Preparation method of solvent-resistant compound nanofiltration membrane

A composite nanofiltration membrane and solvent-resistant technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of low solvent permeation flux, good compatibility of alcohol solvents, etc., and achieve excellent stability properties, increase anti-pollution properties, and increase the effect of binding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0018] Specific embodiment one: This embodiment is a preparation method of a solvent-resistant composite nanofiltration membrane, specifically prepared according to the following steps:

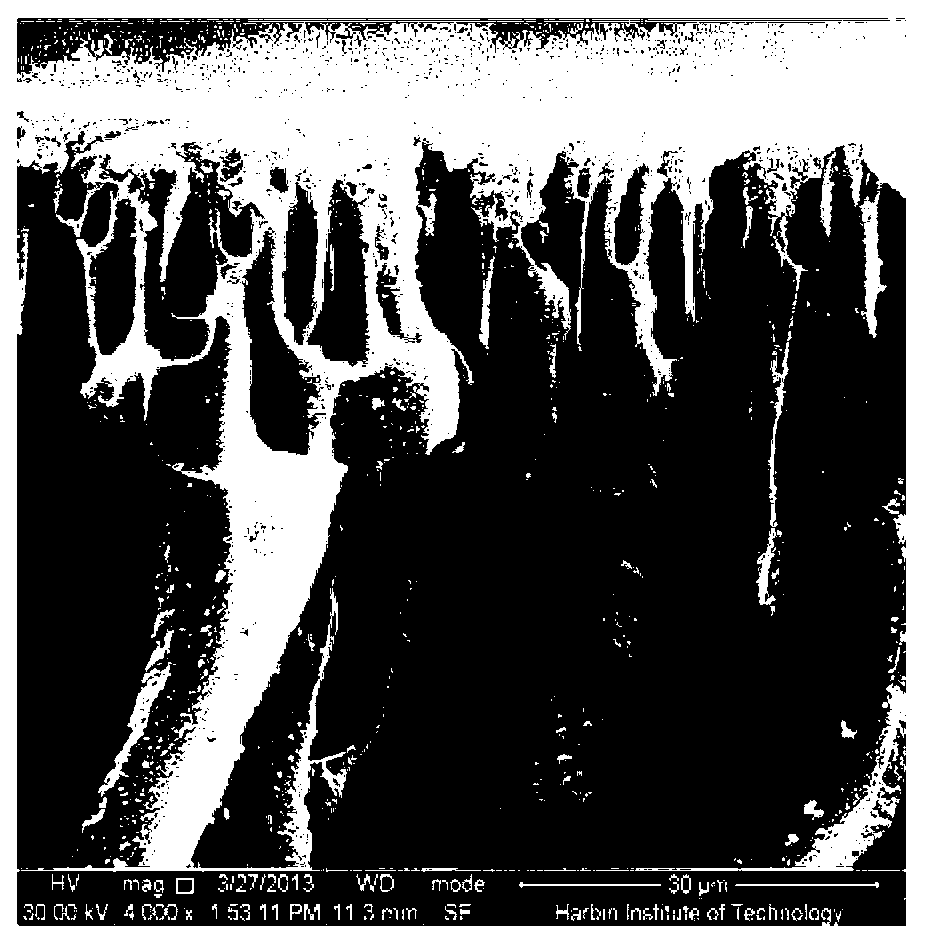

[0019] 1. Preparation of ultrafiltration base membrane: First, dissolve the polymer in a solvent to prepare a polymer solution with a mass fraction of 18% to 25%, and then use the immersion-precipitation method to dissolve the polymer with a mass fraction of 18% to 25%. The solution is made into an ultrafiltration basement membrane;

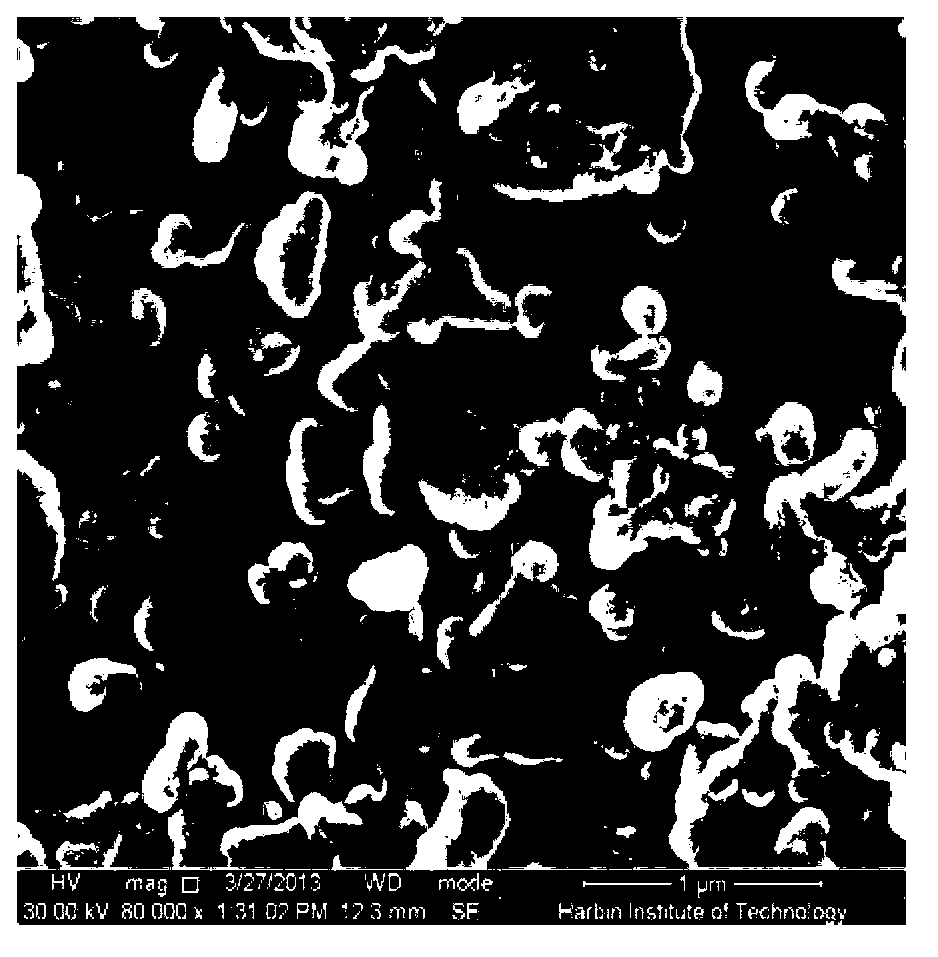

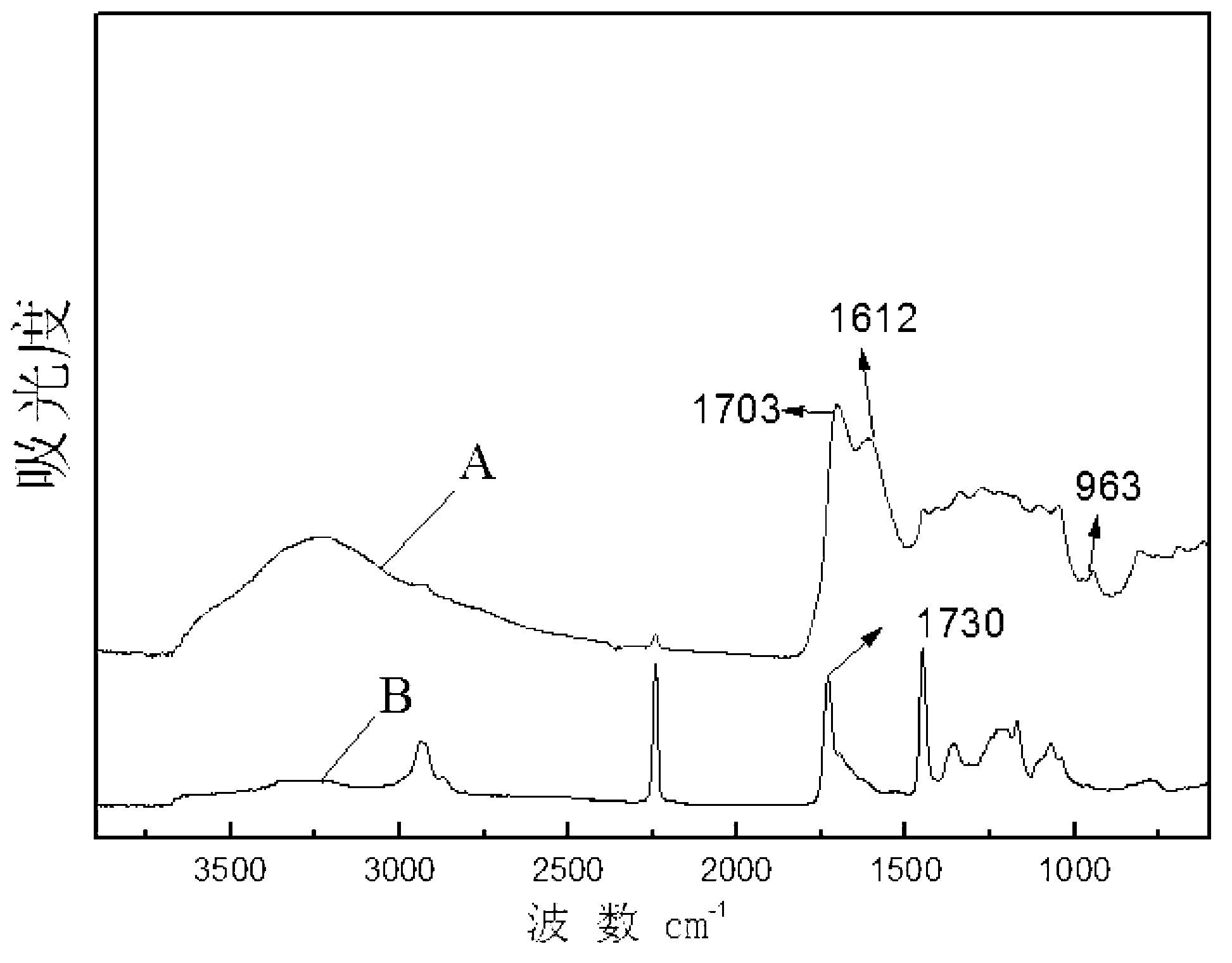

[0020] 2. Preparation of pyrrole-ethanol / graphene oxide solution: first, graphene oxide is ultrasonically dispersed in ethanol, then pyrrole is added, and after mixing, pyrrole-ethanol / graphene oxide solution is obtained; described pyrrole-ethanol / graphene oxide solution The mass fraction of pyrrole is 0.5% to 20%; the mass fraction of graphene oxide in the pyrrole-ethanol / graphene oxide solution is 0.01% to 0.5%;

[0021] 3. Configure strong oxidant solution: ...

specific Embodiment approach 2

[0028] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the polymer described in Step 1 is polyetherimide, polysulfone, polyethersulfone, polyacrylonitrile or polytetrafluoroethylene. Others are the same as the first embodiment.

specific Embodiment approach 3

[0029] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that the solvent described in step 1 is N-methylpyrrolidone, dimethylformamide, dimethylacetamide or dimethyl sulfoxide. Others are the same as those in Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com