentration of 85% by mass (phosphoric acid content is 0.0013mol) under stirring conditions, and use urotropine Adjust the pH of the solution to 5.5, and react for ten minutes under stirring. After the reaction, the precipitate was collected by centrifugation, washed with absolute ethanol and distilled water in sequence, and dried at 70° C. for 7 hours to obtain photocatalyst 2 .

[0026] It can be seen from the X-ray electron diffraction image of the photocatalyst 2 that the photocatalyst 2 is a pure phase of silver phosphate. From the electron microscope topography of photocatalyst 2, it can be seen that photocatalyst 2 is a hollow tubular microporous structure assembled by a large number of nanometer particles.

Embodiment 3

[0028] Take 40ml of polyethylene glycol 200, pour it into a beaker, add 0.002mol of silver acetate and 68μl of phosphoric acid aqueous solution with a mass percentage concentration of 85% (phosphoric acid content is 0.001mol) under stirring conditions, and use urotropine Adjust the pH of the solution to 6, and react for ten minutes under stirring. After the reaction, the precipitate was collected by centrifugation, washed successively with absolute ethanol and distilled water, and dried at 80° C. for 8 hours to obtain catalyst 3 .

[0029] It can be seen from the X-ray electron diffraction image of the photocatalyst 3 that the photocatalyst 3 is a pure phase of silver phosphate. From the electron microscope topography of photocatalyst 3, it can be seen that photocatalyst 3 is a hollow tubular microporous structure assembled by a large number of small nanoparticles.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com