Method and device for producing ions used for analysis under low pressure

An ion and ion focusing technology, applied in the parts of the particle separator tube, particle separation tube, ion source/gun, etc., can solve the problems of loss and insufficient sensitivity of the ion source, achieve high sensitivity, increase the application range, improve the The effect of sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

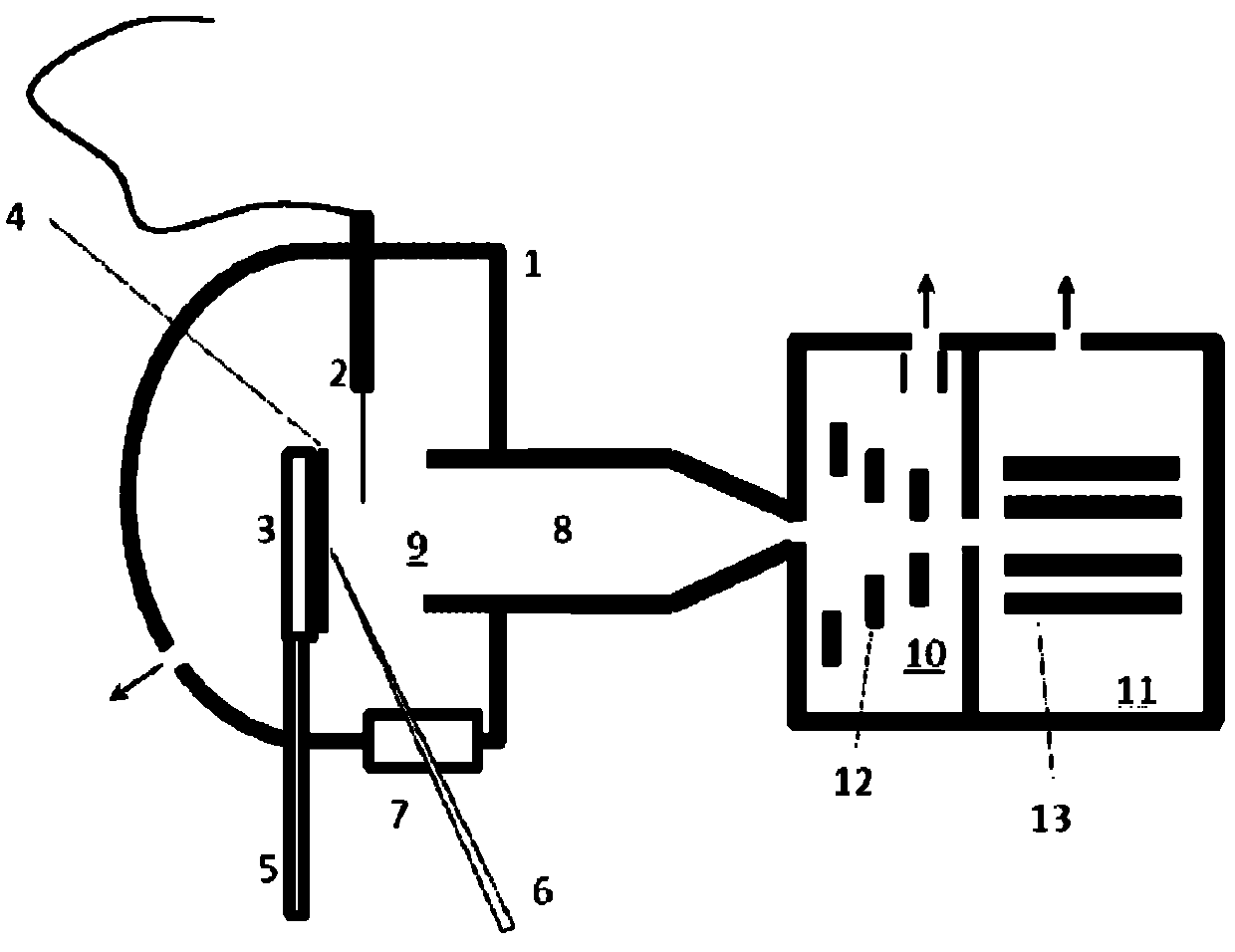

[0053] Such as figure 1 Shown is an example according to the first embodiment of the present invention, in which 1 is the vacuum cavity where the ion source is located, and the electrospray needle 2 generates electrospray after applying high voltage. The electrospray needle is a nanoliter spray tip. The direction of the spray needle is perpendicular to the transport direction of the ion funnel. After necessary desolvation measures, the charged droplets generated by the electrospray pass through the ion focusing device (the ion funnel 8, the Q-array guide 12 and the octopole rod 13 in sequence), and then enter the analyzer for analysis. The sample stage 3 and the sample holder 4 placed on it together form a sample platform. The sample stage 3 is connected to the mechanical device and is controlled to move, and under the condition of not breaking the vacuum of the cavity, the sample stage 3 and the sample holder 4 pass through the vacuum together. The introduction device 5 mov...

Embodiment 2

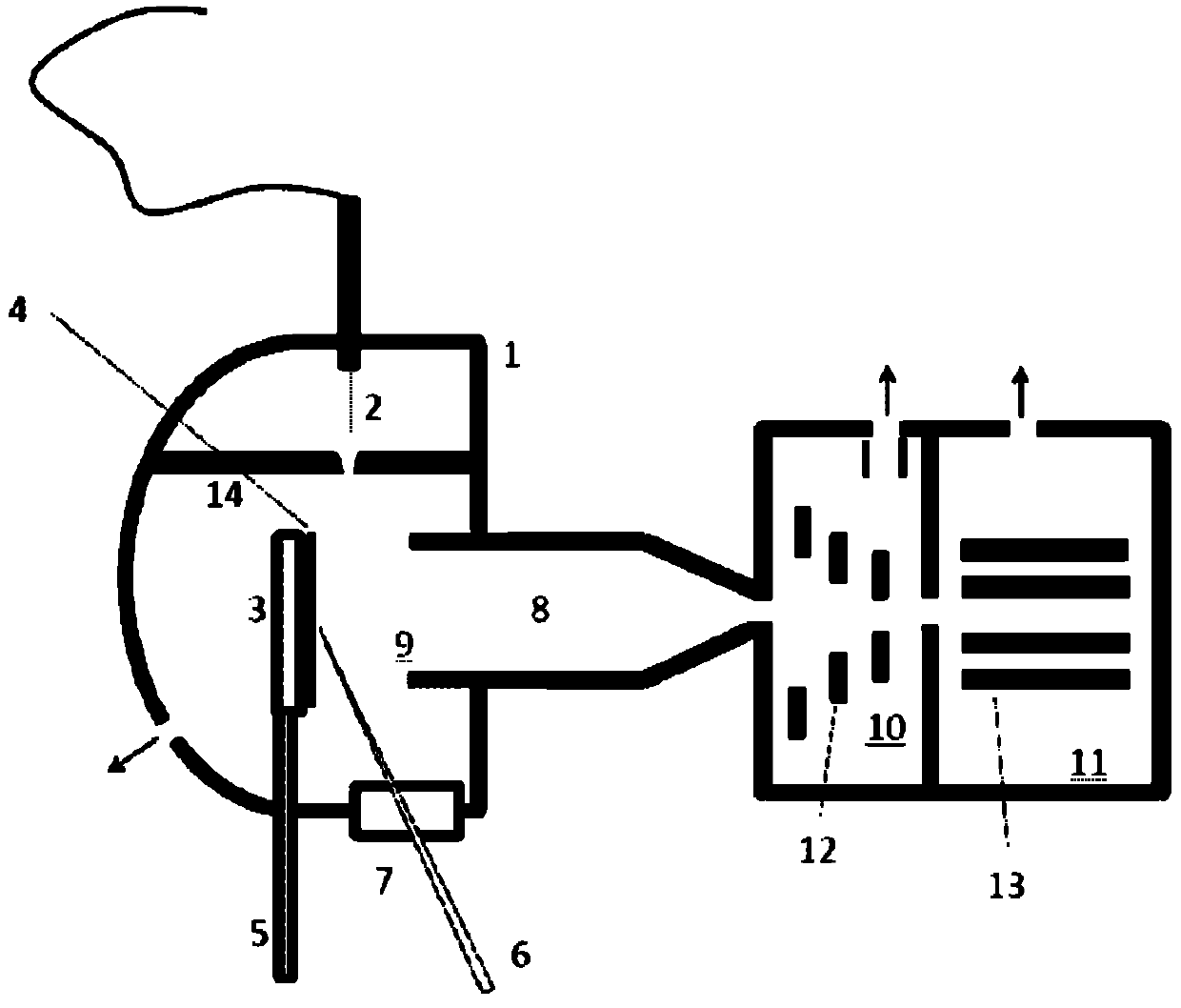

[0056] figure 2 This is a modified example of the first embodiment of the present invention. On the basis of the original embodiment, this modification adds a flange 14 with a small hole, the flange is located between the low-pressure spray needle and the matrix-assisted laser desorption ionization area, and the suction port of the mechanical pump is still located in the area of the laser desorption ionization area. In the region, a differential pumping step more than that in Embodiment 1 is formed, so that the two ionization sources work more suitable for different pressure ranges.

Embodiment 3

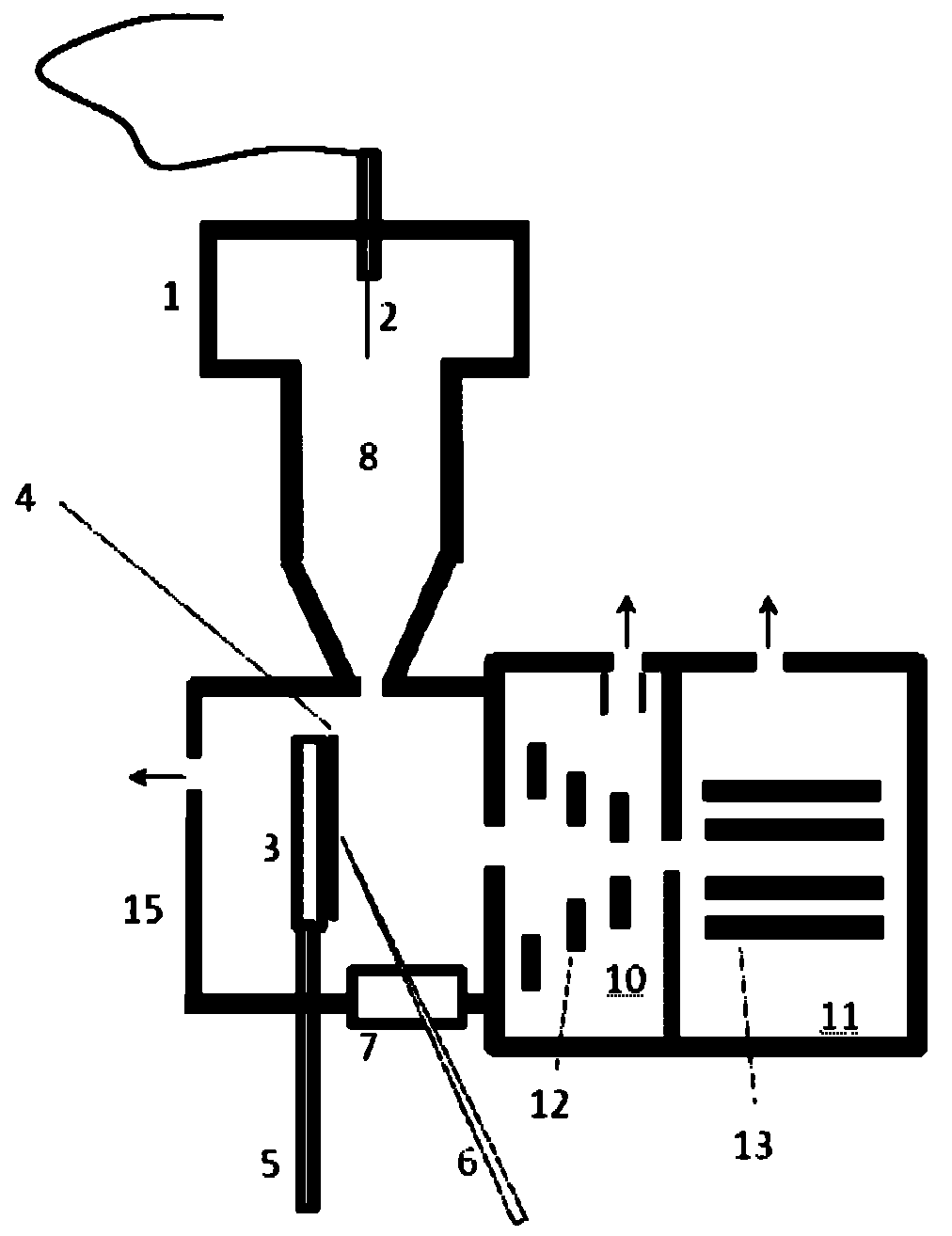

[0058] image 3 This is another modified example of the first embodiment of the present invention. In this modification, the ion funnel 8 in the previous modification is moved to the cavity of the needle and used to replace the small hole 14 of the flange. At this time, the electrospray works at 10-30 torr, and the air pressure inside the vacuum chamber 15 where matrix-assisted laser desorption ionization works is 1-2 torr or even lower.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com