Reddish-black jun porcelain glaze prepared by utilizing metal copper and iron and preparation method of reddish-black jun porcelain glaze

A technology of metallic copper and Jun porcelain is applied in the field of sky blue Jun porcelain glaze and its preparation, and the preparation field of Jun porcelain glaze can solve the problems of non-compliance with energy saving and emission reduction, high cost and high energy consumption, and achieves easy control of firing atmosphere and easy firing. The effect of wide temperature range, energy consumption and pollution reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

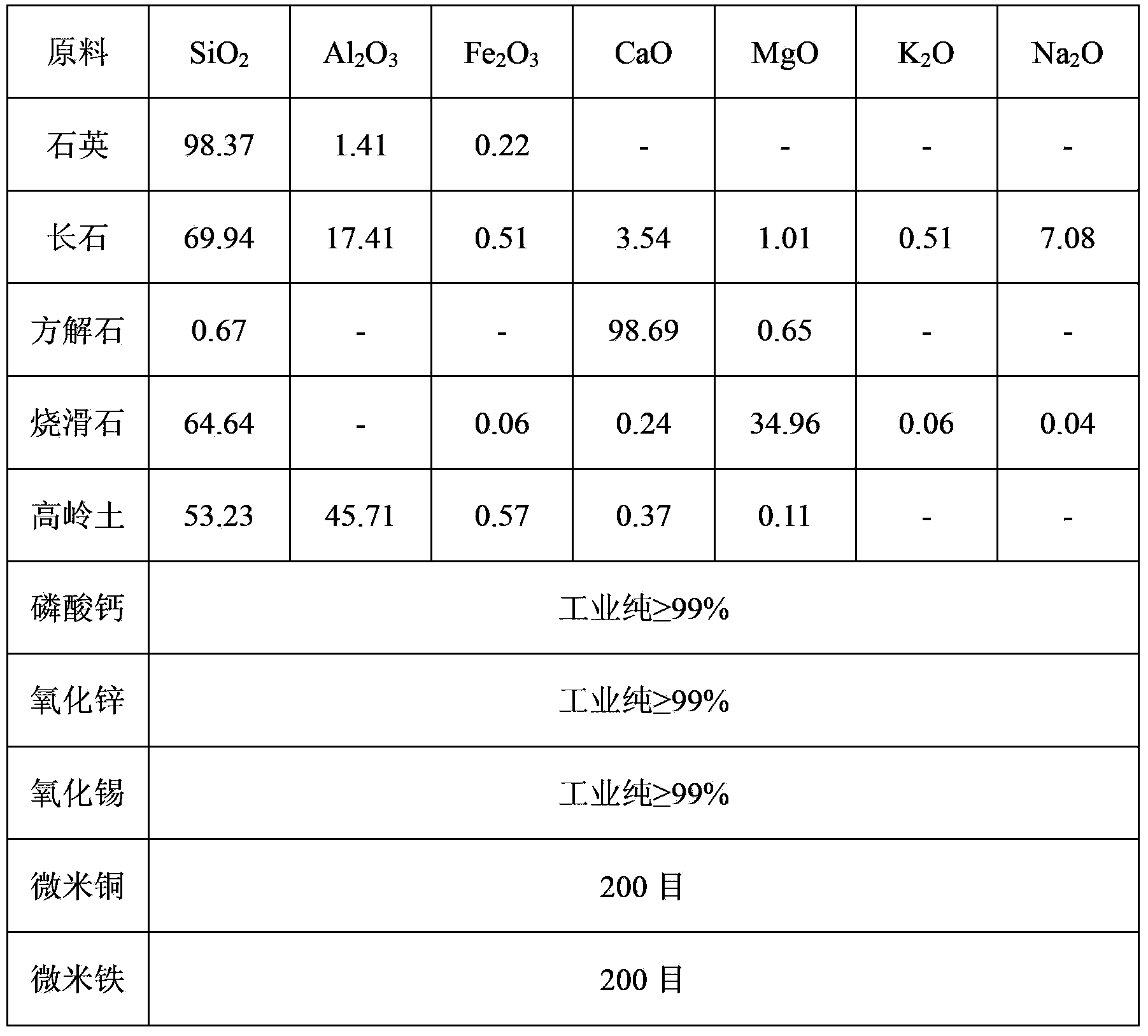

[0025] The method for preparing Tianqing Jun enamel by using metallic copper and iron comprises the following steps:

[0026] 1) By mass percentage, mix 50% feldspar, 20% quartz, 17% calcite, 7% talc, 3% calcium phosphate, and 3% kaolin to obtain a mixture, and then add the mixture to the total Mass 0.5% ZnO, 2% SnO 2 , 1% Fe, 0.5% Cu, 0.3% cellulose and 1% sodium tripolyphosphate, fully mixed to obtain a mixed glaze;

[0027] 2) Press to mix the glaze: ball: water = 1:2:0.8 mass ratio, put the mixture, ball and water into the ball mill for wet ball milling, finely grind for 30 minutes to 250 mesh, get the glaze slurry, adjust the glaze The specific gravity of pulp is 1.65g / cm 3 ;

[0028] 3) Apply the glaze slurry evenly on the biscuit body, after drying, fire it in a box-type resistance furnace with a neutral or weak oxidizing atmosphere at 1280°C, keep it warm for 20 minutes, and cool it with the furnace to obtain Tianqing Jun enamel.

Embodiment 2

[0030] The method for preparing Tianqing Jun enamel by using metallic copper and iron comprises the following steps:

[0031] 1) By mass percentage, mix 50% feldspar, 25% quartz, 14% calcite, 5% talc, 2.9% calcium phosphate, and 3.1% kaolin to obtain a mixture, and then add the mixture to the total Mass 0.9% ZnO, 1.5% SnO 2 , 2% Fe, 1.5% Cu, 0.3% cellulose and 1% sodium tripolyphosphate, fully mixed to obtain a mixed glaze;

[0032] 2) Press to mix the glaze: ball: water = 1:2:0.8 mass ratio, put the mixture, ball and water into the ball mill for wet ball milling, finely grind for 30 minutes to 250 mesh, get the glaze slurry, adjust the glaze The specific gravity of pulp is 1.57g / cm 3 ;

[0033] 3) Apply the glaze slurry evenly on the biscuit body, after drying, fire it in a box-type resistance furnace with a neutral or weak oxidizing atmosphere at 1260 ° C, keep it warm for 30 minutes, and then cool it with the furnace to obtain Tianqing Jun enamel.

Embodiment 3

[0035] The method for preparing Tianqing Jun enamel by using metallic copper and iron comprises the following steps:

[0036] 1) By mass percentage, mix 45% feldspar, 30% quartz, 14% calcite, 5% talc, 3.5% calcium phosphate, and 2.5% kaolin to obtain a mixture, and then add the mixture to the total 1.5% ZnO by mass, 2.5% SnO 2 , 0.2% Fe, 0.1% Cu, 0.1% cellulose and 0.5% sodium tripolyphosphate, fully mixed to obtain a mixed glaze;

[0037] 2) Press to mix the glaze: ball: water = 1:2:0.8 mass ratio, put the mixture, ball and water into the ball mill for wet ball milling, finely grind for 35 minutes to 250 mesh, get the glaze slurry, adjust the glaze The specific gravity of pulp is 1.67g / cm 3 ;

[0038] 3) Apply the glaze slurry evenly on the biscuit, and after drying, fire it in a box-type resistance furnace at 1300°C with a neutral or weakly oxidizing atmosphere, keep it warm for 20 minutes, and then cool it with the furnace to obtain Tianqing Jun enamel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com