Ultraviolet light curing monomer and preparation method thereof, polymerizable composition, brightness enhancement film and backlight module

A polymer composition, ultraviolet light technology, applied in the direction of electric light source, organic chemistry, fixed lighting device, etc., can solve the problems of weak increase of LCD brightness, low refractive index of coating, etc., to achieve good brightness value, high refractive index efficient, easy to implement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0050] The preparation method of the polymerizable composition provided by the invention can be obtained directly by uniformly mixing the components in the composition. Preferably, in order to shorten the mixing time, mixing is preferably performed at 40-80°C.

[0051] The present invention also provides a brightness enhancing film, which is formed by curing the polymerizable composition provided by the present invention. The curing conditions are various curing conditions commonly used by those skilled in the art, for example, the polymerizable composition can be directly irradiated with ultraviolet light to be cured, and there is no special requirement in the present invention.

[0052] Finally, the present invention provides a backlight module, which includes a lamp tube, a light guide plate and a brightness enhancement film, wherein the brightness enhancement film is the brightness enhancement film provided by the present invention.

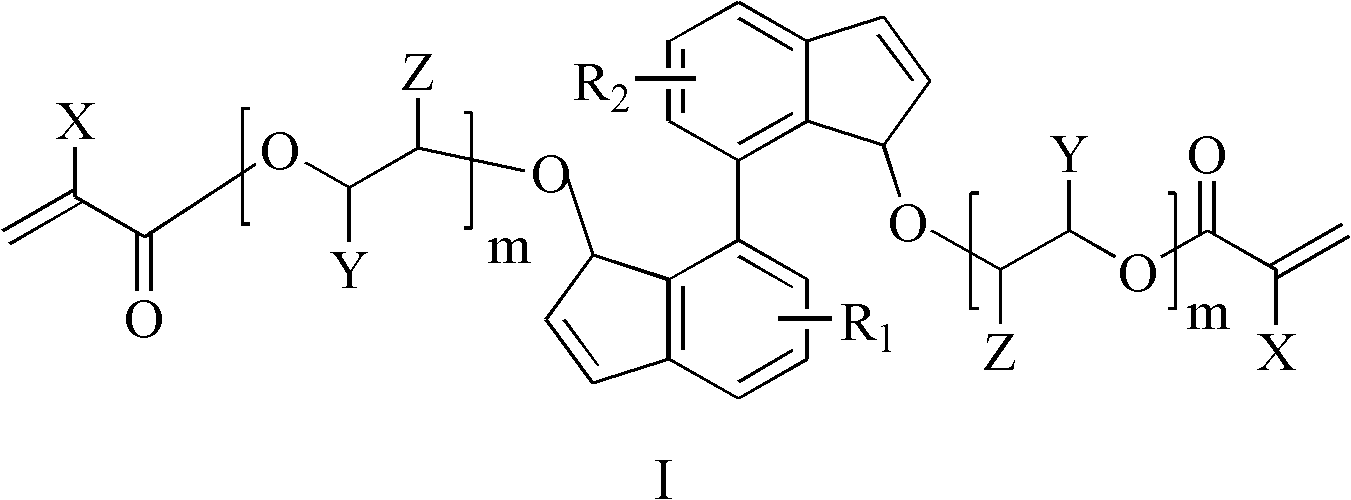

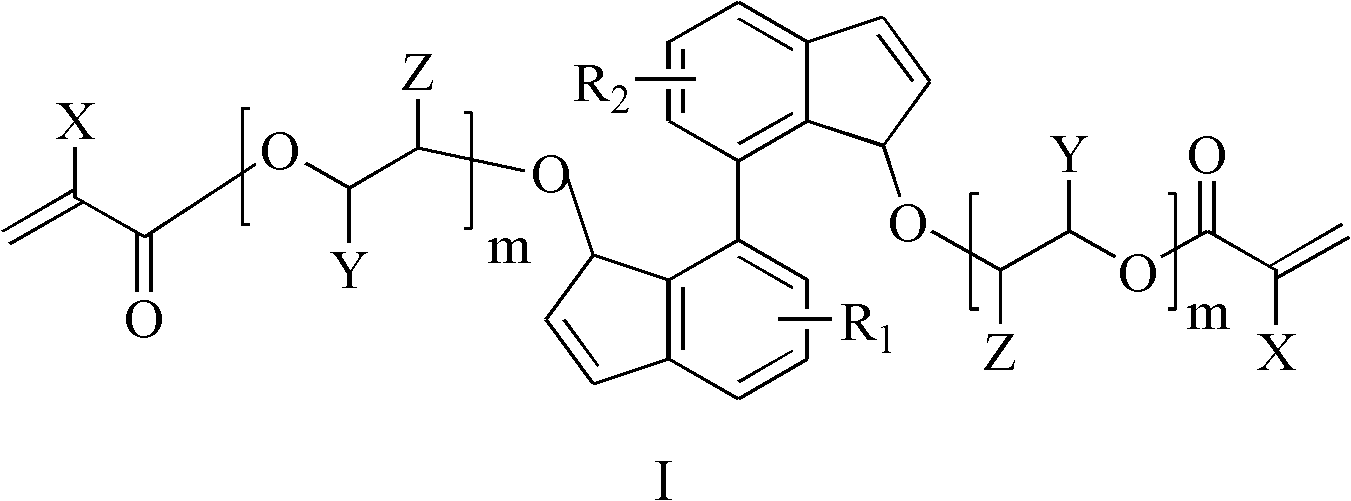

[0053] Wherein, the structures of the...

Embodiment 1

[0056] The raw materials used in this embodiment are as follows:

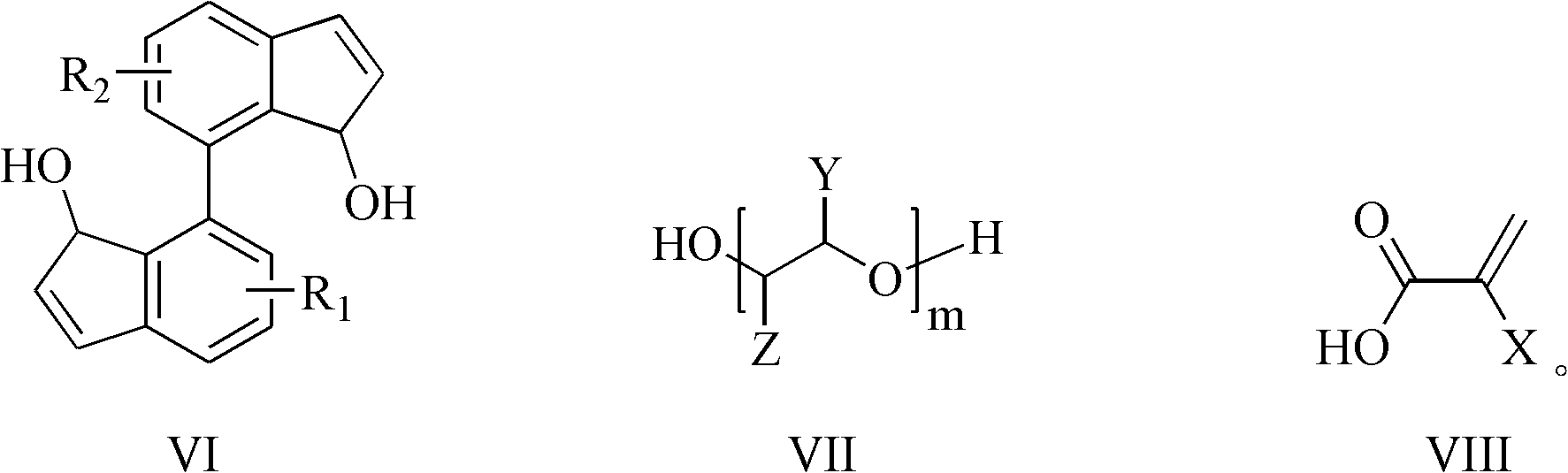

[0057] (a): compound shown in formula II; the compound of structure shown in IX and HO-CH 2 -CH 2 -OH is reacted in DMF to get the pre-product, then CH will be added 2 =CH-COOH, to obtain the compound shown in formula II.

[0058] (b): photoinitiator I184;

[0059] (c): crosslinking agent SR295;

[0060] (d): diluent o-phenylphenethoxyethyl acrylate;

[0061] (e): Additive: 15wt% SiO 2 +40wt% octadecyl dimethyl hydroxyethyl quaternary ammonium salt+15wt% leveling agent BYK-333+15wt% defoamer BYK-018+15wt% lubricant.

[0062] The above raw materials were mixed together according to the ratio in Table 1, and heated and stirred at 50° C. until a uniform and transparent colloidal polymerizable composition S1 was formed. The above-prepared colloidal polymerizable composition S1 is coated on a polyethylene terephthalate (PET) substrate, and cured by ultraviolet light to form a coating with a prism pattern, and...

Embodiment 2-4

[0064] Polymerizable compositions S2-S4 and brightness enhancing films S22-S44 were prepared using the same steps as in Example 1, except that the composition ratio of each component is shown in Table 1.

[0065] Table 1

[0066] Component

[0067] Note: In S2, (a) is the compound shown in formula III, and the compound shown in formula X is first combined with HO-CH 2 -CH 2 -OH reacts with CH 2 =CH-COOH reaction is made; In S3, (a) is the compound shown in formula IV, is earlier and HO-CH by the compound shown in formula IX 2 -CH(CH 3 )-OH reacts with CH 2 =C(CH 3 )-COOH reaction and make; In S4, (a) is the compound shown in the formula V, by the compound shown in the formula XI first with HO-CH (CH 3 )-CH(CH 3 )-OH reacts with CH 2 = CH-COOH reaction in the system.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com