Method for rapidly monitoring solubility of beer wheat malt protein

A protein and wheat germ technology, applied in the measurement of color/spectral characteristics, can solve the problems of high cost, complicated operation, and many steps, and achieve the effect of improving product quality and economic benefits, and improving processing efficiency and quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

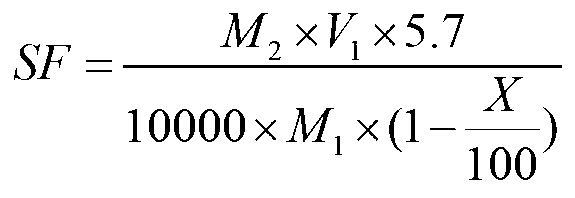

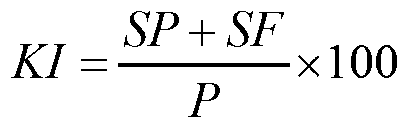

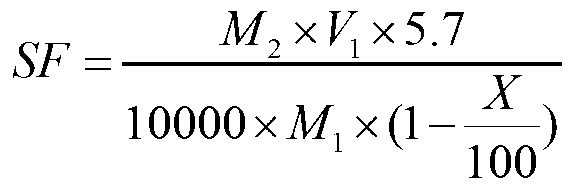

Image

Examples

preparation example Construction

[0037] (1) Preparation of standard curve

[0038] With bovine serum albumin as the standard protein, prepare 2mg / mL bovine serum albumin aqueous solution. Follow the steps below to make a standard curve: take 10 sets of colorimetric tubes, number them, add reagents according to Table 1.1, shake well and let stand at room temperature for 30 minutes, then measure color at 540nm. Draw the standard curve with the protein content (mg) as the abscissa and the absorbance as the ordinate (Table 1.2). The standard curve equation of protein content x (mg) and absorbance value y is y=0.0634x+0.006 (r 2 =0.9995).

[0039] Table 1.1 Standard curve reagent addition table

[0040]

[0041] Table 1.2 Standard curve data

[0042]

[0043] (2) Sample determination

[0044] take S 水溶 Add 0.4mL to a 25mL colorimetric tube, add 1.6mL water, 3mL biuret reagent, shake well and let stand at room temperature for 30min, then measure color at 540nm. The blank is 2mL of distilled water, add ...

Embodiment 1

[0055] A malting experiment was carried out with Yan 24 wheat as raw material.

[0056] 1. Determination of protein content in raw wheat

[0057] The dry basis percentage of protein in Yan 24 raw wheat was P=12.55%.

[0058] 2. Sampling

[0059] From the first day of germination, sampling is carried out once a day for 6 consecutive days, and 75g of uniform and representative green malt samples are taken each time, and the sample S to be tested is obtained by grinding. 1 ~S 6 .

[0060] 3. Determination of moisture content of green malt

[0061] Refer to the "Beer Malt" (QB / T1686) standard to determine the sample S to be tested 样 Medium moisture content X (%), see Table 1.3 for specific values.

[0062] Table 1.3 Moisture content in green malt

[0063]

[0064] 4. Extraction of water-soluble protein from green malt

[0065] Accurately weigh 8g of green malt sample M 1 (see Table 1.4 for data), put in a 50mL centrifuge tube, add 15g of distilled water, shake and extr...

Embodiment 2

[0088] A malting experiment was carried out with tobacco 5158 wheat as raw material.

[0089] 1. Determination of protein content in raw wheat

[0090] Dry basis protein content in raw wheat of Yan 5158 P=14.32%

[0091] 2. Sampling

[0092] From the first day of germination, sample 1 time a day, take a uniform and representative green malt sample 65g each time, and grind it to obtain the sample S to be tested 1 ~S 6 .

[0093] 3. Determination of moisture content of green malt

[0094] Refer to the "Beer Malt" (QB / T1686) standard to determine the sample S to be tested 样 Medium moisture content X (%), see Table 1.9 for specific values.

[0095] Table 1.9 Moisture content in green malt

[0096]

[0097] 4. Extraction of water-soluble protein from green malt

[0098] Accurately weigh 7-8g green malt sample M 1 (see Table 1.10 for data), put in a 50mL centrifuge tube, add 15mL of distilled water, shake and extract at 250r / min for 15min, centrifuge at 4000r / min for 5mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com