A system and method for treating coal gasification wastewater using microalgae

A technology for coal gasification wastewater and treatment methods, applied in chemical instruments and methods, biological water/sewage treatment, water/sludge/sewage treatment, etc., can solve energy consumption, high operating costs, long process flow, upstream phenol ammonia Problems such as the impact of recycling process, to achieve the effect of resource utilization and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] This embodiment is used to illustrate the system and method for treating coal gasification wastewater using microalgae provided by the present invention.

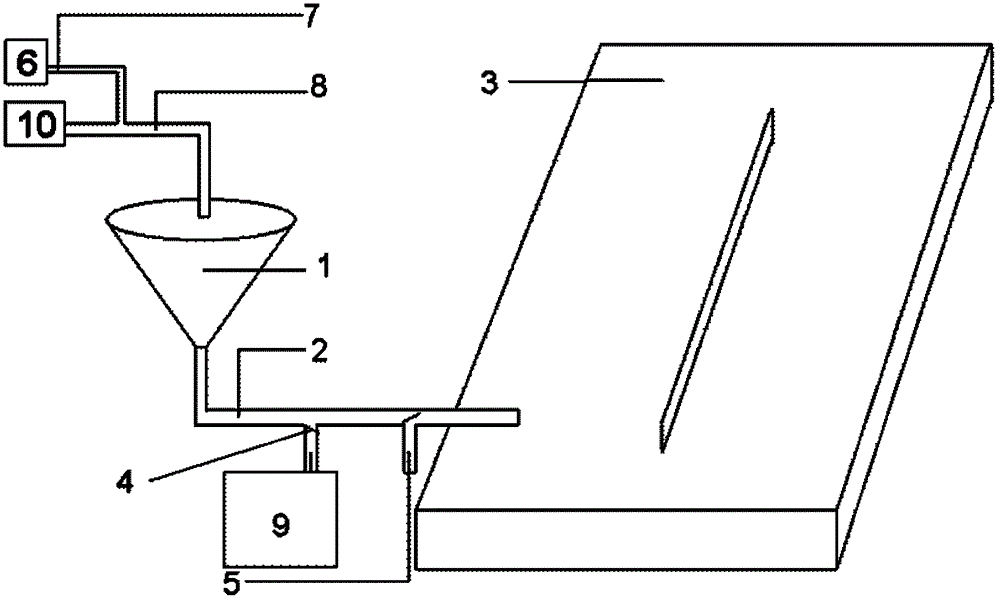

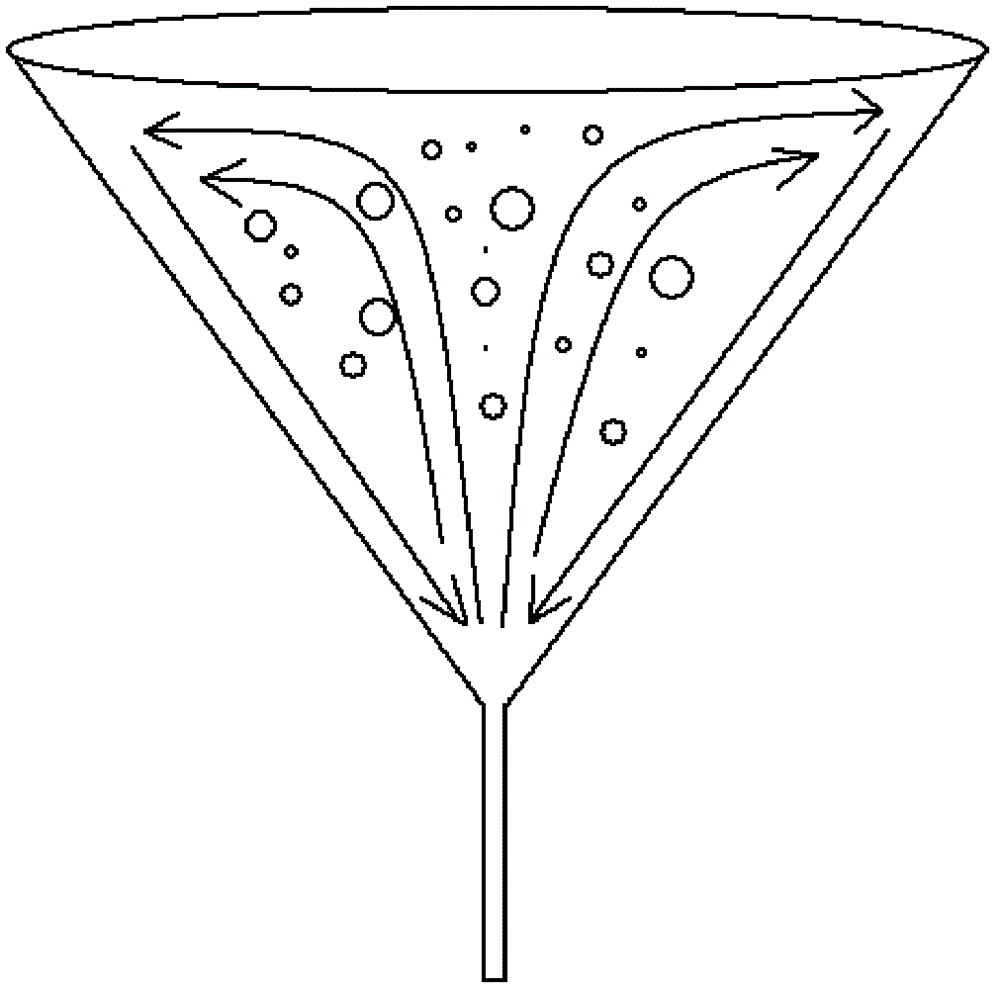

[0052] Such as figure 1 As shown, the system for treating coal gasification wastewater using microalgae provided by the present invention includes a microalgae cultivation device 1, a microalgae conveying device 2 and a coal gasification wastewater treatment device 3 provided with an inlet and an outlet. One end is connected to the outlet of the microalgae cultivation device 1, the outlet of the microalgae cultivation device 1 is set at the bottom of the microalgae cultivation device 1, the microalgae cultivation device 1 is funnel-shaped; the microalgae transportation The other end of the device 2 is in communication with the coal gasification wastewater treatment device 3. The microalgae conveying device 2 is also provided with an aeration valve 4 and a conveying control valve 5; the system also includes a connection w...

Embodiment 2-4

[0058] This embodiment is used to illustrate the system and method for treating coal gasification wastewater using microalgae provided by the present invention.

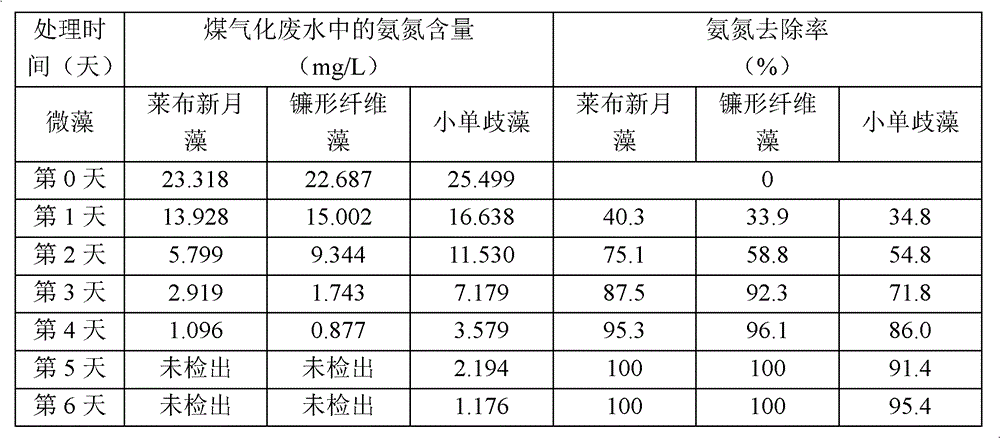

[0059] The coal gasification wastewater was treated according to the system and method of Example 1. The difference is that the microalgae used were Fusarium falciparum, Lebnoceria leucocephala and Monofidophyta. In addition, the COD value of the coal gasification wastewater to be treated is 187mg / L, the ammonia nitrogen content is 23-25.5mg / L, the content of heavy metals mercury, cadmium, chromium, arsenic, lead, and nickel are all below 0.9mg / L, and the pH value is Is 7.0.

[0060] The above-mentioned microalgae after continuous domestication and cultivation of coal gasification wastewater were respectively sent to the coal gasification wastewater treatment system provided by the present invention for rapid treatment of coal gasification wastewater, and the ammonia nitrogen content in the coal gasification wastewater wa...

Embodiment 5

[0065] This embodiment is used to illustrate the system and method for treating coal gasification wastewater using microalgae provided by the present invention.

[0066] The coal gasification wastewater was treated according to the method of Example 1. The difference is that the COD value of the wastewater to be treated is 300 mg / L, the ammonia nitrogen content is 50-65 mg / L, and the heavy metals mercury, cadmium, chromium, arsenic, lead, and nickel are respectively The content is below 1mg / L, and the pH is 6.5. Scenedesmus tetracera can remove more than 95% of ammonia nitrogen in coal gasification wastewater with an ammonia nitrogen content of 50-65mg / L within 7-8 days (on the first day, the ammonia removal rate is 30-35%, the second day, the ammonia nitrogen removal rate 45-50%, on the 3rd day, the ammonia removal rate is 65-70%, on the 4th day, the ammonia nitrogen removal rate is 75-82%, on the 5th day, the ammonia nitrogen removal rate is 85-88%, on the 6th day, the ammonia ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com