A Complete Set of Optimal Control Method for Ethylene Cracking Furnace

An ethylene cracking furnace and optimization control technology, applied in the field of control, can solve the problems of large fluctuation of the total feed flow rate of the cracking furnace and high energy consumption of the cracking furnace, and achieve the effects of stable COT control, energy saving optimization, and yield increase.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

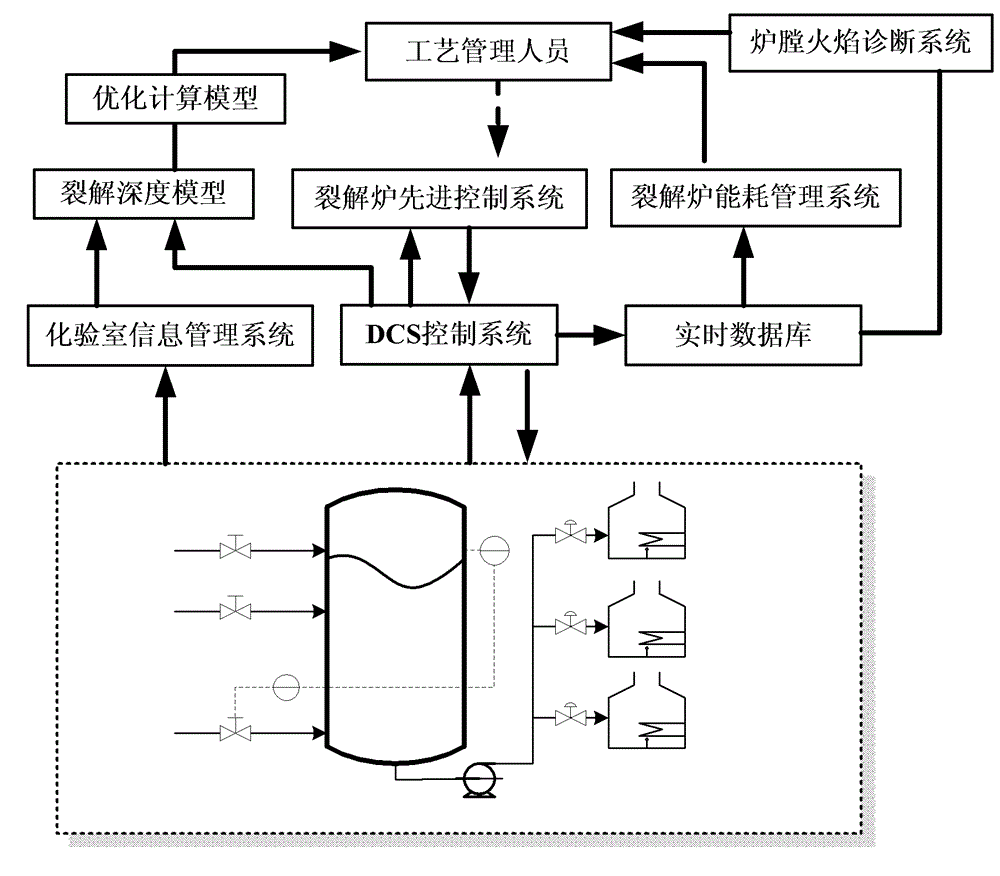

[0022] In order to make the object, technical solution and advantages of the present invention clearer, the implementation manner of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0023] see figure 1 , according to the status and needs of process production, the cracking depth model collects data from the laboratory information management system and DCS control system. The data of the laboratory information management system comes from laboratory analysis, and the data of the DCS control system comes from field instruments to calculate the key operating indicators of the cracking furnace. COT and oil-steam ratio, the results are input into the optimization calculation model together with data such as cracking furnace coke cleaning and energy consumption, and the optimal control index of COT and oil-steam ratio is calculated with the optimization goal of minimizing energy consumption, and the calculated data are p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com