Pit embedded circuit board three-dimensional assembling method

A technology of circuit substrate and assembly method, which is applied in the field of board-level three-dimensional assembly structure of electronic devices, can solve the problems of difficult assembly and difficult to guarantee the timing of signal transmission, etc., and achieve the goal of saving space, improving three-dimensional assembly density, and realizing miniaturization Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

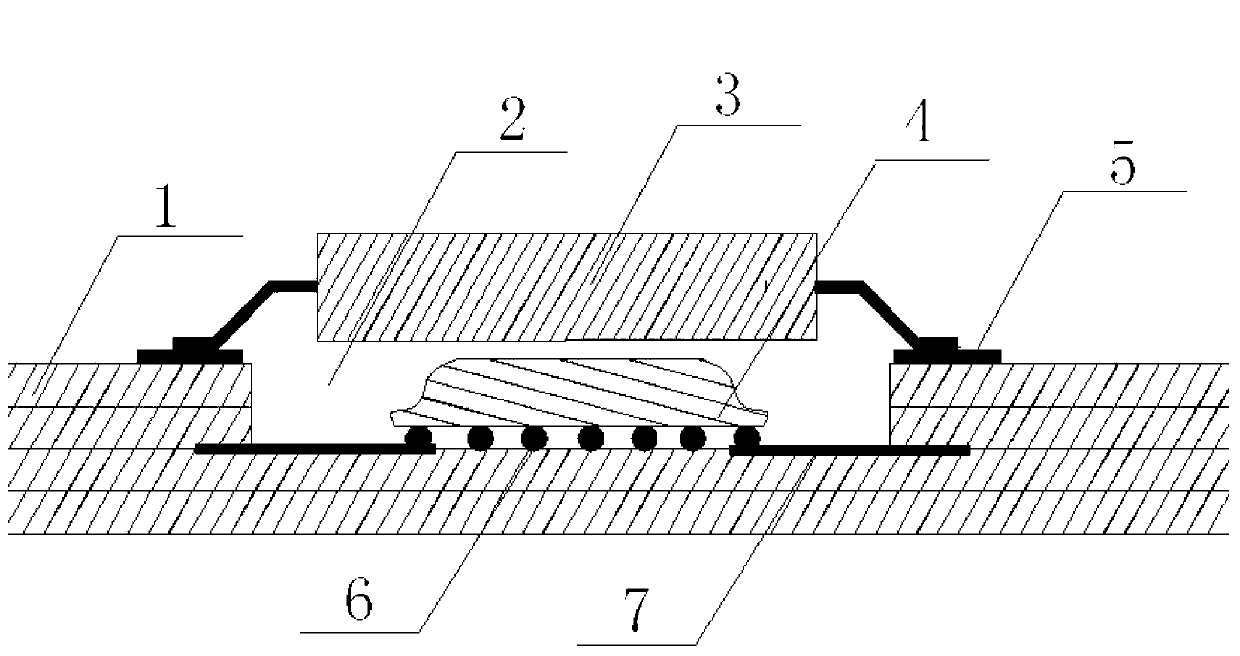

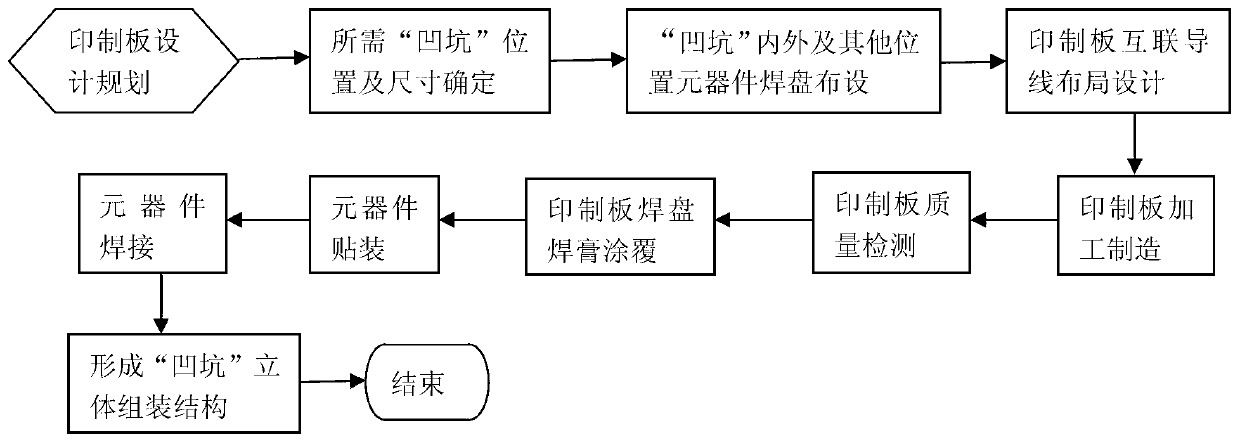

[0018] refer to figure 1 . According to the present invention, in a preferred embodiment described below, the cavity-embedded circuit substrate three-dimensional assembly structure first plans, designs and manufactures the sunken cavity 2 for assembling components on the printed board. During the manufacturing process of the printed board 1 , the depressed pits 2 are formed by controlling the shape of each layer of the printed board 1 . Then, according to the circuit principle design, the wiring design in the printed board 1 is carried out to complete the layout of the electrical signal transmission channels between the devices; a suitable jumper device 3 is arranged directly above the assembled device 4 in the sunken pit 2, for example, on the printed board 1 The layout above the sunken pit 2 is designed for devices with surrounding leads such as plastic-encapsulated lead chip carrier PLCC, square flat no-lead package QFN, and the like. Layout the selected thin and small c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com