Process and device for electric cracking catalytic oxidation and electric flocculation for petroleum drilling wastewater

A technology of catalytic oxidation and oil drilling, applied in mining wastewater treatment, oxidized water/sewage treatment, water/sewage treatment, etc., can solve problems such as insufficient oxygen content, incomplete redox reaction, difficulty in achieving ideal quality, etc., to achieve Increase the utilization rate of electric energy, solve the effect of electrode consumption and high current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

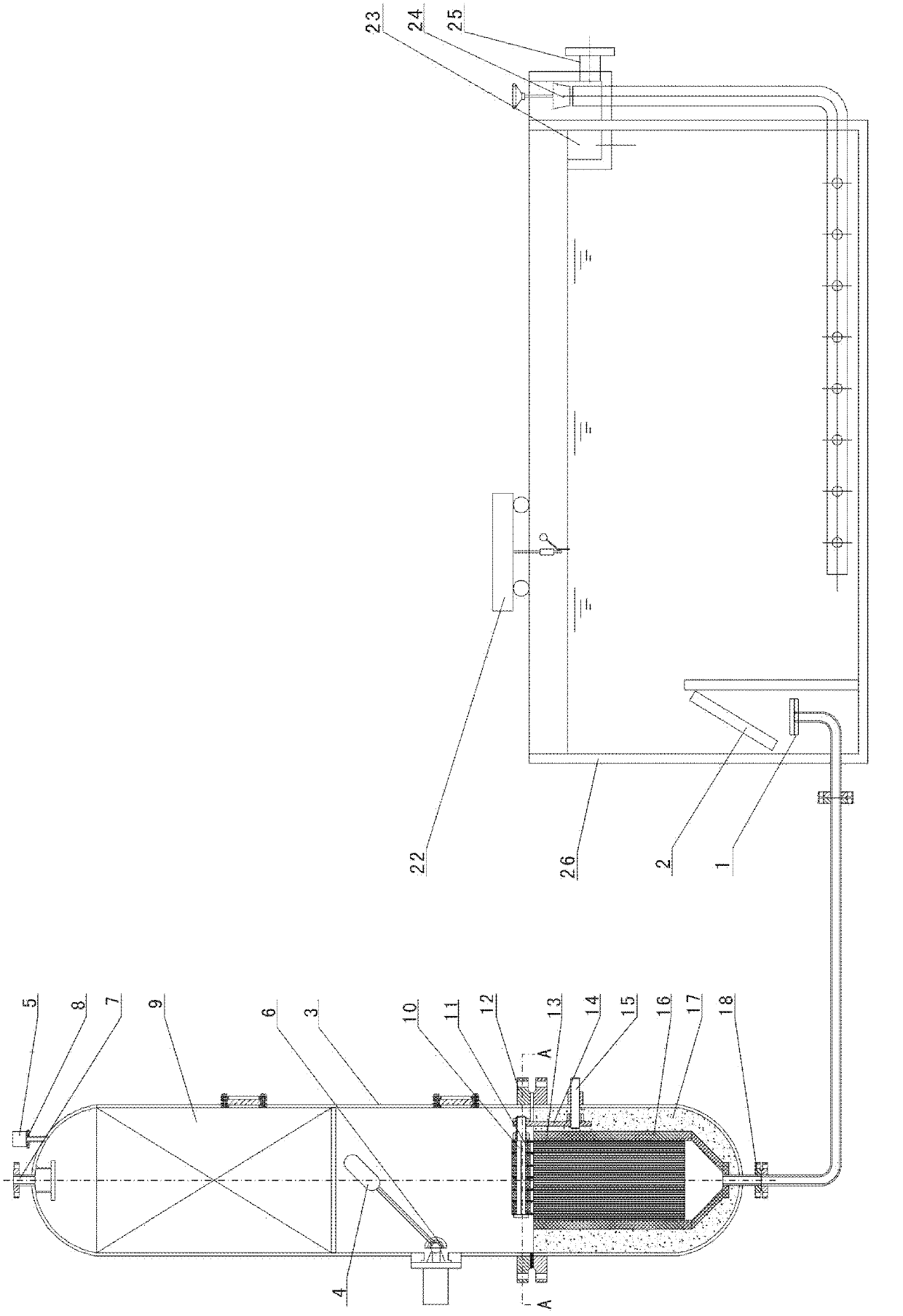

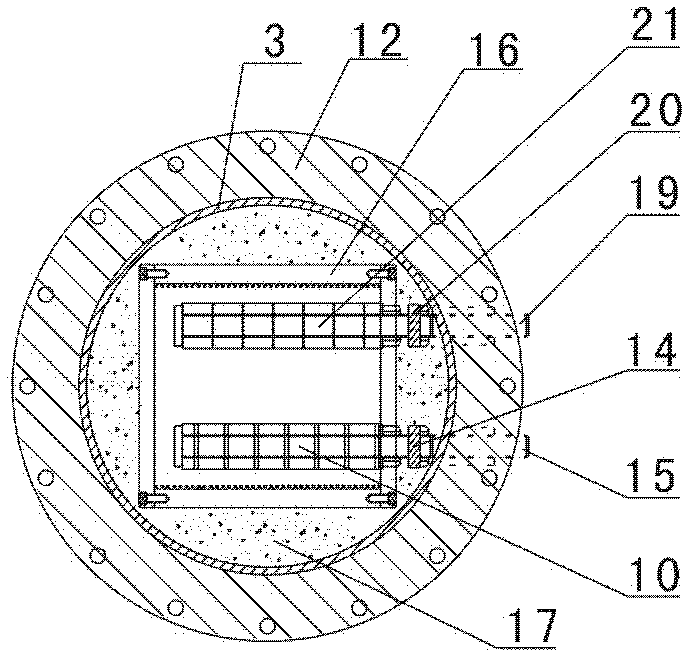

[0034] Below in conjunction with accompanying drawing, the present invention is described in further detail:

[0035] Such as figure 1 As shown, the electrolysis catalytic oxidation and electroflocculation process of petroleum drilling wastewater according to the present invention includes an electrolysis catalytic redox process and an electroflocculation process, and the electrolysis catalytic redox process is before the electroflocculation process; the electrolysis catalytic redox process is in one Carry out in the high-pressure sealed reaction tank 3, the pressure in the sealed reaction tank 3 is 0.2-0.5Mpa. In the electrolysis catalytic redox process, the pressure in the sealed reaction tank 3 is realized by delivering high-pressure air to the sealed reaction tank 3 through an air compressor (not shown in the figure); the electrode plate 13 adopts a titanium-based coating plate, and the electrode plate 13 The current density is 3000-4000A / m 2 ; The inner upper space of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com