Technique and device for continuously refining heavy liquid paraffin

A technology of heavy liquid paraffin and liquid paraffin, applied in the refining of petroleum wax, etc., can solve the problems of reducing iron ions and water, difficult water separation, incomplete separation of hydrochloric acid and liquid paraffin, etc., so as to improve quality and avoid clogging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

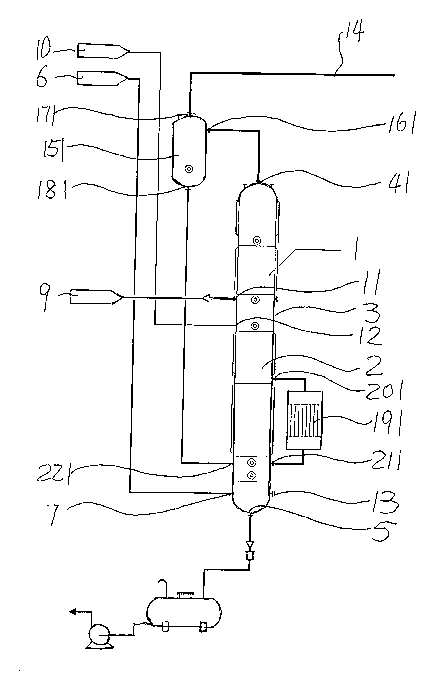

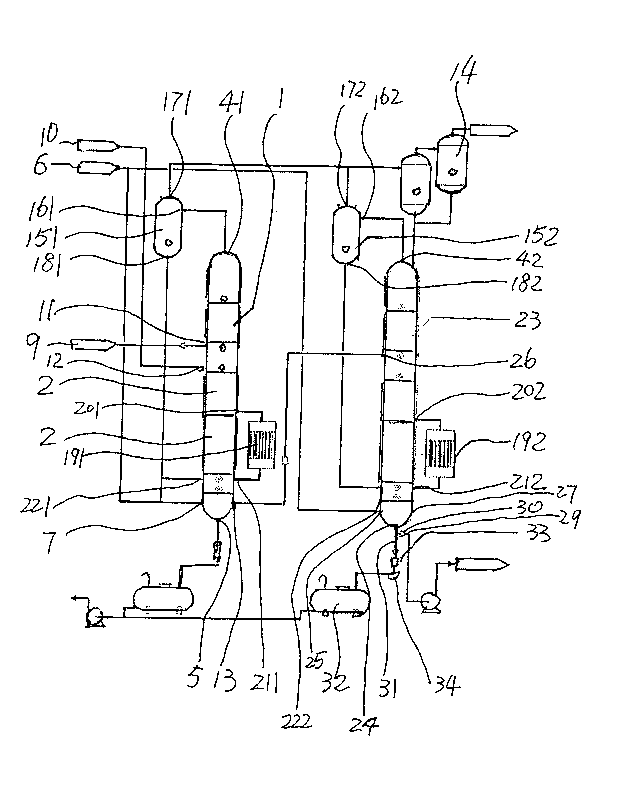

[0030] The structure and working principle of the method and device for continuously refining heavy liquid paraffin provided by the present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments:

[0031] The process of refining heavy liquid paraffin includes the following steps. The weight ratio is 1:0.5—0.55:0.01—0.02, preferably 1:0.5:0.01. Liquid paraffin, hydrogen chloride gas, and demineralized water are continuously fed through the pipeline at the same time. The first-stage reaction tower with a height of about 10 meters. In the reaction tower, the softened water absorbs hydrogen chloride and converts it into hydrochloric acid. At the same time, it releases heat energy to heat up the liquid paraffin. Under the action of heat, the hydrochloric acid produced further chemically reacts with the aromatic hydrocarbons, basic nitrogen and iron ions in the liquid paraffin to produce benzyl Base chloride, dichlorotol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com