A kind of high dielectric composite material, its preparation method and application

A composite material and high dielectric technology, applied in the field of nanocomposite materials, can solve problems such as brittleness and poor mechanical properties, and achieve the effects of improving interfacial compatibility, facilitating formation and transfer, and improving dispersibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

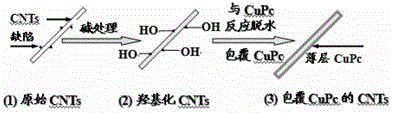

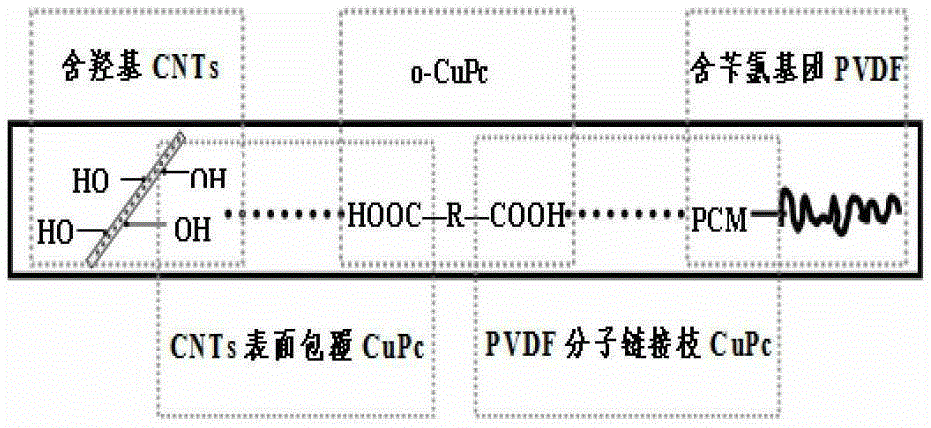

Method used

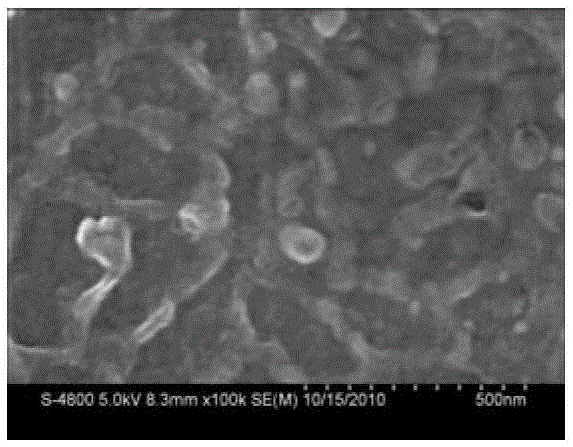

Image

Examples

Embodiment 1

[0041] 1. Preparation of high dielectric composite materials:

[0042] (1) Add 5g of PVDF into a three-necked bottle containing 20ml of NMP, stir until completely dissolved, put the three-necked bottle in an oil bath at 25°C, add 5gp-CMS, and pass N 2 , put the reaction bottle in a 60°C oil bath for 10h, pour the solution into 200ml of dichloromethane to precipitate and centrifuge, and dry it at a vacuum of 80KPa and a temperature of 90°C to obtain active benzyl chloride on the molecular chain group of PVDF; 30mlDMF was added to a 100ml spherical condenser with a magnetic stirrer, slowly added 3g of the resulting product and 1go-CuPc, stirred to dissolve the solid completely, and 2 Add 1.5ml triethylamine to the atmosphere, stir at 60°C for 20h and stop heating; pour the solution into 300ml distilled water to precipitate the product, and dry it in vacuum to obtain PVDF with o-CuPc grafted on the molecular chain;

[0043] (2) Place 1.5g of CNTs in 40ml of 30% KOH aqueous solut...

Embodiment 2

[0049] 1. Preparation of high dielectric composite materials:

[0050] (1) Add 3.5g of PVDF into a three-necked flask containing 30ml of NMP, stir until completely dissolved, put the three-necked flask in an oil bath at 25°C, add 3.5gp-CMS, vacuumize and pass through N 2 , put the reaction bottle in an 80°C oil bath for 5 hours, pour the solution into 350ml of dichloromethane to precipitate and centrifuge, and dry it at a vacuum of 80KPa and a temperature of 80°C to obtain active benzyl chloride on the molecular chain group of PVDF; 30mlDMF was added to a 100ml spherical condenser with a magnetic stirrer, slowly added 3g of the resulting product and 1go-CuPc, stirred to dissolve the solid completely, and 2 Add 0.5ml triethylamine to the atmosphere, stir at 80°C for 10h and stop heating. The solution was poured into 450 ml of distilled water to precipitate the product, and dried in vacuum to obtain PVDF with o-CuPc grafted on the molecular chain.

[0051] (2) Place 1g of CNTs...

Embodiment 3

[0057] 1. Preparation of high dielectric composite materials:

[0058] (1) Add 4gPVDF into a three-necked bottle containing 40ml of NMP, stir until completely dissolved, put the three-necked bottle in an oil bath at 25°C, add 4gp-CMS, vacuumize and pass N 2 , put the reaction bottle into a 70°C oil bath for 8 hours, pour the solution into 600ml of dichloromethane to precipitate and centrifuge, and dry it at a vacuum of 80KPa and a temperature of 100°C to obtain active benzyl chloride on the molecular chain group of PVDF; 40mlDMF was added to a 100ml spherical condenser with a magnetic stirrer, slowly added 3g of the resulting product and 1go-CuPc, stirred to dissolve the solid completely, and 2 Add 1ml of triethylamine to the atmosphere, stir at 70°C for 15h and stop heating; pour the solution into 500ml of distilled water to precipitate the product, and dry it in vacuum to obtain PVDF with o-CuPc grafted on the molecular chain;

[0059] (2) Place 1g of CNTs in 50ml of 30% Na...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com