Method and system for separating particle mixture

A separation method and separation system technology are applied in the field of separation methods and systems for crushing particles of waste electronic circuit boards, which can solve the problems of high impurities in copper powder, high cost, low separation efficiency, etc. Efficiency and precision, the effect of simple system structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

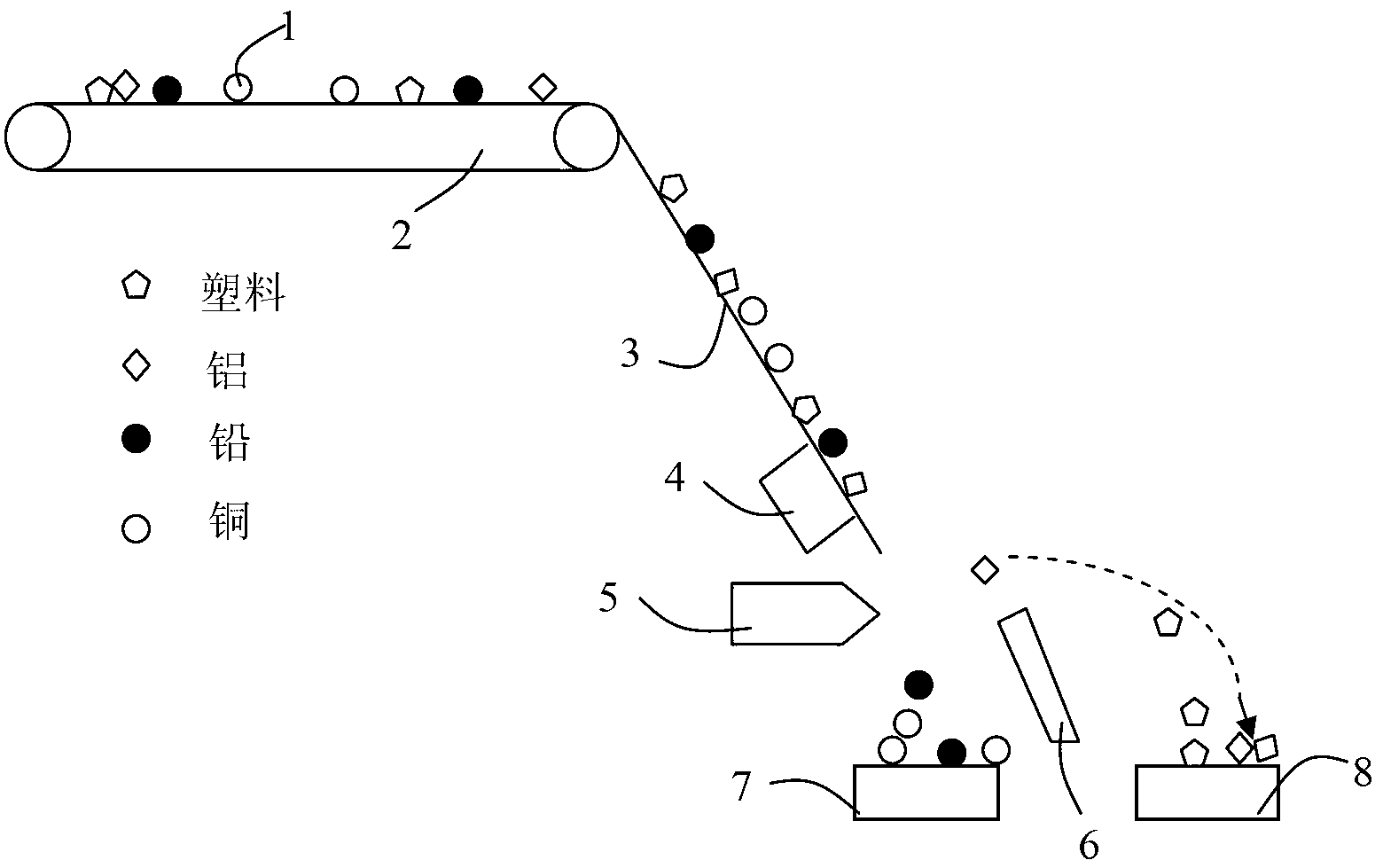

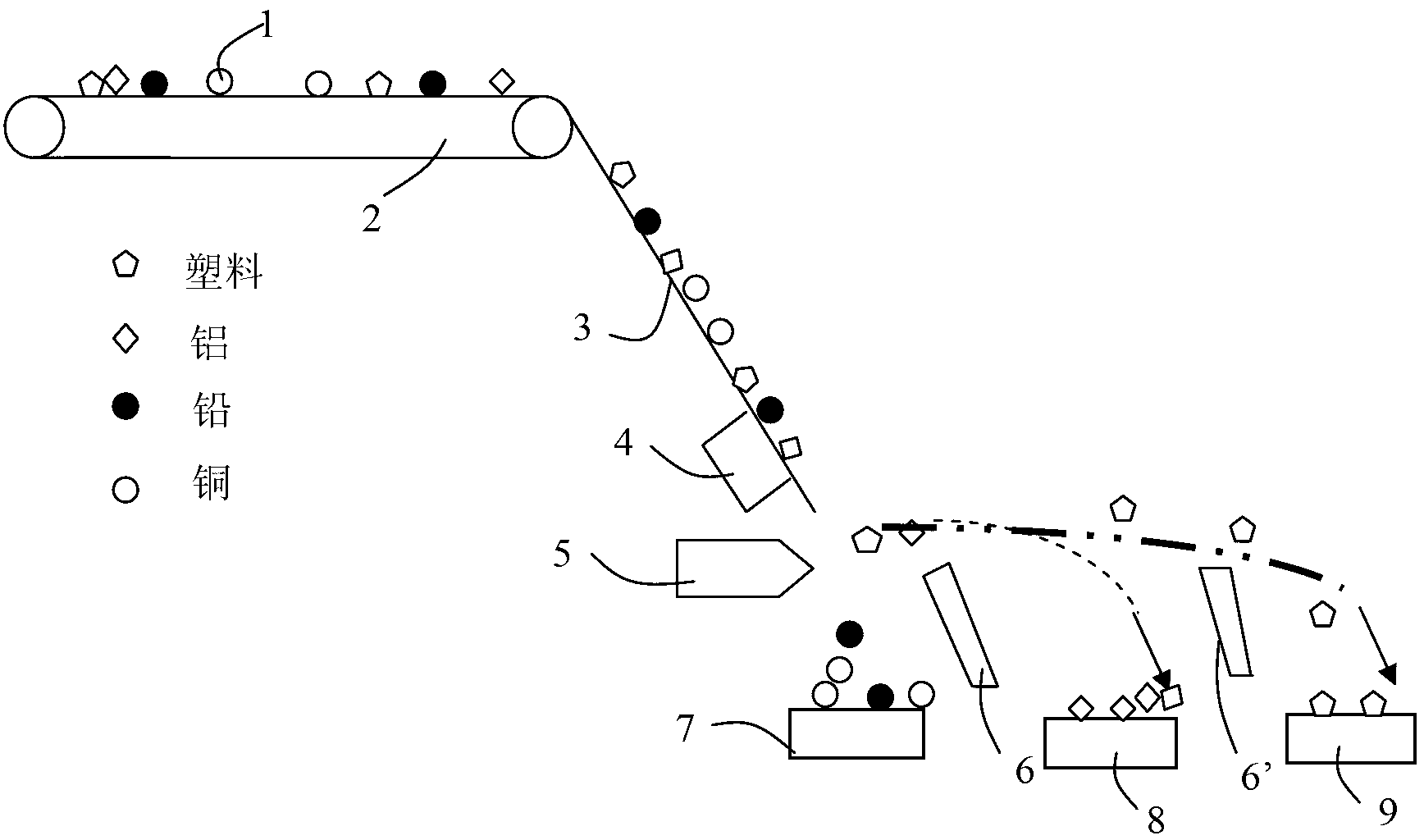

[0024] See figure 1 , Is an embodiment of the particle mixture separation system of the present invention.

[0025] The particle mixture separation system of this embodiment includes a feeding device, a separation device and a collection device.

[0026] The feeding device is used to convey the particle mixture to the separation device. In this embodiment, the conveyor belt 2 is used as the feeding device.

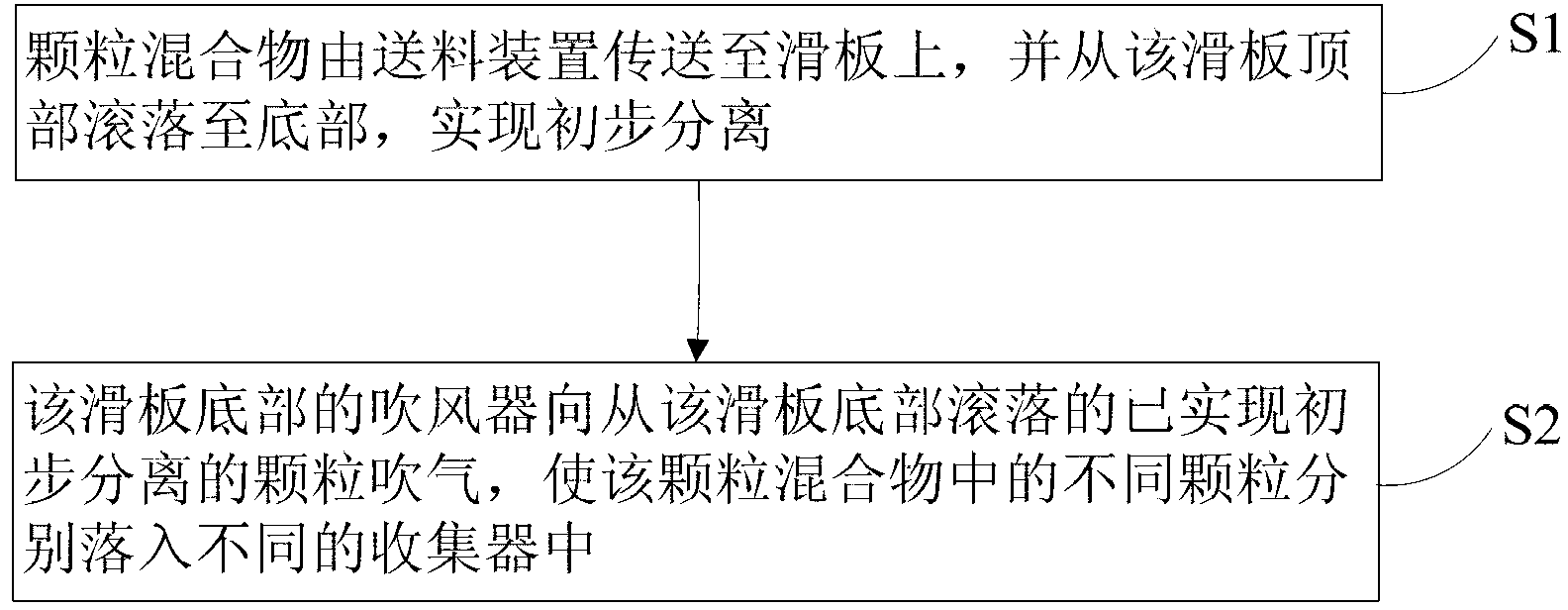

[0027] The separating device includes a sliding plate 3, a gravity sensor 4 and a hair dryer 5. The sliding plate 3 is located at the tail of the conveyor belt 2 and is inclined downward, and is used to receive the granular mixture 1 conveyed by the conveyor belt 2. Adjusting the inclination of the sliding plate 3 (it is generally appropriate to adjust the inclination between 30° and 60°) can enable the particle mixture 1 to achieve preliminary separation when passing the gravity sensor 4. The gravity sensor 4 and the hair dryer 5 are installed at the bottom of the skateboard 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com