Method for preparing rapid external carbon source through cassava ethanol wastewater

A cassava alcohol and wastewater technology, which is applied in chemical instruments and methods, food industry wastewater treatment, biological water/sewage treatment, etc., can solve the problems of high effluent COD and unstable wastewater quality, and achieve the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

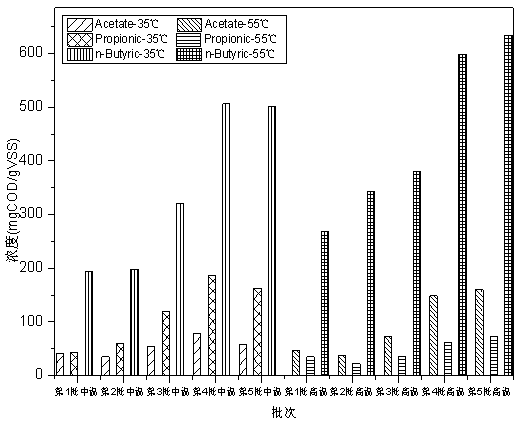

[0022] Using cassava alcohol wastewater as the substrate, take 270mL of the above substrate, inoculate 30mL of granular sludge, adjust the initial pH to 9, and place them in 35 o C and 55 o Under the condition of C, perform anaerobic fermentation for 48 hours, pour out 270 mL of the upper liquid after standing for half an hour, and add an equal volume of fresh cassava alcohol wastewater to adjust the initial pH=9, and the other fermentation conditions are the same as above, continue to ferment for 48 hours, and repeat this operation Five batches of experiments. Samples were taken for each batch of experiments to determine VFA concentration, SCOD, etc. The results showed that the total amount of VFA was slightly increased under high temperature conditions compared with medium temperature conditions, and the content of n-butyric acid and acetic acid was higher under high temperature conditions. When cassava alcohol wastewater is used as the substrate, it is recommended to choo...

Embodiment 2

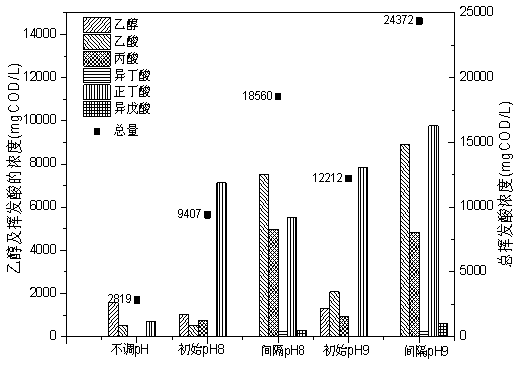

[0024] Take 360mL of cassava alcohol wastewater, inoculate 40mL of granular sludge, adjust the initial pH=8, place it in a water bath shaker with a rotation speed of 120r / min, and keep anaerobic fermentation at medium temperature for 3 days, and the content of volatile acid can reach 9.5gCOD / L , accounting for 27% of SCOD. Volatile acids are mainly composed of n-butyric acid, acetic acid and propionic acid, of which acetic acid is 512mg / L, propionic acid is 764mg / L, n-butyric acid is 7121mg / L, and the high-quality carbon source content (propionic acid + acetic acid content) reaches 24%.

Embodiment 3

[0026] According to the same matrix and inoculated sludge conditions of Example 2, adjust the initial fermentation pH=9, (35 under the medium temperature condition o C), after 3 days of anaerobic fermentation, the content of volatile acids can reach 12.2g / L, including 2084mg / L acetic acid, 958mg / L propionic acid, 7860mg / L n-butyric acid, high-quality carbon source (propionic acid + acetic acid content) Reached 46%. The total volatile acid content (calculated as COD) accounts for 38% of SCOD.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com