Method for distinguishing quality of yeast

A Daqu quality technology, applied in the field of identifying the quality of Daqu, to achieve the effect of simple operation, good reproducibility and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

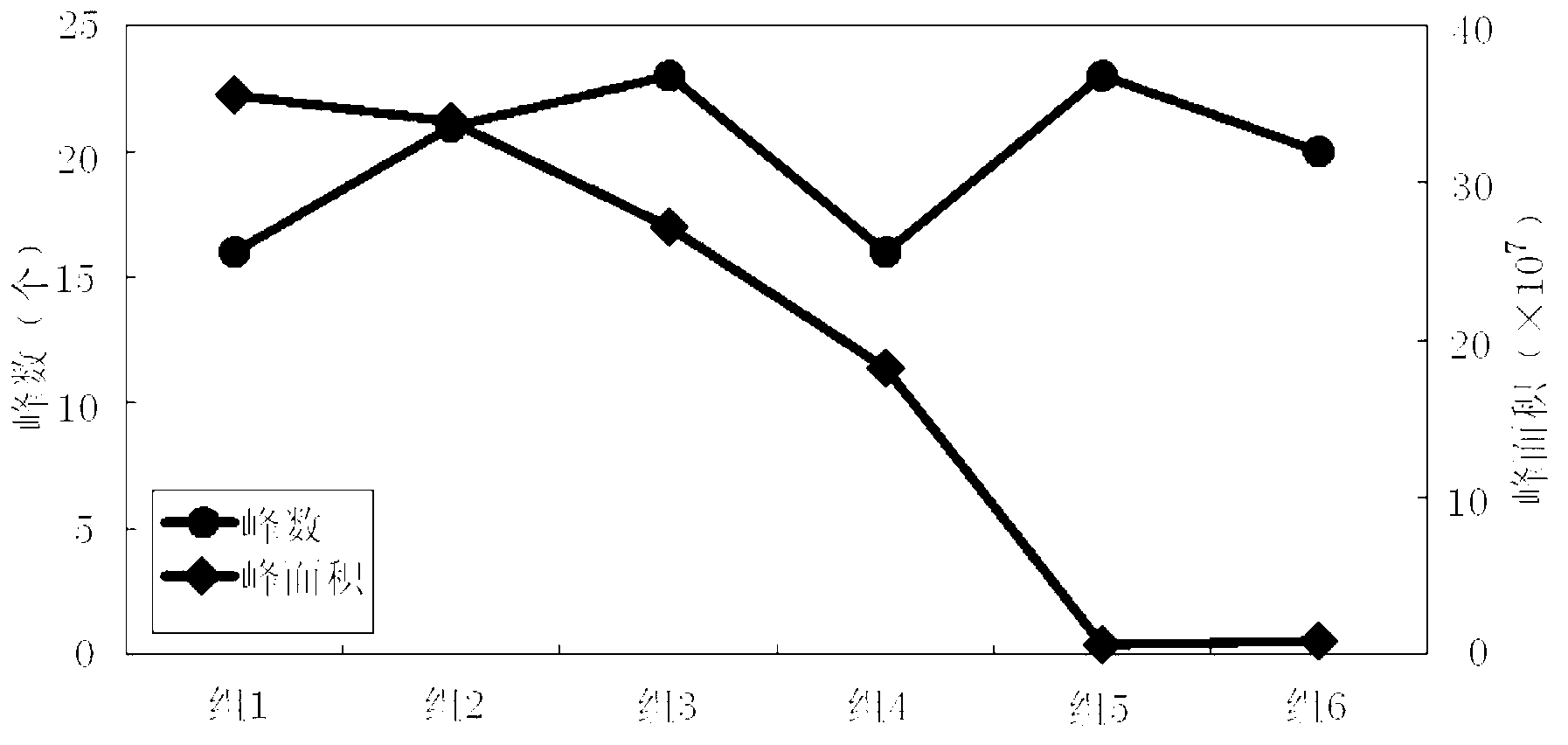

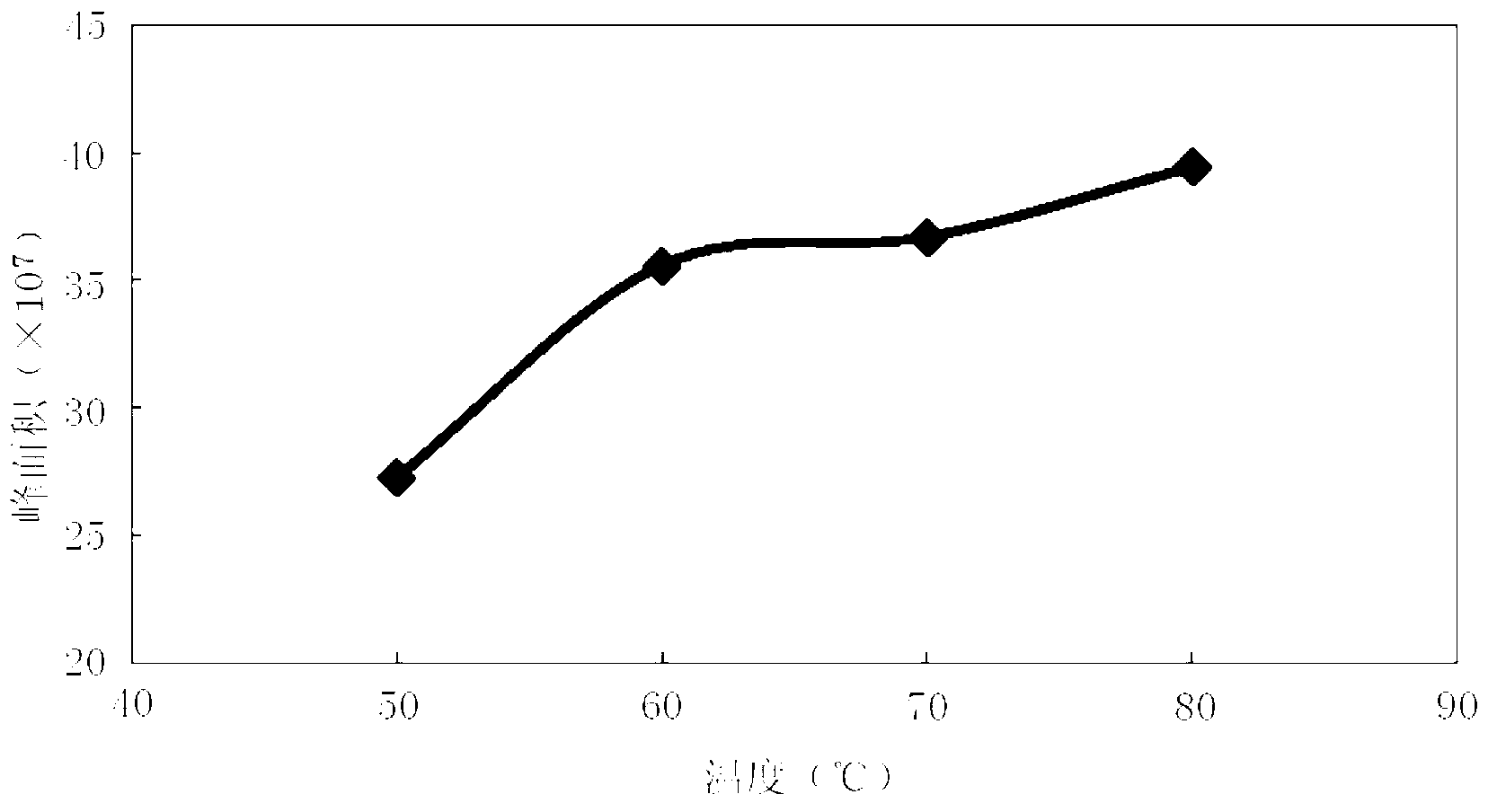

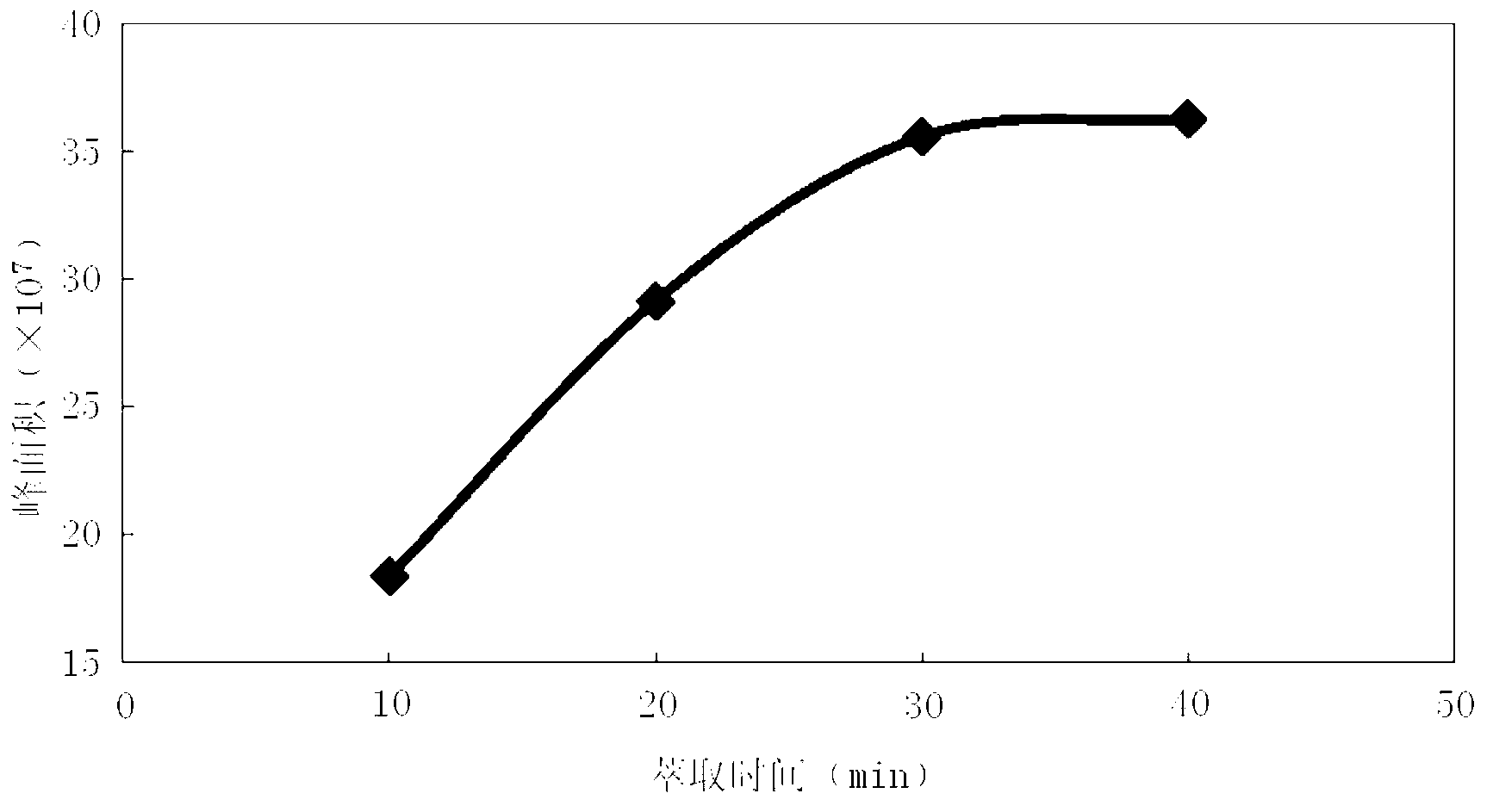

[0077] (1) Solid-phase microextraction of Daqu samples:

[0078] Add 2g of the pulverized finished koji sample into a 20ml headspace sample bottle for solid-phase microextraction injection, the heating temperature is 60°C, and the extraction time is 20min;

[0079] (2) Gas chromatography-mass spectrometry analysis:

[0080] Carry out gas chromatography-mass spectrometry analysis, that is, after being separated by gas chromatograph GC, enter mass spectrometer MS for analysis, and the analysis conditions of gas chromatography-mass spectrometry are:

[0081] Inlet temperature: 250°C; ionization method: EI; ion source temperature: 230°C; transfer line temperature: 230°C; carrier gas: helium; constant flow rate 1.5ml / min; column: capillary gas chromatography column 60m×0.25 mm×0.25μm; gas chromatography heating program: initial temperature 40°C, keep 2min, heating rate 5°C / min, to 230°C, keep 10min; mass spectrometry scanning mode: use full scan mode;

[0082] (3) Qualitative ana...

Embodiment 2

[0088] (1) Solid-phase microextraction of Daqu samples:

[0089] Add 2g of the pulverized yellow koji sample into a 20ml headspace sample bottle for solid-phase microextraction, heating at 60°C, and extracting for 30 minutes;

[0090] (2) Gas chromatography-mass spectrometry analysis:

[0091] Carry out gas chromatography-mass spectrometry analysis, that is, after being separated by gas chromatograph GC, enter mass spectrometer MS for analysis, and the analysis conditions of gas chromatography-mass spectrometry are:

[0092] Inlet temperature: 250°C; ionization method: EI; ion source temperature: 230°C; transfer line temperature: 230°C; carrier gas: helium; constant flow rate 1ml / min; column: capillary gas chromatography column 60m×0.25mm ×0.25μm; gas chromatography heating program: initial temperature 40°C, keep 2min, heating rate 6°C / min, to 230°C, keep 10min; mass spectrometry scanning mode: use full scan mode;

[0093] (3) Qualitative analysis of substances:

[0094] Qu...

Embodiment 3

[0099] (1) Solid-phase microextraction of Daqu samples:

[0100] Add 4g of pulverized white koji samples into a 20ml headspace sample bottle for solid phase microextraction injection, the heating temperature is 80°C, and the extraction time is 40min;

[0101] (2) Gas chromatography-mass spectrometry analysis:

[0102] Carry out gas chromatography-mass spectrometry analysis, that is, after being separated by gas chromatograph GC, enter mass spectrometer MS for analysis, and the analysis conditions of gas chromatography-mass spectrometry are:

[0103] Inlet temperature: 250°C; ionization method: EI; ion source temperature: 230°C; transfer line temperature: 230°C; carrier gas: helium; constant flow rate 1.5ml / min; column: capillary gas chromatography column 60m×0.25 mm×0.25μm; gas chromatography heating program: initial temperature 40°C, hold for 4 minutes, heating rate 8°C / min, to 230°C, hold for 10 minutes; mass spectrometry scanning mode: use full scan mode;

[0104] (3) Qua...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com