Post-unfreezing water burst prevention method of non-full-depth freezing vertical shaft

A non-full-depth, freezing method, which is applied in wellbore lining, shaft equipment, earthwork drilling and production, etc., can solve problems such as poor timing of grouting, failure to achieve grouting effect, and poor grouting effect. It achieves the effects of significant water prevention and control, convenient construction and operation, and strong impermeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

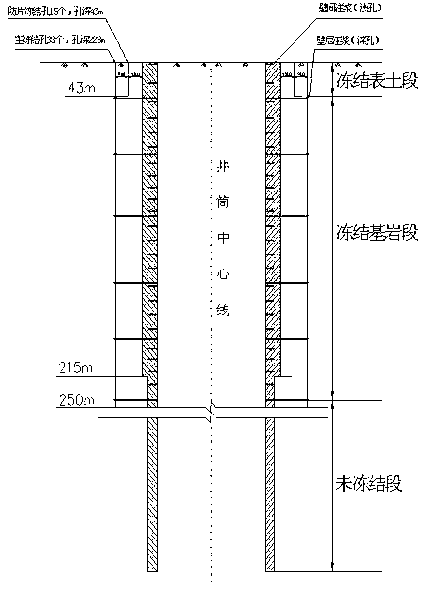

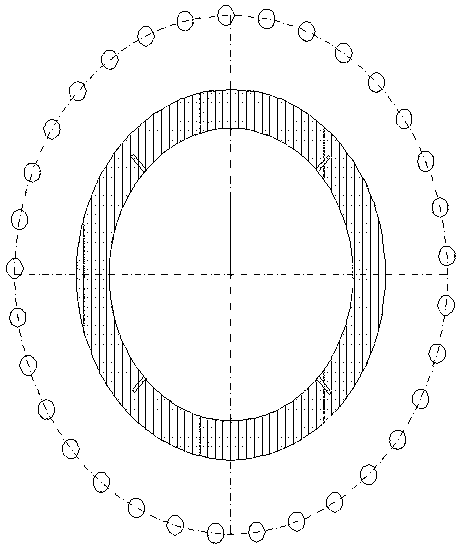

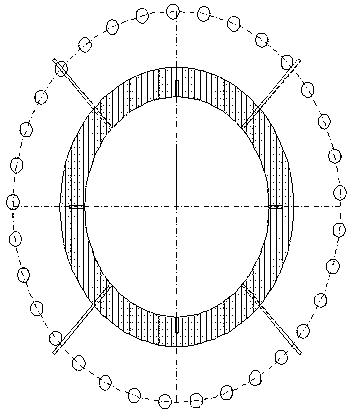

[0042] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 Shown, a kind of non-full deep-frozen vertical well thaws the water inrush prevention method after thawing, and this method is carried out according to the following steps:

[0043] 1) Determination of grouting form

[0044] After the wellbore is thawed, the fissures in the surrounding rocks are connected, and the water gushing out from the fissures in the surrounding rocks is relatively large. In areas with rich water and weak seepage, the general grouting form is difficult to inject or the injection effect is not good. Combined use of high and low pressure, deep and shallow holes combined grouting method;

[0045] 2) Determination of the timing of wellbore water prevention and control:

[0046] (1) In order to ensure the safe construction of the lower shaft and the horse head gate in the construction of the unfrozen section, during the construction of the lower shaft and the horse head door, the up...

Embodiment 2

[0072] Main well grouting scheme

[0073] (1) Fabrication and layout of grouting pipes

[0074] The grouting hole uses YT-28 wind hammer, together with 42mm "one"-shaped drill bit drills holes, the hole depth passes through the well wall and enters the surrounding rock 1000mm, six holes are arranged on each level and grouting pipes are installed, and the upper and lower horizontal holes should be staggered. Note Slurry pipe adopts Made of 32㎜ seamless steel pipe, one end is equipped with a horse tooth buckle, and the other end is equipped with an inner threaded buckle piping cap. The length is processed according to the wall thickness. The grouting pipe is wound with hemp silk and driven into the hole. The exposed length shall not exceed 50mm.

[0075] (2) Configuration of slurry

[0076] The grouting uses two types of single liquid cement slurry and cement water glass double liquid slurry. Its application principle is based on single-liquid slurry, supplemented by doubl...

Embodiment 3

[0094] Auxiliary Well Grouting Scheme

[0095] (1) drilling

[0096] The grouting hole construction uses the YTP-26 air leg rock drill mm drill bit and hollow hexagonal steel drill to drill holes, and special pipe burying device to bury pipes.

[0097] The position of the grouting hole behind the wall of the bedrock section is determined according to the actual position of the water outlet point. Generally, the holes are arranged within 1m of the water outlet point. Before construction, experienced veteran workers carry out on-site positioning. The hole depth is preferably 0.5m through the wall of the bedrock section and into the rock. The specification of the grouting pipe is φ38×600mm.

[0098] The interwall grouting is carried out in layers. Starting from the vertical depth -234m, the horizontal filling grouting holes with a distance between layers of 50m are evenly arranged in the four directions of the well wall, and the pipe is buried in the way of casing. First use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com