Method for producing gasoline and diesel by directly hydrogenating medium and low temperature coal tar

A low-temperature coal tar and coal tar technology, applied in the fields of oil refining, petrochemical industry, and coal chemical industry, can solve the problems of large investment and high operating pressure, and achieve the effects of reducing capital construction investment, reducing operating pressure and long service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

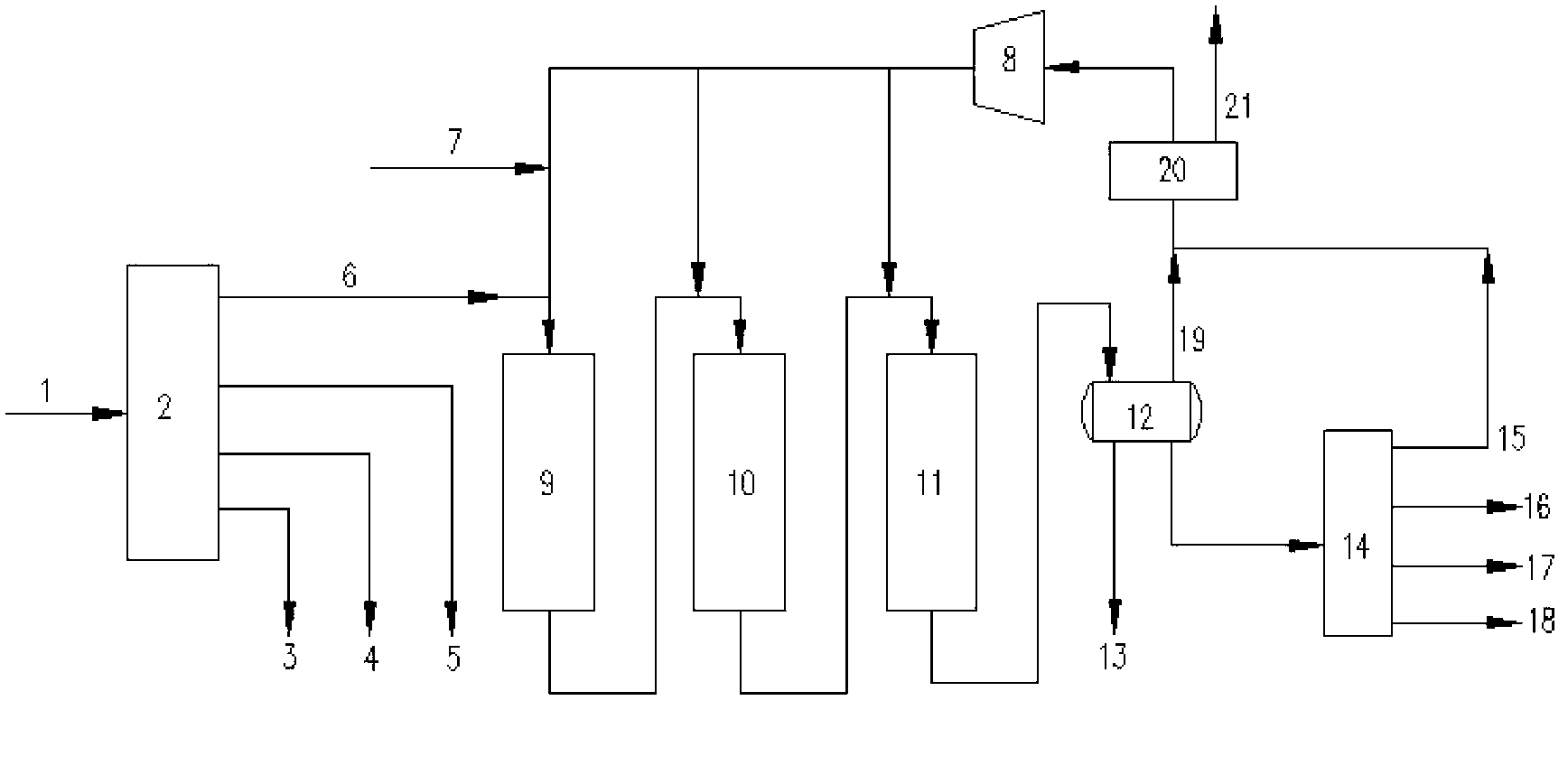

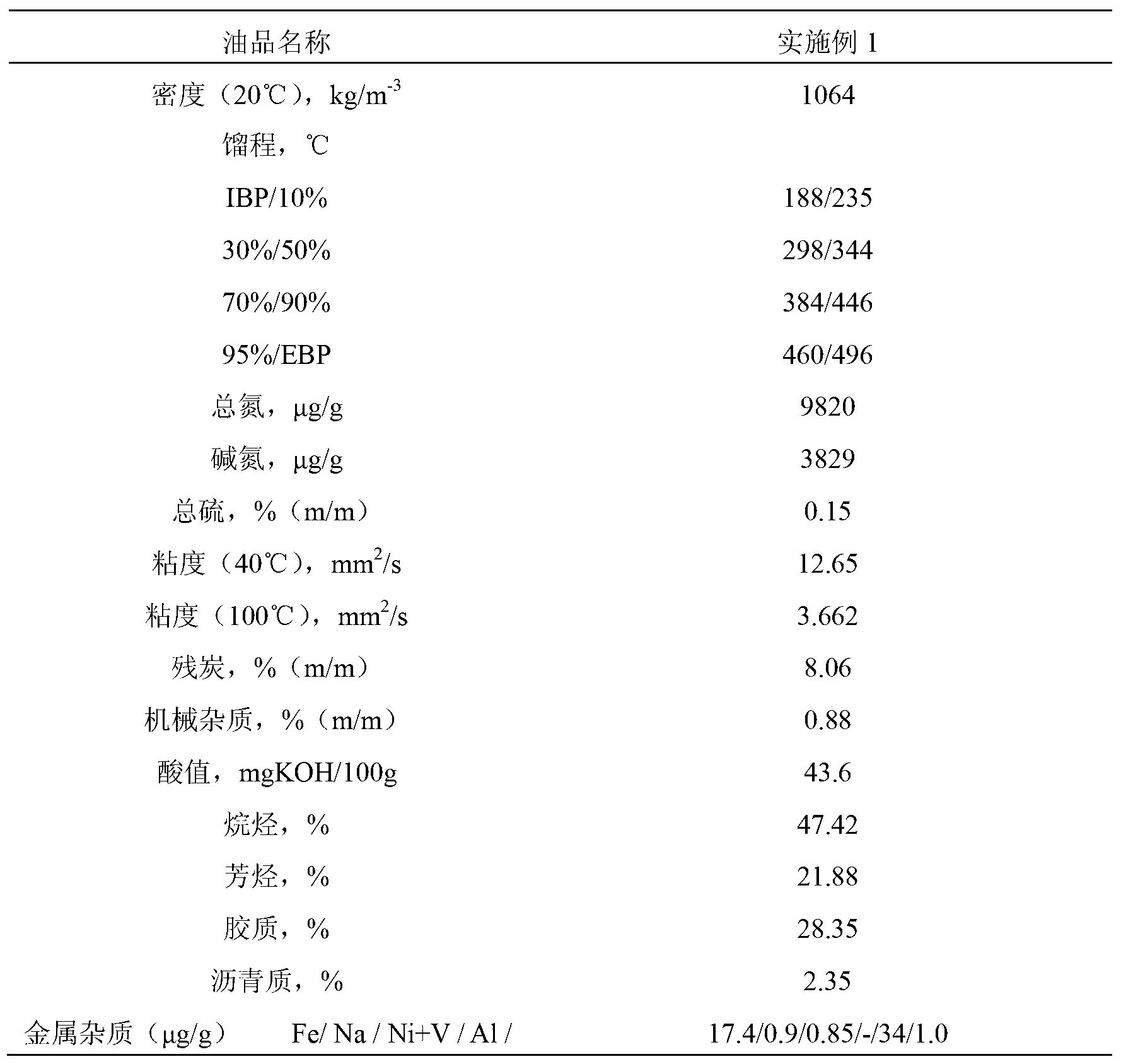

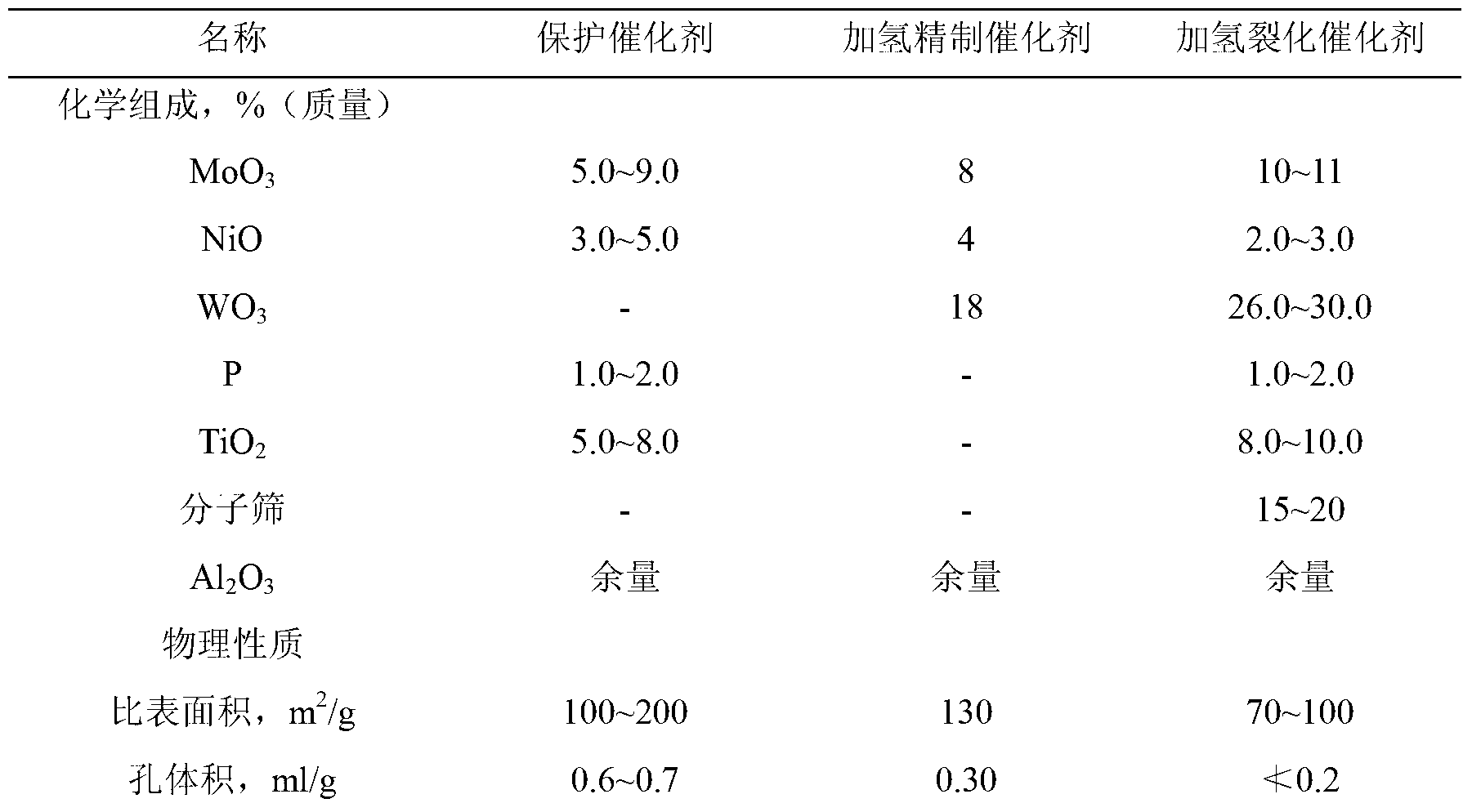

[0046] Medium and low temperature coal tar adopts the combination of raw material pretreatment-hydrofinishing-PSA purification to produce clean gasoline and diesel products. The medium and low temperature coal tar first passes through the pretreatment unit to remove the oily wastewater and waste residue in the material, and the remaining liquid phase components are separated into heavy oil and hydrogenated raw material oil (final boiling point <480°C). The heavy oil is sent to the tank farm, and the hydrogenated raw oil is sent to the hydrofining unit. In the presence of hydrogen, the raw material oil for hydrogenation enters the protective reactor equipped with corresponding catalysts, the hydrofinishing reaction unit and the hydrocracking reaction unit for reaction, and the reaction product is sent to the three-phase high-pressure separation tank (that is, the high-separation tank 12), the gas phase in the tank is mixed with the dry gas produced by the subsequent separation ...

Embodiment 2

[0048] The raw materials, process flow and corresponding catalyst used are the same as in Example 1. The difference from Example 1 is the selected process conditions. The reaction process conditions are shown in Table 3, the properties of gasoline are shown in Table 4, and the properties of diesel oil are shown in Table 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com