Straight welded welding-slag-free wire enamel

A wire coating and welding slag technology, applied in coating, polyurea/polyurethane coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

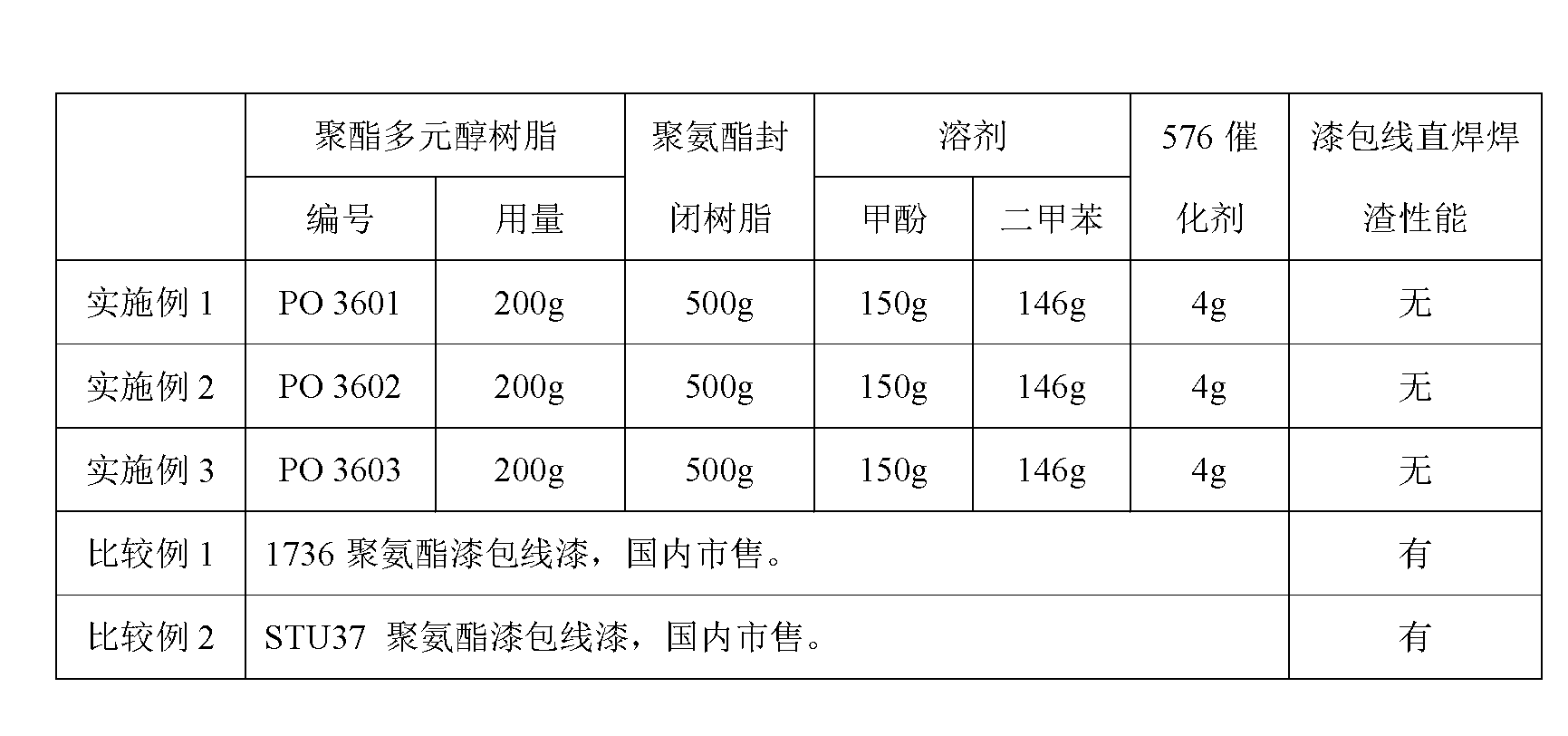

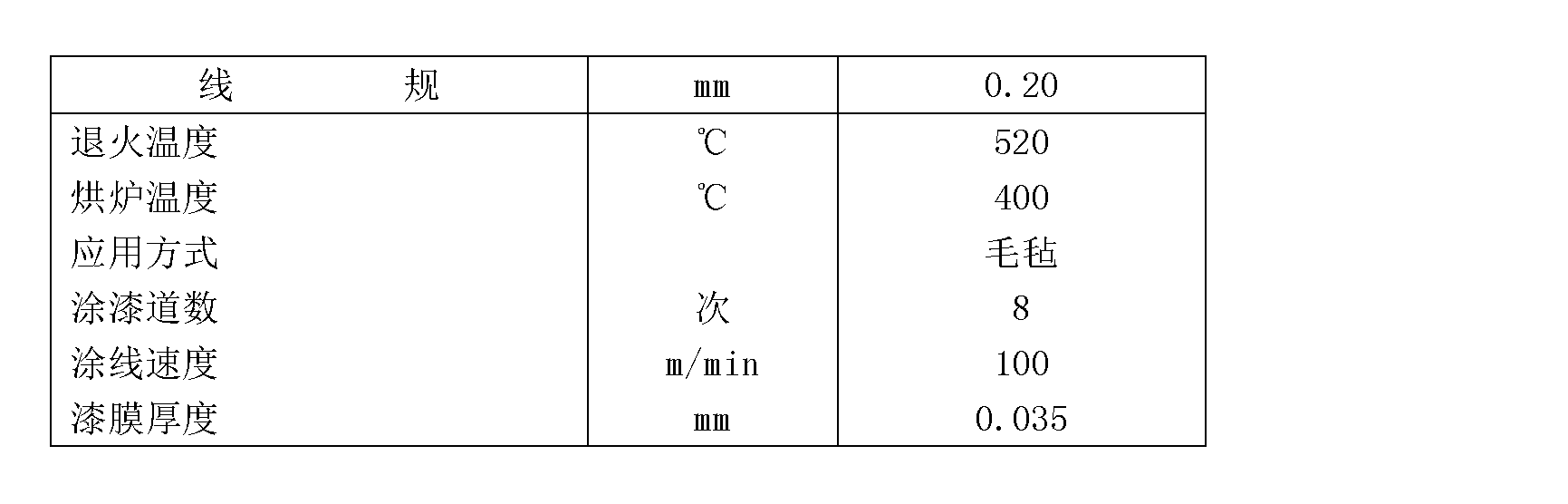

Examples

Embodiment Construction

[0028] The present invention is further described below in conjunction with example, but not limited thereto. The quantities in the following example formulations all refer to parts by weight.

[0029] 1. Preparation of polyester polyol resin

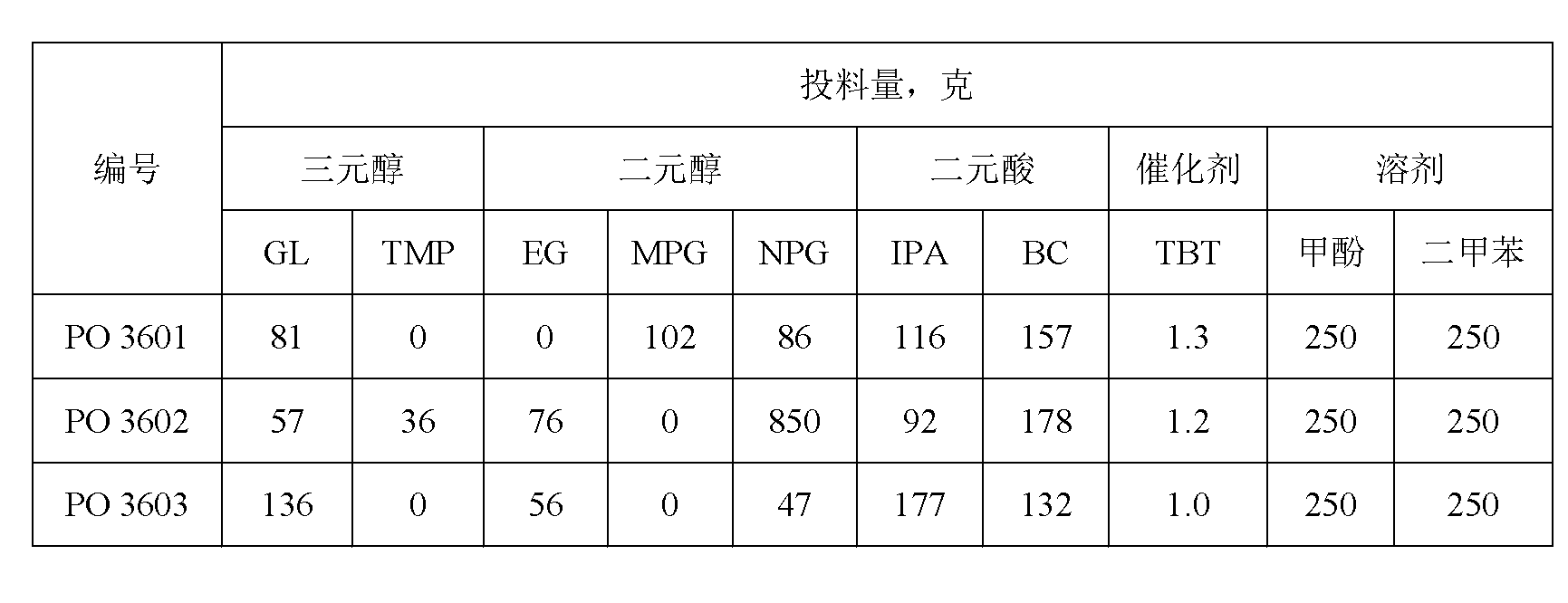

[0030] 1. See Table 1 for the formula

[0031] Table 1

[0032]

[0033] Abbreviations in Table 1: GL----glycerol, TMP----trimethylolpropane, EG----ethylene glycol, MPG----2-methyl-1,3-propanediol, NPG ----Neopentyl glycol, IPA----isophthalic acid, BC----phthalic anhydride, TBT----butyl titanate.

[0034] 2. Preparation process

[0035] Put in trihydric alcohol, dihydric alcohol, dibasic acid and catalyst, heat up, react at 160°C to 170°C for 1 hour, 170-180°C for 1 hour, 180-190°C for 3 hours, 190-200°C until the acid value is lower than 8mgKOH / g, then add cresol, cool down to 150°C, put in MDI in batches (guaranteed at 150-155°C), keep warm at 150-155°C for 1 hour, add solvent, stir at 90-100°C for 4 hours, and dilute .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com