Sodium bicarbonate crystal preparation equipment and process for preparing sodium bicarbonate crystals by utilizing same

The technology of a sodium bicarbonate and a process method is applied in the production equipment of sodium bicarbonate crystallization and the technical field of producing sodium bicarbonate crystallization by using the equipment, which can solve the problem that the crystal particles of sodium bicarbonate are fine and the cooler is easy to be scarred and fouled. , long and complicated processes, etc., to achieve the effect of not easy scarring, simple structure, and easy operation of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

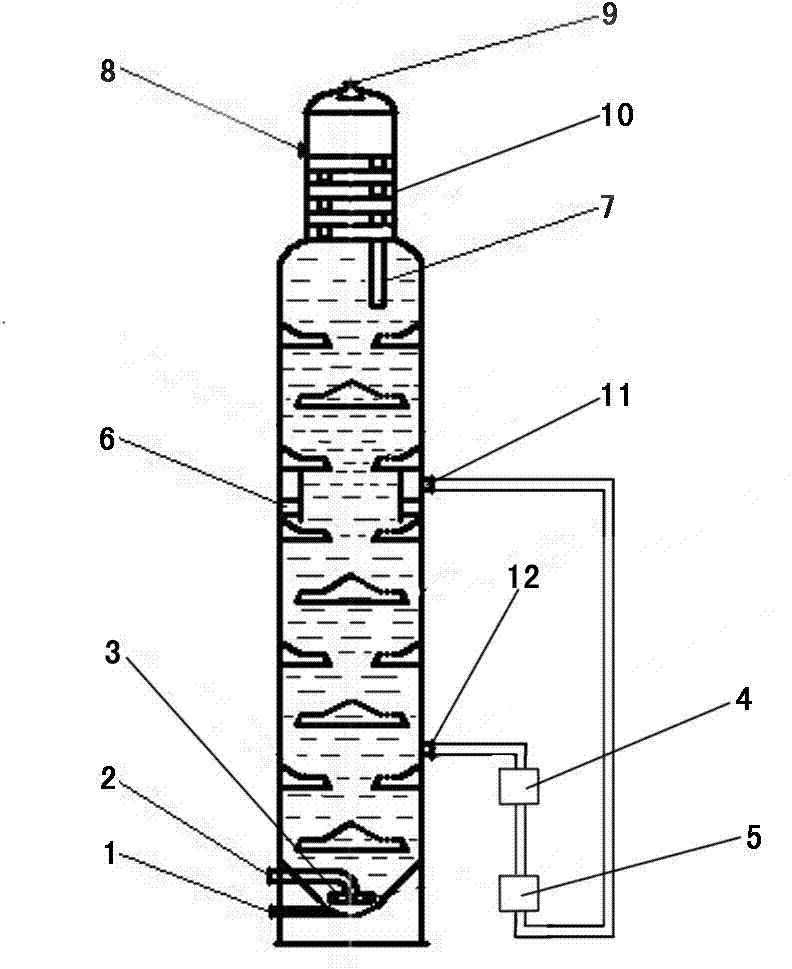

[0027] Such as figure 1 As shown, the total height of the carbonization tower used in the present invention is 27.87m, and the top of the tower is the tail gas absorption section 10 (5.77m high, 2.6m inner diameter), and the first reaction zone, the second reaction zone and the second reaction zone are successively below the tail gas absorption section 10. Three reaction zones (the total height of the three reaction zones is 22.1m, and the inner diameter is 4.6m).

[0028] The upper side wall of the tail gas absorption section 10 is provided with a liquid filling port 8 , and its top is provided with a carbon dioxide exhaust port 9 , and the tail gas absorption section 10 is connected with the first reaction zone by a downcomer 7 .

[0029] A magma separator 6 is installed on the tower body inner wall between the first reaction zone and the second reaction zone, and a liquid outlet 11 is provided on the tower body sidewall corresponding to the magma separator 6; A liquid retu...

Embodiment 2

[0032] Sodium bicarbonate crystallization preparation technological process is:

[0033] a) At the bottom of the carbonization tower, carbon dioxide (CO 2 , the concentration is 90~98%), and evenly distributed into the tower through the carbon dioxide distributor 3; at the top of the carbonization tower, the ammonia brine is supplied from the filling port 8 (temperature 25-30°C);

[0034] Ammonia brine is mixed with CO in tail gas absorption section 10 2 contact, pre-carbonization occurs, and a pre-carbonized liquid is obtained.

[0035] b) The pre-carbonization liquid descends into the first reaction zone and ascends CO 2 Carbonization reaction occurs in contact, and primary carbonization liquid is obtained, and sodium bicarbonate crystals start to separate out. After the sodium bicarbonate crystals are separated into the crystal slurry separator 6 with the primary carbonization liquid, the primary carbonization liquid is discharged from the liquid outlet 11 as the middle p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com