Metal organic framework structure-based fluorine removal agent and preparation method thereof

A technology for removing fluorine agent and metal salt, applied in the field of fluorine removing agent and its preparation, can solve the problems of low adsorption capacity, secondary pollution, aluminum loss, etc., and achieve the effects of high adsorption capacity, easy operation, and avoidance of structural stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Preparation of metal salt solution: Dissolve 1 mol of aluminum nitrate in 1L of water to prepare a metal salt solution;

[0034] (2) Preparation of trimesic acid solution: Dissolve 1 mol of trimesic acid in 1 L of DMF solution to form a 1 mol / L trimesic acid solution;

[0035] (3) Preparation of metal-organic framework defluoridation agent: Mix the prepared metal salt solution and trimesic acid solution at a volume ratio of 1:1, then add it to a 100ml conical flask with a stopper, put it in an oven, and set it at 100°C Heating under the same conditions for 12 hours, then washing with DMF for several times, and drying in vacuum to obtain the powdered defluorinating agent Al-BTC.

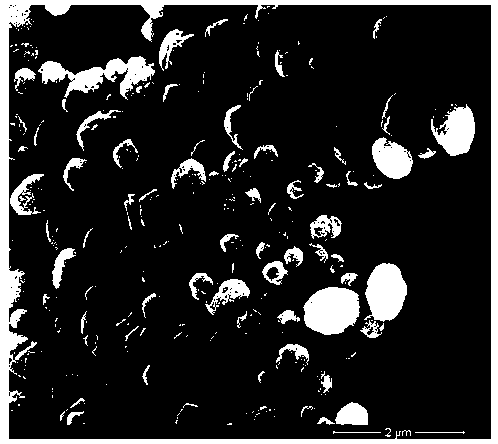

[0036] figure 1 It is the result of characterizing the prepared target product with a scanning electron microscope (SEM), and the SEM photo clearly shows that the target product is composed of ellipsoidal particles smaller than 1 μm.

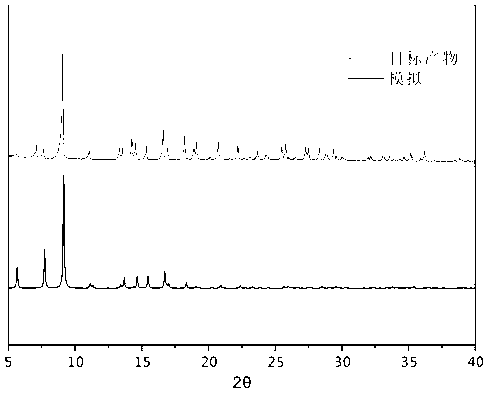

[0037] figure 2 is true figure 1 One of the resu...

Embodiment 2

[0041] (1) Preparation of metal salt solution: Dissolve 1 mol of aluminum oxalate in 1L of water to prepare a metal salt solution;

[0042] (2) Preparation of trimesic acid solution: Dissolve 0.8 mol of terephthalic acid in 1 L of DMSO solution to form a 0.8 mol / L terephthalic acid solution;

[0043] (3) Preparation of metal-organic framework defluorination agent: Mix the prepared metal salt solution and terephthalic acid solution at a volume ratio of 1:3, then add it to a 100ml conical flask with a stopper, put it in an oven at 90°C Heating under the conditions for 12 hours, then washing with DMSO for several times, and drying in vacuum to obtain a powdery defluorinating agent.

[0044]

Embodiment 3

[0046] (1) Preparation of metal salt solution: Dissolve 2mol of aluminum acetate in 1L of water to prepare a metal salt solution;

[0047] (2) Preparation of trimesic acid solution: Dissolve 2 mol of terephthalic acid in 1 L of ether solution to form a 2 mol / L terephthalic acid solution;

[0048] (3) Preparation of metal-organic framework defluoridation agent: Mix the prepared metal salt solution and terephthalic acid solution at a volume ratio of 1:2, then add it to a 100ml conical flask with a stopper, put it in an oven, and set it at 90°C Heating under the conditions for 36 hours, then washing several times with ether, and drying in vacuum to obtain a powdery defluorinating agent.

[0049]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com