Method and device for recycling ammonium chloride from glycine mother liquor

A technology of glycine mother liquor and ammonium chloride, applied in ammonium halide and other directions, can solve the problems of poor operation continuity, limited production capacity, large plant footprint, etc., and achieve the effects of easier process control, fast evaporation rate, and reduced plant investment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

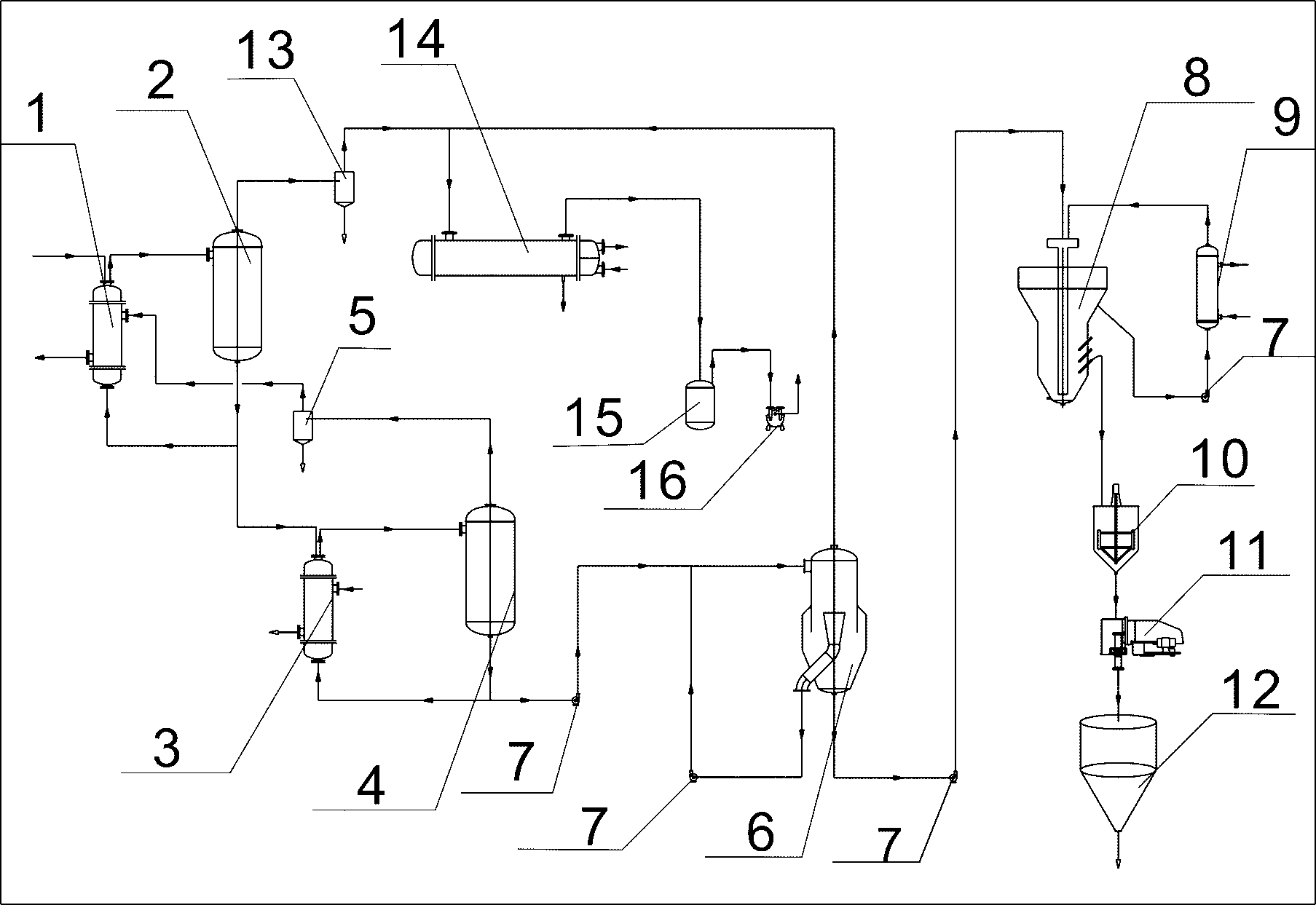

Image

Examples

Embodiment 1

[0011] Pass the mother liquor of glycine into the I-effect heater and heat it to 75°C, and then enter the I-effect evaporator and adopt vacuum preliminary evaporation and concentration, the vacuum degree of which is -0.06MPa; The difference enters the II-effect heater, and is heated to 107°C with steam, and enters the II-effect evaporator for further evaporation and concentration; the concentrated liquid in the above-mentioned II-effect evaporator is sent to the flash evaporator, and the concentrated liquid is discharged in the flash The pump is used for circulating concentration, and the concentration is flashed at a vacuum of -0.05 MPa to make the mass concentration of the concentrated solution reach 45%; the above-mentioned flashed concentrated solution is sent to the continuous crystallizer, and the continuous crystallizer is used for circulating heat exchange and cooling Crystallization; the solid-liquid mixed phase at the bottom of the continuous crystallizer is passed in...

Embodiment 2

[0013] Pass the mother liquor of glycine into the I-effect heater and heat it to 70°C, and then enter the I-effect evaporator and use vacuum preliminary evaporation and concentration, the vacuum degree of which is -0.07MPa; The difference enters the II-effect heater, and is heated to 103°C with steam, and enters the II-effect evaporator for further evaporation and concentration; the concentrated liquid in the above-mentioned II-effect evaporator is sent to the flash evaporator, and the concentrated liquid is discharged in the flash The pump is used for circulating concentration, and the concentration is flashed at a vacuum of -0.06 MPa to make the mass concentration of the concentrated solution reach 47%; the above-mentioned flashed concentrated solution is sent to the continuous crystallizer, and the continuous crystallizer is used for circulating heat exchange and cooling Crystallization; the solid-liquid mixed phase at the bottom of the continuous crystallizer is passed into...

Embodiment 3

[0015] Pass the mother liquor of glycine into the I-effect heater and heat it to 75°C, and then enter the I-effect evaporator and use vacuum preliminary evaporation and concentration, the vacuum degree of which is -0.07MPa; The difference enters the II-effect heater, and is heated to 102°C with steam, and enters the II-effect evaporator for further evaporation and concentration; the concentrated liquid in the above-mentioned II-effect evaporator is sent to the flash evaporator, and the concentrated liquid is discharged in the flash The pump is used for circulating concentration, and the concentration is flashed at a vacuum of -0.07 MPa to make the mass concentration of the concentrated solution reach 45%; the above-mentioned flashed concentrated solution is sent to the continuous crystallizer, and the continuous crystallizer is used for circulating heat exchange and cooling Crystallization; the solid-liquid mixed phase at the bottom of the continuous crystallizer is passed into...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com