Die-cast zinc alloy with high flowability and preparation method thereof

A high fluidity, zinc alloy technology, applied in the field of metal materials, to achieve grain refinement, improve comprehensive mechanical properties, and save costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

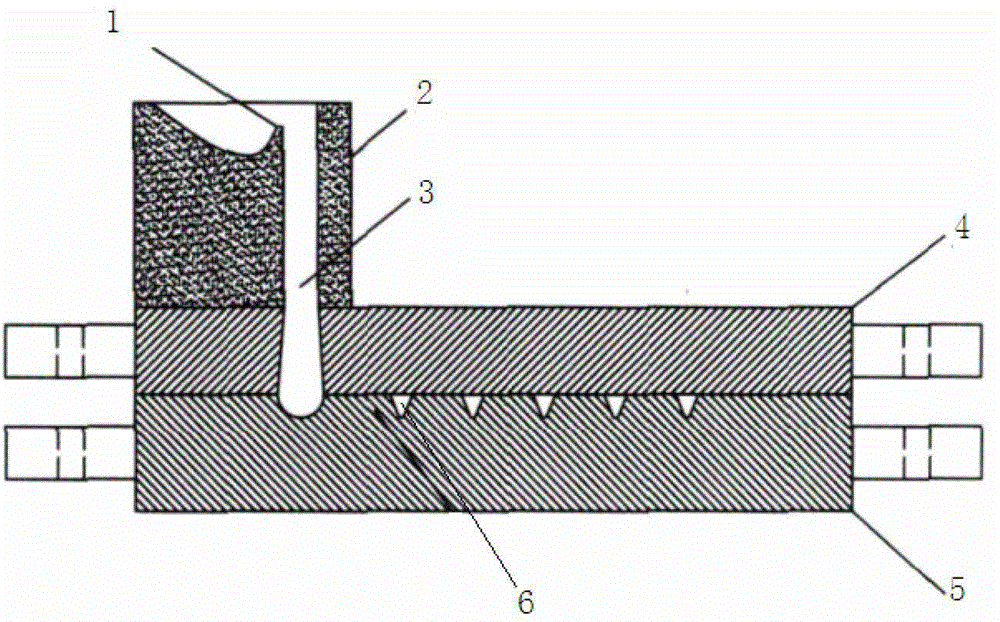

Method used

Image

Examples

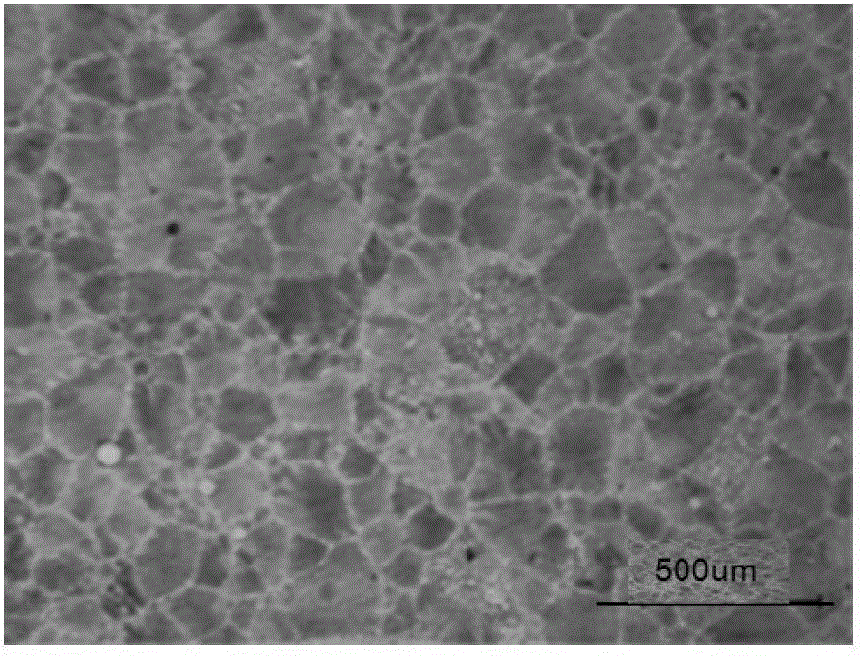

Embodiment 1

[0048] Pure Zn ingot with a purity greater than 99.97%, pure aluminum ingot with a purity greater than 99.7%, Al-11.07wt.%Mg master alloy, Al-37.4wt.%Cu master alloy, Zn-1wt.%Li master alloy and Al- 5Ti-B intermediate alloy is used as the raw material. First put the Al ingot into the melting furnace and raise the temperature to 700°C-720°C. After part of the aluminum liquid appears, add the covering agent, and cool down to 650°C-660°C after the Al ingot is completely melted. , adding Zn ingot, Al-Mg and Al-Cu master alloy, after melting, the pre-alloy liquid is obtained, the mass percentage of each element in the pre-alloy liquid is: Al4.53%, Mg0.02%, Cu0.5%, Li0 .02%, the total content of Pb, Cd, Fe, Sn unavoidable impurity elements is less than 0.02%, and the balance is Zn; use 0.3% NH in the total weight of the pre-alloying liquid 4 The Cl refining agent refines the pre-alloy liquid and removes slag; at 680°C-700°C, add Al-5Ti-B master alloy with a total weight of 0.6% of t...

Embodiment 2

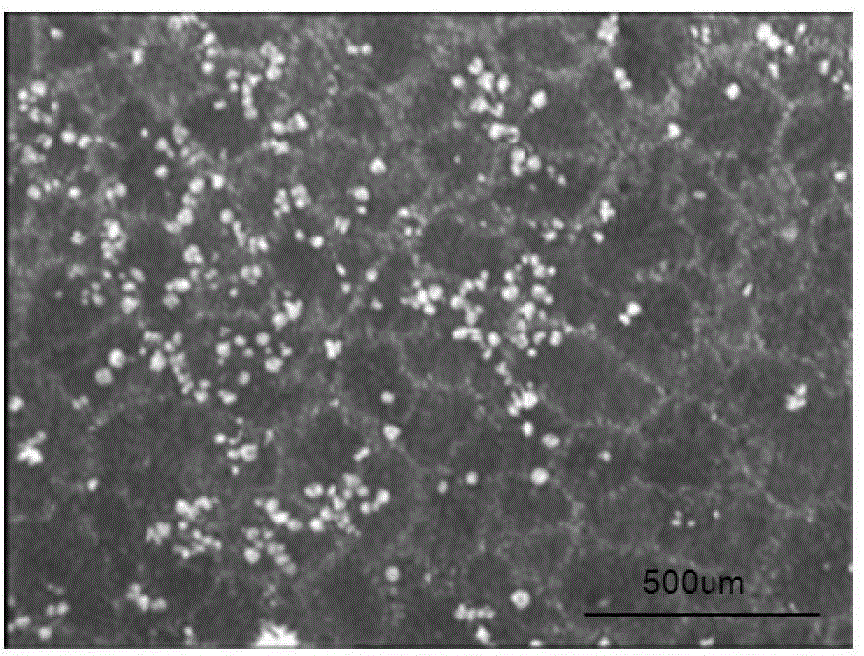

[0050] Pure Zn ingot with a purity greater than 99.97%, pure aluminum ingot with a purity greater than 99.7%, Al-11.07wt.%Mg master alloy, Al-37.4wt.%Cu master alloy, Zn-1wt.%Li master alloy and Al- 5Ti-B intermediate alloy is used as the raw material. First put the Al ingot into the melting furnace and raise the temperature to 680°C-700°C. After part of the aluminum liquid appears, add the covering agent and cool down to 670°C-680°C after the Al ingot is completely melted. , adding Zn ingot, Al-Mg and Al-Cu master alloy, after melting, the pre-alloy liquid is obtained, the mass percentage of each element in the pre-alloy liquid is: Al4.51%, Mg0.04%, Cu0.6%, Li0 .02%, the total content of Pb, Cd, Fe, Sn unavoidable impurity elements is less than 0.02%, and the balance is Zn; use 0.3% NH in the total weight of the pre-alloying liquid 4 The Cl refining agent refines the pre-alloy liquid and removes slag; at 680°C-700°C, add Al-5Ti-B master alloy with a total weight of 1.5%, stir...

Embodiment 3

[0052] Pure Zn ingot with a purity greater than 99.97%, pure aluminum ingot with a purity greater than 99.7%, Al-11.07wt.%Mg master alloy, Al-37.4wt.%Cu master alloy, Zn-1wt.%Li master alloy and Al- 5Ti-B intermediate alloy is used as the raw material. First put the Al ingot into the melting furnace and raise the temperature to 680°C-700°C. After part of the aluminum liquid appears, add the covering agent, and cool down to 660°C-670°C after the Al ingot is completely melted. , adding Zn ingots, Al-Mg and Al-Cu master alloys, after melting, a pre-alloy liquid is obtained, and the mass percentages of each element in the pre-alloy liquid are: Al4.52%, Mg0.06%, Cu0.5%, Li0 .01%, the total content of Pb, Cd, Fe, Sn unavoidable impurity elements is less than 0.02%, and the balance is Zn; the pre-alloying liquid is refined with NH4Cl refining agent with a total weight of 0.3% of the pre-alloying liquid, and the slag is removed; at 690 ℃-700℃, add Al-5Ti-B master alloy of 0.9% of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| grain size | aaaaa | aaaaa |

| Brinell hardness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com