Compositions for etching metal layers

A composition and metal film technology, applied in the field of metal films, can solve the problems of etching device deposition problems, etc., and achieve the effects of excellent etching morphology, reduction of defect ratio, and reduction of foreign matter formation and deposition.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

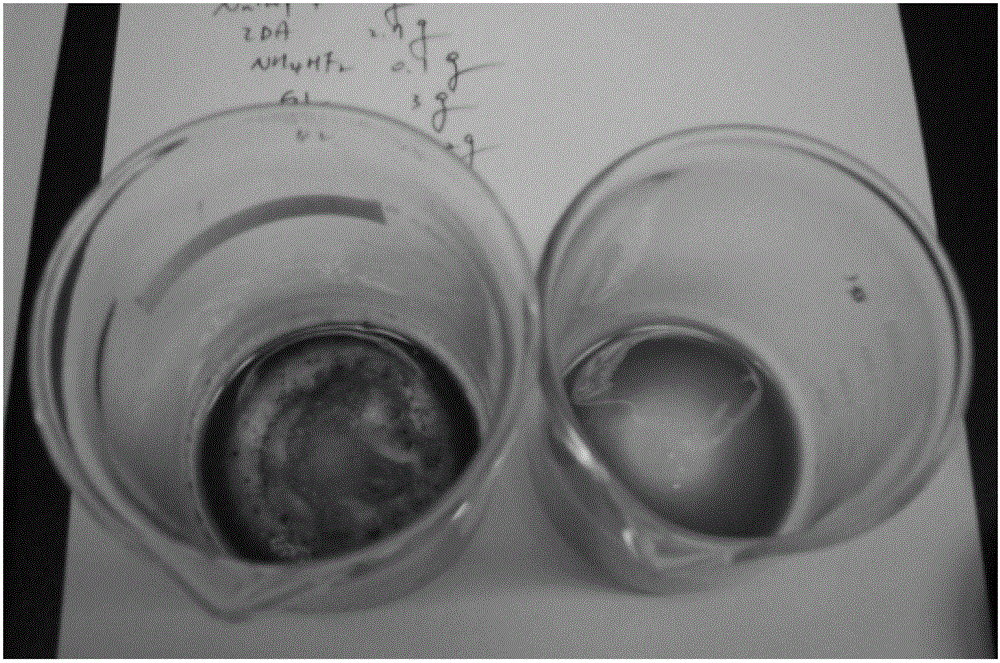

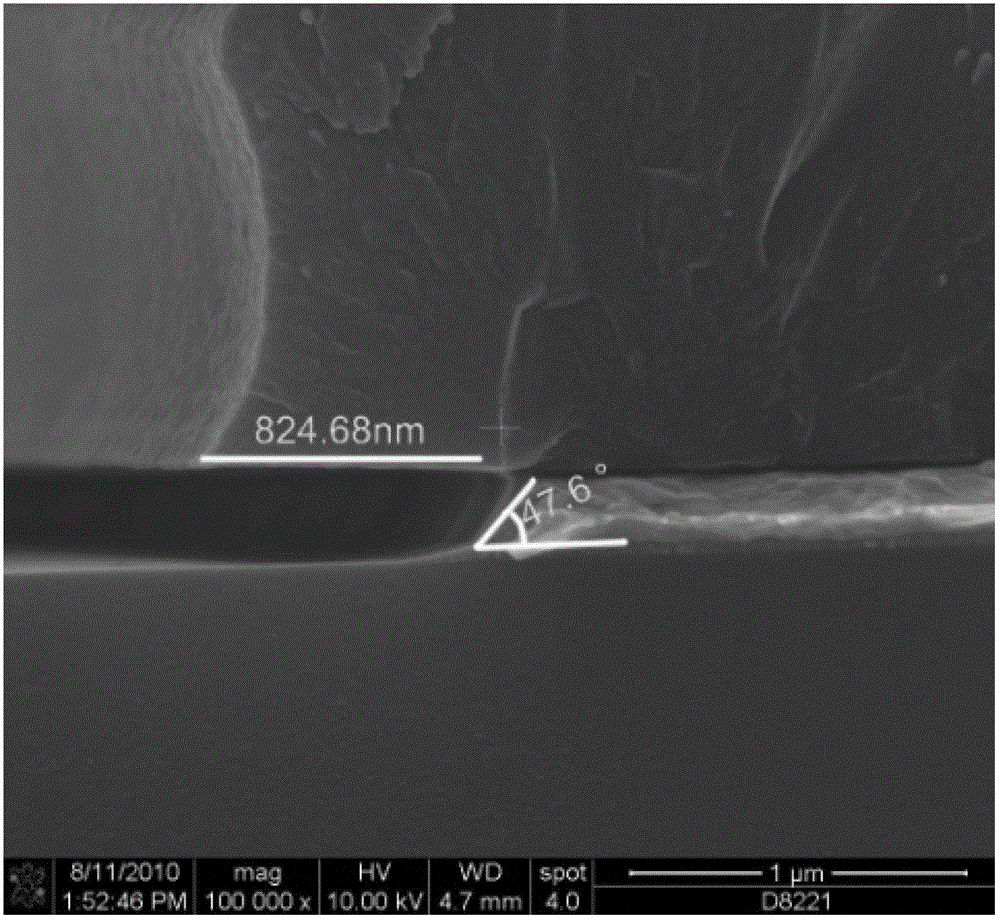

Image

Examples

Embodiment 1-18 and comparative example 1-2

[0040] A composition for etching including an oxidizing agent, an etching control agent, a chelating agent, an undercutting inhibitor, a copper etching inhibitor, a residue remover and water is prepared. Details on the components and composition are given in Table 1.

[0041] Table 1

[0042]

[0043]

[0044] Evaluation of etching performance

[0045] In order to test the performance of the etchant composition according to the present invention, a copper / molybdenum-titanium alloy double-layer substrate was prepared. The molybdenum-titanium alloy has a 1:1 weight ratio. The copper and molybdenum-titanium alloy are deposited on the substrate by sputtering as in the LCD glass substrate manufacturing process. The copper layer and the molybdenum-titanium alloy layer are deposited in two different thicknesses. The thickness is respectively copper / Mo-Ti And copper Molybdenum-titanium

[0046] Each etchant in Examples 1-18 and Comparative Examples 1-2 was heated in a spray wet etchi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com