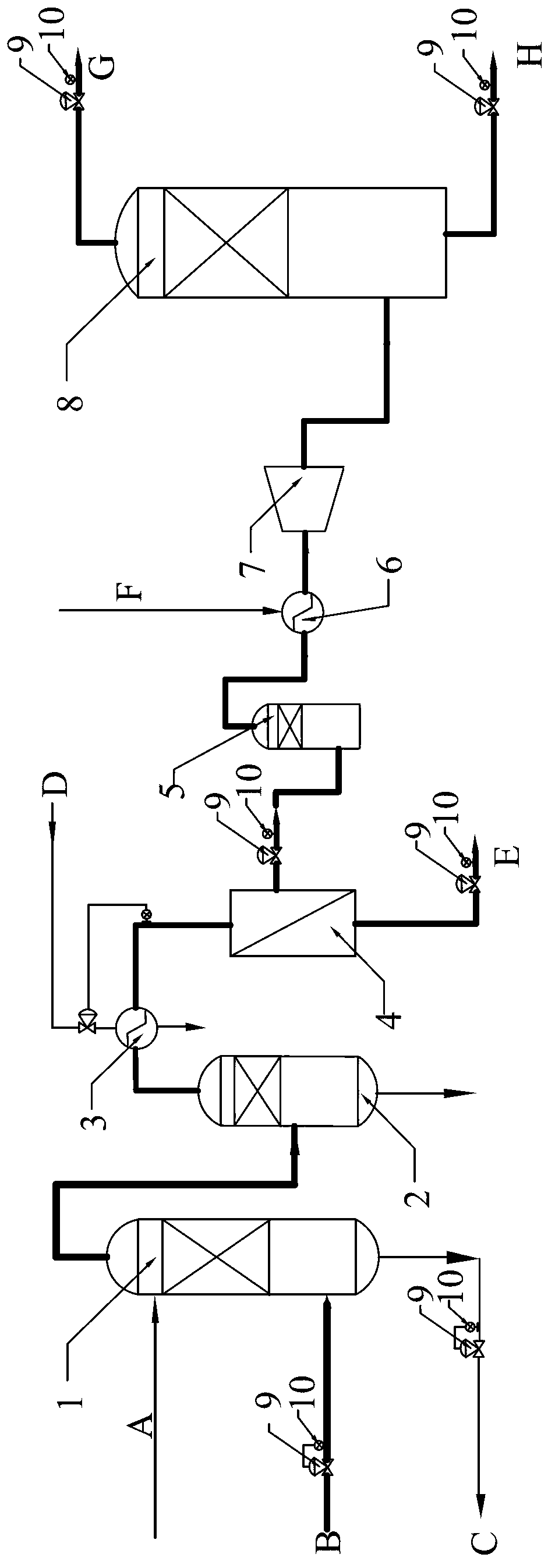

Method and device for recycling hydrogen from synthesis ammonia released air and preparing LNG (liquefied natural gas) with membrane separation and cryogenic integration technology

A technology for synthesizing ammonia and releasing air, which is applied in the field of producing LNG, which can solve the problems of large equipment investment, poor economy, waste of resources, etc., and achieve the effect of less investment, reduced investment, and increased methane content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

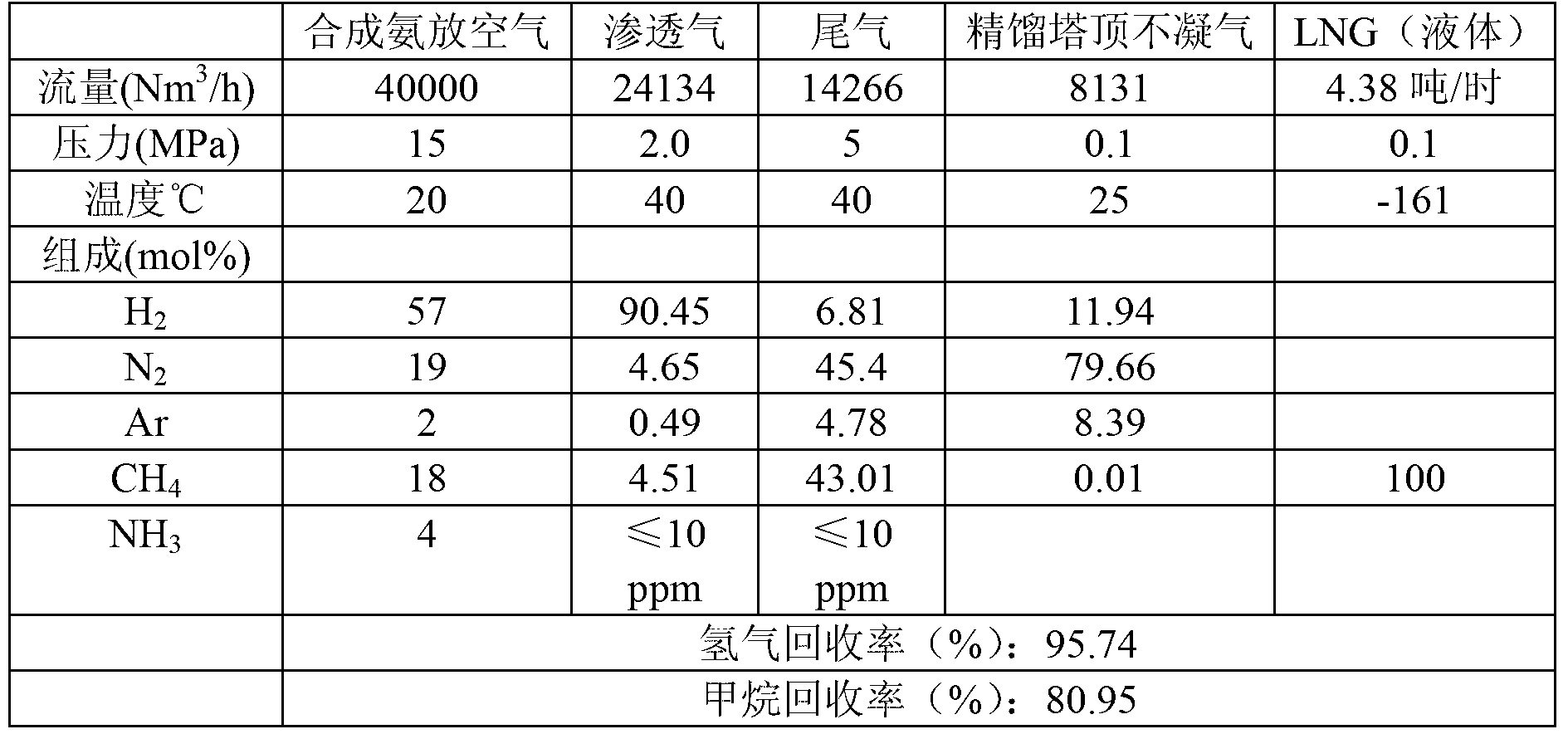

Examples

Embodiment 1

[0040] Synthetic ammonia release air is decompressed to 12.0MPa through the pressure reducing valve, and first enters the ammonia absorption tower 1, and the gas is in countercurrent contact with the pumped desalted water in the high-efficiency packed ammonia absorption tower, and the ammonia in the gas is absorbed by water and becomes ammonia water from discharge from the bottom of the tower. The gas after ammonia washing is discharged from the top of the ammonia absorption tower 1 and then enters the gas-liquid separator 2 to separate the entrained mist generated in the water washing process. Then it enters the sleeve heater 3, and the temperature of the gas heated by the heater 3 generally rises by more than 10°C. In this embodiment, it is selected to be heated to 40°C. There are two purposes of heating, one is to keep the gas away from the water-saturated dew point after washing, and the other is to adjust the working state of the membrane separator 4 . The heated gas is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com