High-strength and high-toughness polyamide/polyester alloy, preparation method and application thereof

A technology of polyester alloy and polyamide, applied in the field of modified plastics, can solve the problems that the alloy does not have practical use value and cannot meet the application requirements of engineering grade, and achieves the effects of high toughness, improved compatibility and increased strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

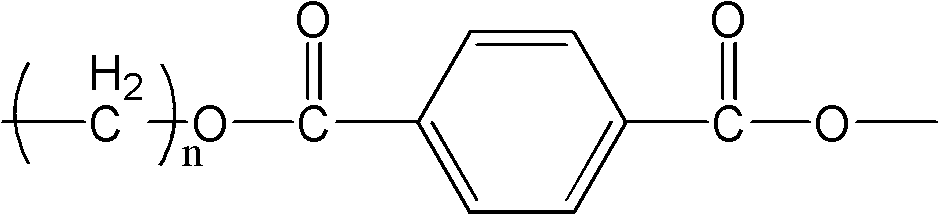

Method used

Image

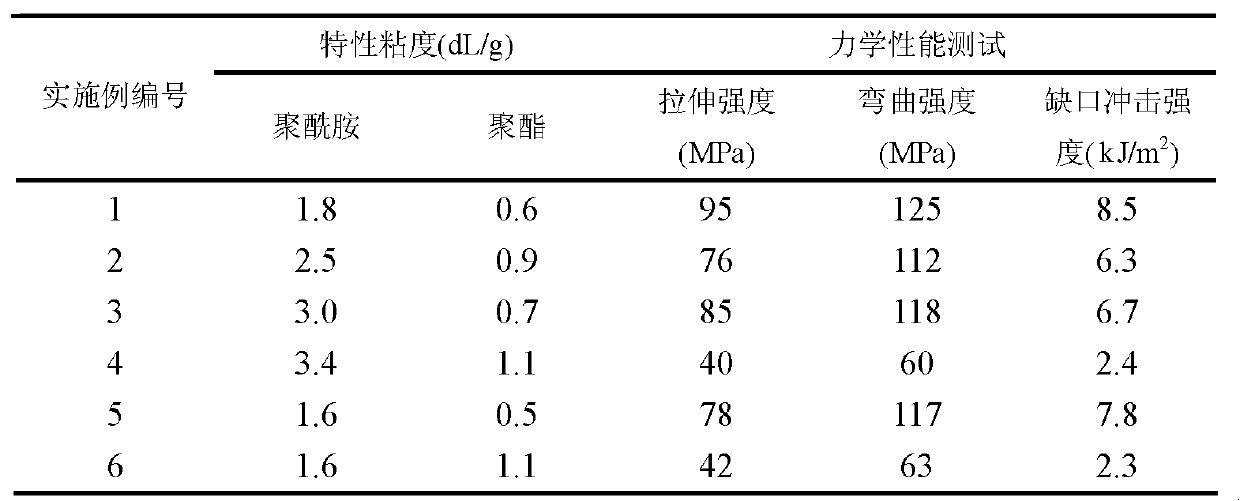

Examples

Embodiment 1

[0051] A high-strength, high-toughness polyamide / polyester alloy prepared by the following steps:

[0052] (1) PA6 and PET are dried respectively;

[0053] (2) Dry PA6 (95wt%, viscosity 1.8dL / g) and PET (3%, viscosity 0.6dL / g) with sodium benzenesulfonate (0.5wt%), maleic anhydride grafted polypropylene (0.5wt%), auxiliary agent (made up of antioxidant 1098, lubricant polyethylene wax and nucleating agent superfine talcum powder) (1wt%) is added to the extruder by weight loss metering after mixing by high-speed mixer , Extruded and granulated to obtain a high-strength, high-toughness polyamide / polyester alloy. The settings of the twin-screw extruder are as follows: the temperature of the first zone of the twin-screw extruder is 120-140°C, the temperature of the second zone is 260-270°C, the temperature of the third zone is 240-250°C, the temperature of the fourth zone is 240-250°C, and the temperature of the fifth zone The temperature is 240-250°C, the six-zone temperature i...

Embodiment 2

[0056] A high-strength, high-toughness polyamide / polyester alloy prepared by the following steps:

[0057] (1) PA12 and PBT are dried respectively;

[0058] (2) PA12 after drying (60wt%, viscosity is 2.5dL / g) and PBT (35wt%, viscosity is 0.9dL / g) and potassium benzenesulfonate (2wt%), maleic anhydride grafted polyethylene ( 2wt%), auxiliary agent (consisting of antioxidant 1098 and lubricant polyethylene wax) (1wt%) is mixed by a high-speed mixer and then added to the extruder by weight loss metering, extruded and granulated to obtain high strength, High toughness polyamide / polyester alloy. The settings of the twin-screw extruder are as follows: the temperature of the first zone of the twin-screw extruder is 120-140°C, the temperature of the second zone is 260-270°C, the temperature of the third zone is 240-250°C, the temperature of the fourth zone is 240-250°C, and the temperature of the fifth zone The temperature is 240-250°C, the six-zone temperature is 260-270°C, the head ...

Embodiment 3

[0061] A high-strength, high-toughness polyamide / polyester alloy prepared by the following steps:

[0062] (1) PA66 and PET are dried separately;

[0063] (2) PA66 after drying (42wt%, viscosity is 3.0dL / g) and PET (42wt%, viscosity is 0.7dL / g) and polyester ionomer (Du Pont Company, Surlyn 9320) (7wt%), Maleic anhydride grafted polystyrene (8wt%), auxiliary agent (composed of antioxidant 1098, lubricant polyethylene wax and nucleating agent ultra-fine talcum powder) (1wt%) passed through the weight loss formula after mixing by high-speed mixer The metering scale is added to the extruder, extruded and granulated to obtain a high-strength, high-toughness polyamide / polyester alloy. The settings of the twin-screw extruder are as follows: the temperature of the first zone of the twin-screw extruder is 120-140°C, the temperature of the second zone is 260-270°C, the temperature of the third zone is 240-250°C, the temperature of the fourth zone is 240-250°C, and the temperature of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

| Intrinsic viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com