Method for producing charcoal fertilizer

A production method and biochar technology, which are applied in the field of biomass resource utilization, can solve the problems of insufficient fertilizer efficiency of traditional biochar and difficulty in handling human and animal manure, and achieve global climate change improvement, avoid environmental and health problems, and achieve significant economic benefits. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

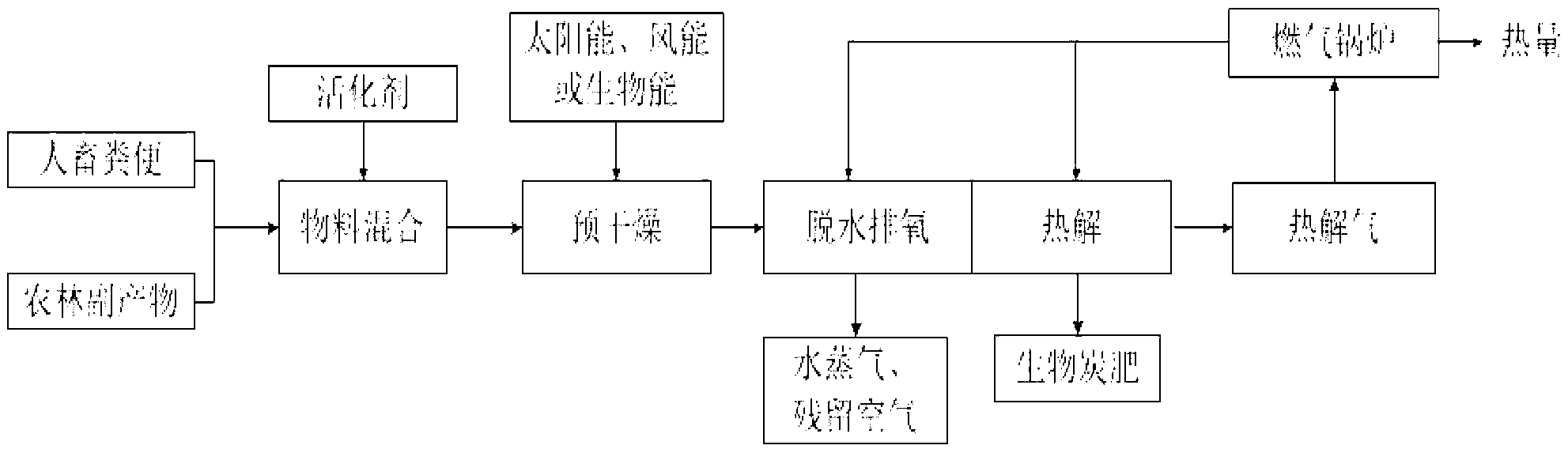

Embodiment approach 1

[0022] Add 1 part of human and animal manure, 3 parts of sawdust and activator according to 10% of the total mass, stir and mix thoroughly to obtain mixture 1; use wind energy and solar energy to reduce the moisture content of mixture 1 to 25%, and obtain mixture 2; mix 2 Put it into the material bin of the carbonization furnace, the filling rate of the material bin is 85%; heat the material bin to 175°C for 25 minutes, during this process, the residual air and water vapor in the material bin are discharged through the exhaust port, and after energy recovery , and the obtained waste liquid is discharged into the sewage treatment system. A small amount of water vapor remains in the material bin. Raise the temperature of the material bin to 450°C at a heating rate of 15°C / min and continue for 1 hour to complete the carbonization of the material. This process will generate a large amount of combustible gas. Before the heating starts, turn the exhaust port valve to the gas boiler...

Embodiment approach 2

[0024] Add 2 parts of human and animal feces, 1 part of wood chips and 5% of the total mass into the activator, stir and mix thoroughly to obtain mixture 3; use wind and solar energy to reduce the moisture content of mixture 1 to 30%, and obtain mixture 4; mix 4 Put it into the material bin of the carbonization furnace, and the filling rate of the material bin is 90%. Heat the material bin to 200°C for 30 minutes. During this process, the residual air and water vapor in the material bin are discharged through the exhaust port. After energy recovery, the obtained waste liquid is discharged into the sewage treatment system. A small amount of water vapor remains in the material bin. Raise the temperature of the material bin to 550°C at a heating rate of 10°C / min and continue for 2 hours to complete the carbonization of the material. This process will generate a large amount of combustible gas. Before the heating starts, turn the exhaust port valve to the gas boiler, and the ener...

Embodiment approach 3

[0026] Add 1 part of human and animal manure, 1 part of sawdust and activator according to 5% of the total mass, stir and mix thoroughly to obtain mixture 5; use wind and solar energy to reduce the moisture content of mixture 1 to 20%, and obtain mixture 6; mix 6 Put it into the material bin of the carbonization furnace, and the filling rate of the material bin is 90%. Heat the material bin to 150°C for 30 minutes. During this process, the residual air and water vapor in the material bin are discharged through the exhaust port. After energy recovery, the obtained waste liquid is discharged into the sewage treatment system. A small amount of water vapor remains in the material bin. Raise the temperature of the material bin to 450°C at a heating rate of 25°C / min and continue for 1.5 hours to complete the carbonization of the material. This process will generate a large amount of combustible gas. Before the heating starts, turn the exhaust port valve to the gas boiler, and the e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com