Diammonium glycyrrhizinate enteric-coated pellet as well as preparation method and preparation thereof

A technology of diammonium glycyrrhizinate and enteric-coated pellets, applied in the field of medicine, can solve the problems of reducing drug efficacy, absorption, uneven distribution, low bioavailability, etc., to avoid damage, ensure stability, and improve bioavailability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] The preparation of embodiment 1 diammonium glycyrrhizinate enteric-coated pellets

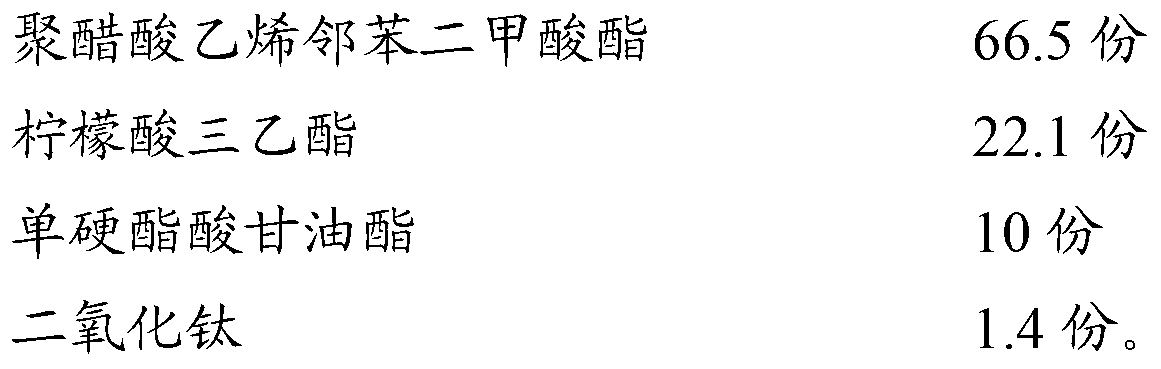

[0056] Take 100g of diammonium glycyrrhizinate and mix it with 120g of starch and 120g of microcrystalline cellulose to form a uniform powder to obtain the first product; add another 2g of starch to 100mL of boiling water to form the second product; take 5g of PVPk 30 , add 100mL ethanol aqueous solution (the volume percentage of ethanol is 30%) to prepare the third product; take 68g enteric coating material and dissolve it in 400mL water to prepare the coating liquid. Add the first product into the fluidized bed, spray into the second product, prepare and screen 35-50 mesh mother cores, place in the fluidized bed and continue to spray the first product and the third product, increase the preparation of pellets, dry, Take 20-mesh to 24-mesh pellets, put them in a fluidized bed, spray into the coating solution and coat them to prepare enteric-coated pellets, dry them, and obtain.

Embodiment 2

[0057] The preparation of embodiment 2 diammonium glycyrrhizinate enteric-coated pellets

[0058] Take 100g of diammonium glycyrrhizinate, mix it with 150g of dextrin and 150g of mannitol to form a uniform powder, and get the first product; add another 2g of dextrin to 100mL boiling water to make the second product; take 5g of hypromellose, add 100mL of ethanol aqueous solution (the volume percentage of ethanol is 30%) was prepared as the third product; 80g of enteric coating material was dissolved in 400mL of water to prepare a coating liquid. Add the first product into the fluidized bed, spray into the second product, prepare and screen 35-50 mesh mother cores, place in the fluidized bed and continue to spray the first product and the third product, increase the preparation of pellets, dry, Take 20-mesh to 24-mesh pellets, put them in a fluidized bed, spray into the coating solution and coat them to prepare enteric-coated pellets, dry them, and obtain.

Embodiment 3

[0059] The preparation of embodiment 3 diammonium glycyrrhizinate enteric-coated pellets

[0060] Take 100g of diammonium glycyrrhizinate, mix it with 400g of starch and 400g of microcrystalline cellulose to form a uniform powder, and get the first product; add another 10g of starch into 500mL of boiling water to make the second product; take 20g of PVPk 30 , add 400mL ethanol aqueous solution (the volume percentage of ethanol is 30%) to prepare the third product; take 180g enteric coating material and dissolve it in 900mL water to prepare the coating solution. Add the first product into the fluidized bed, spray into the second product, prepare and screen 35-50 mesh mother cores, place in the fluidized bed and continue to spray the first product and the third product, increase the preparation of pellets, dry, Take 20-mesh to 24-mesh pellets, put them in a fluidized bed, spray into the coating solution and coat them to prepare enteric-coated pellets, dry them, and obtain.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com