High-thermal-conductivity thermosetting resin and preparation method thereof

A thermosetting, high thermal conductivity technology, applied in the chemical industry, can solve the problems of sacrificing thermosetting resin molding manufacturability, limiting applications, etc., to achieve the effect of reducing effective paths, good optical properties, and reducing filling volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

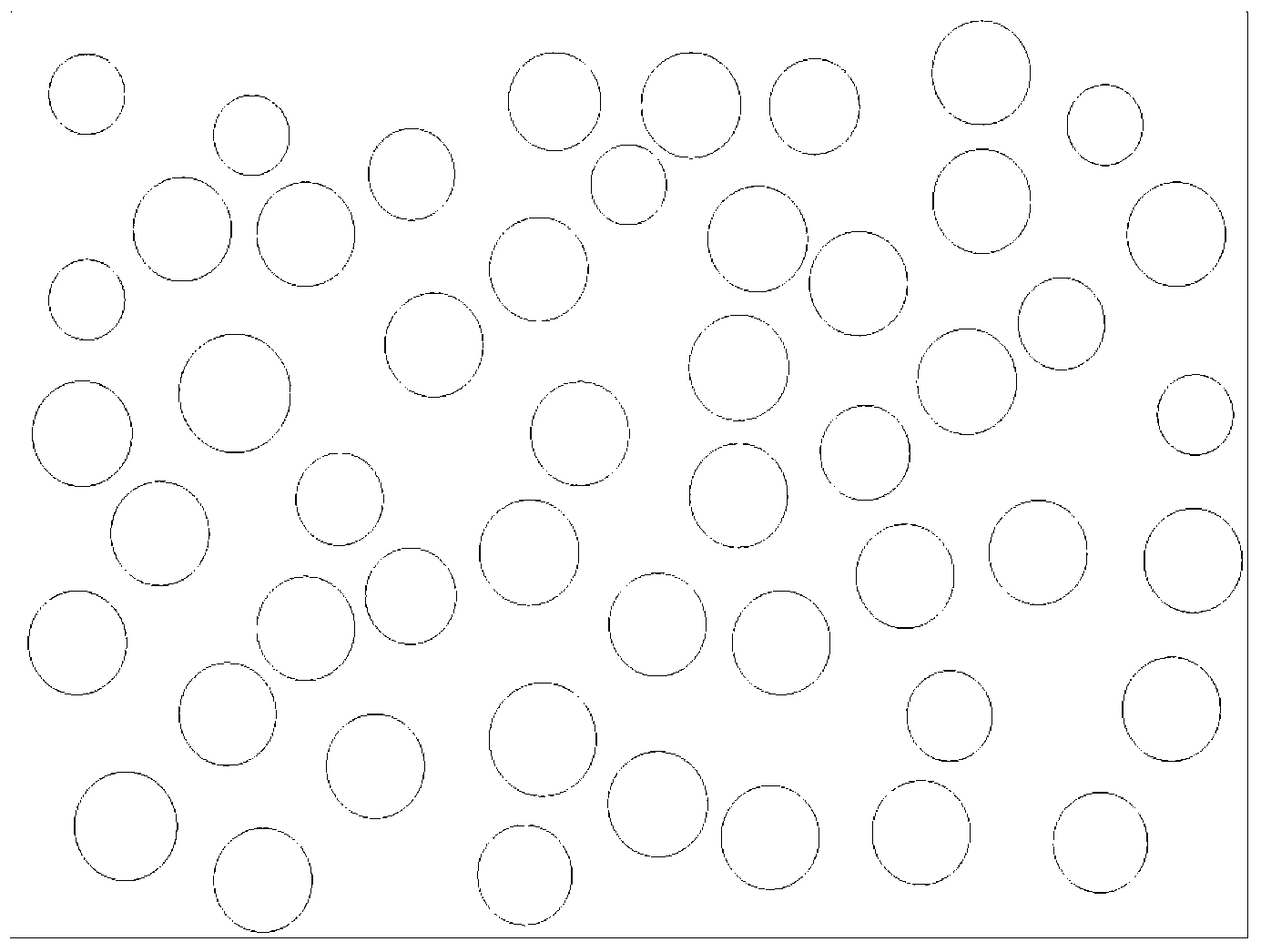

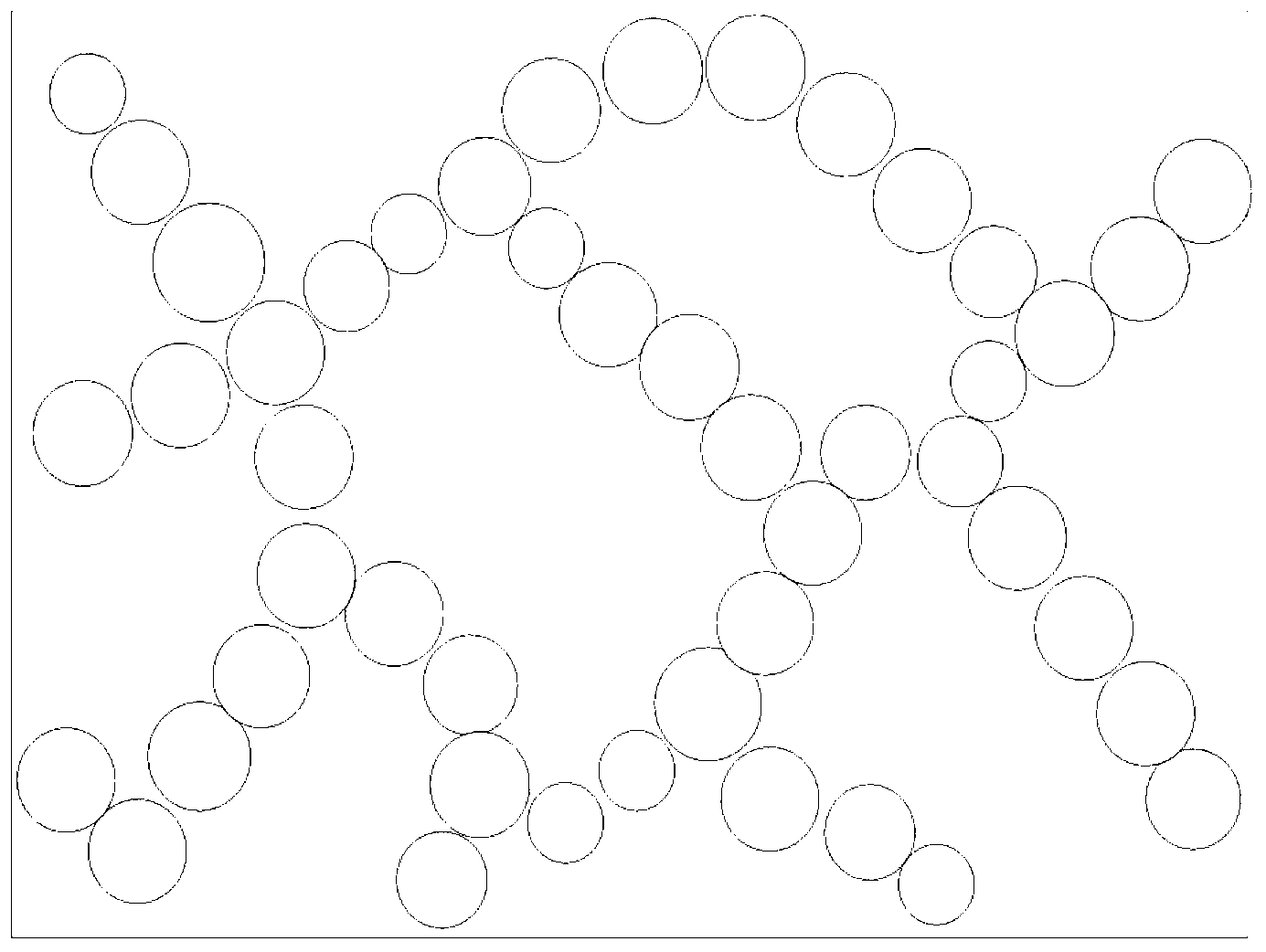

Image

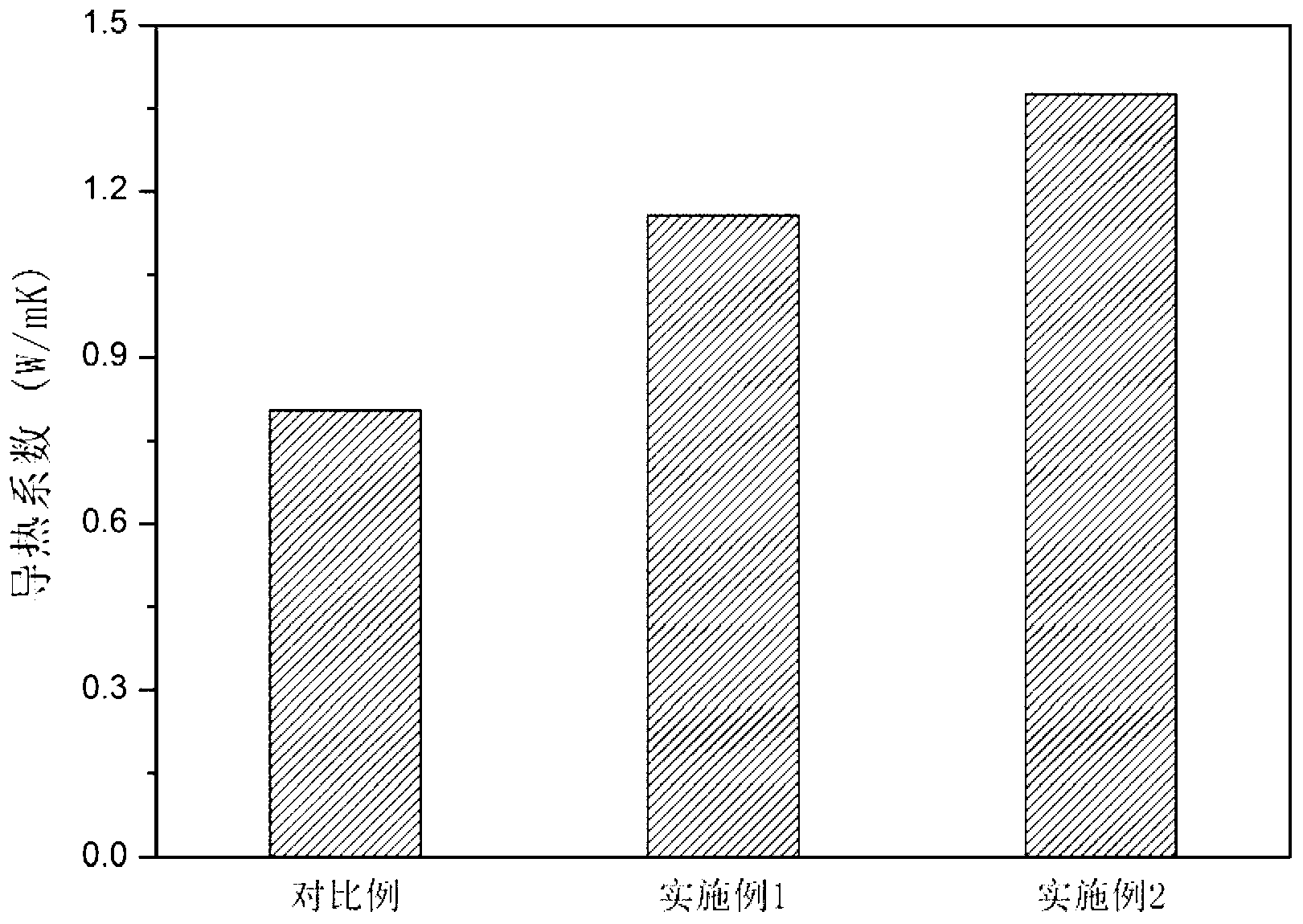

Examples

Embodiment 1

[0027] 1. Preparation of Epoxy Resin Powder

[0028] 1) Mix 100g of epoxy resin (E-51) and 23.4g of diethyltoluenediamine curing agent evenly, and cure at 120°C for 2.5h+180°C for 1h to obtain a cured epoxy resin;

[0029] 2) Put the epoxy resin cured product obtained in step 1) into the crushing equipment and pulverize it into epoxy resin powder with an average particle size of 70um.

[0030] 2. Preparation of amino group-containing aluminum nitride

[0031] Add 10g of aluminum nitride with an average particle size of 5um, 100mL of acetone and 0.1g of 3-aminopropyltrimethoxysilane into the reaction vessel, stir and ultrasonically vibrate for 50 minutes at 50°C, filter, wash and dry After drying, aluminum nitride containing amino groups is obtained.

[0032] 3. Preparation of high thermal conductivity epoxy resin

[0033] After mixing 81g of epoxy resin, 19g of diethyltoluenediamine curing agent, 10g of the epoxy resin powder prepared in Example 1 and 20g of the amino group...

Embodiment 2

[0036] 1. Preparation of Epoxy Resin Powder

[0037] 1) Mix 100g of epoxy resin (E-51) and 23.4g of diethyltoluenediamine curing agent evenly, and cure at 120°C for 2.5h+180°C for 1h to obtain a cured epoxy resin;

[0038] 2) Put the epoxy resin cured product obtained in step 1) into the crushing equipment and pulverize it into epoxy resin powder with an average particle size of 70um.

[0039] 2. Preparation of amino group-containing aluminum nitride

[0040] Add 10g of aluminum nitride with an average particle size of 5um, 100mL of acetone and 0.1g of 3-aminopropyltrimethoxysilane into the reaction vessel, stir and ultrasonically vibrate for 50 minutes at 50°C, filter, wash and dry After drying, aluminum nitride containing amino groups is obtained.

[0041] 3. Preparation of high thermal conductivity epoxy resin

[0042] After mixing 81g of epoxy resin, 19g of diethyltoluenediamine curing agent, 20g of the epoxy resin powder prepared in Example 1 and 20g of the amino group-c...

Embodiment 3

[0045] 1. Preparation of Polyurethane Powder

[0046] 1) Mix 100g polyether polyol and 100g diisocyanate evenly, and cure at room temperature for 15 minutes to obtain a polyurethane cured product;

[0047] 2) The polyurethane cured product obtained in step 1) is put into a ball milling equipment and ball milled into a polyurethane powder with an average particle size of 1000um.

[0048] 2. Preparation of Amino Alumina

[0049] Add 10g of alumina with an average particle size of 200um, 120mL of ethanol and 0.1g of 3-aminopropyltriethylmethoxysilane into the reaction vessel, stir and ultrasonically vibrate for 5 minutes at 80°C, filter, wash, After drying, amino group-containing alumina is obtained.

[0050] 3. Preparation of High Thermal Conductivity Polyurethane Resin

[0051] After uniformly mixing 50 g of polyether polyol, 50 g of diisocyanate, 1 g of the polyurethane resin powder prepared in Example 1 and 5 g of amino group-containing alumina prepared in Example 1, a pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com