Process for preparing graphene oxides

A technology of graphene and graphite, which is applied in the field of graphene oxide preparation, can solve the problems of prolonging the production cycle, reducing the utilization rate of equipment, and difficulty in recycling waste liquid, so as to improve the utilization rate of materials, increase the utilization rate of equipment, and facilitate separation and purification Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

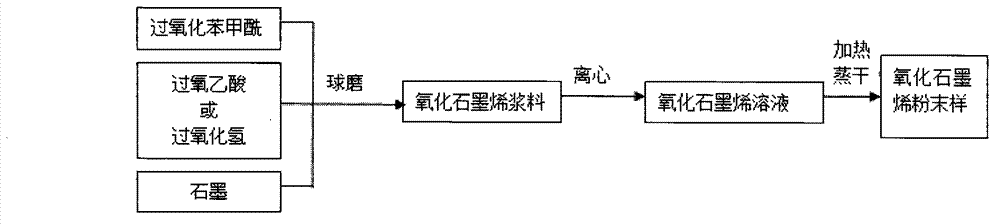

[0026] After mixing 2g reagent graphite powder and 2g benzoyl peroxide, add 15g concentration of 30% peracetic acid / hydrogen peroxide solution, and vibrate ball mill for 1h under the conditions of stainless steel ball mill jar and stainless steel ball, to obtain graphite oxide Then, the obtained graphene oxide slurry was configured as 200ml aqueous solution, and after standing for clarification, the supernatant liquid was taken, and the supernatant liquid was heated and evaporated to dryness to obtain a graphene oxide powder sample. After determination, the yield of the obtained graphene oxide was 22.92%.

Embodiment 2

[0028] On the basis of Example 1, keeping other conditions unchanged, just changing graphite into expanded graphite, the yield of graphene oxide finally obtained was 28.44%.

Embodiment 3

[0030] 2g reagent graphite powder, 6g benzoyl peroxide, and 15g concentration are 30% peracetic acid / hydrogen peroxide solution in a stainless steel ball mill jar and a stainless steel ball for 1 h to obtain a graphene oxide slurry, and then The obtained graphene oxide slurry was configured as a 200ml aqueous solution and allowed to stand for clarification, then the supernatant was taken, and the supernatant was heated and evaporated to dryness to obtain a graphene oxide powder sample.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com