Preparation method of recombinant human insulin

A technology of recombinant human insulin and human insulin, which is applied in fermentation and other directions, can solve the problems of low transpeptide rate, instability, high cost, etc., and achieve the effect of reducing dosage, reducing cost and reducing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

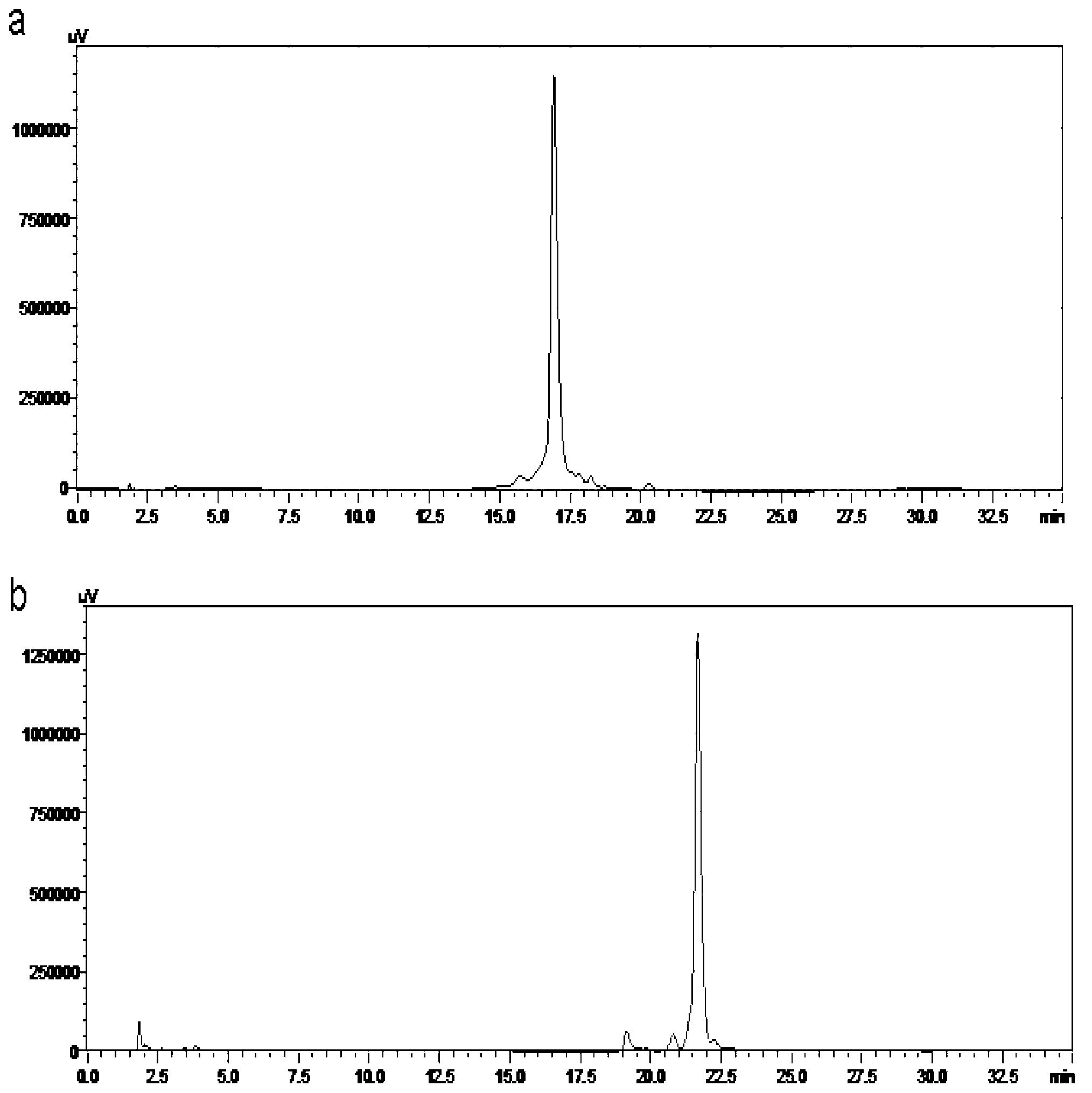

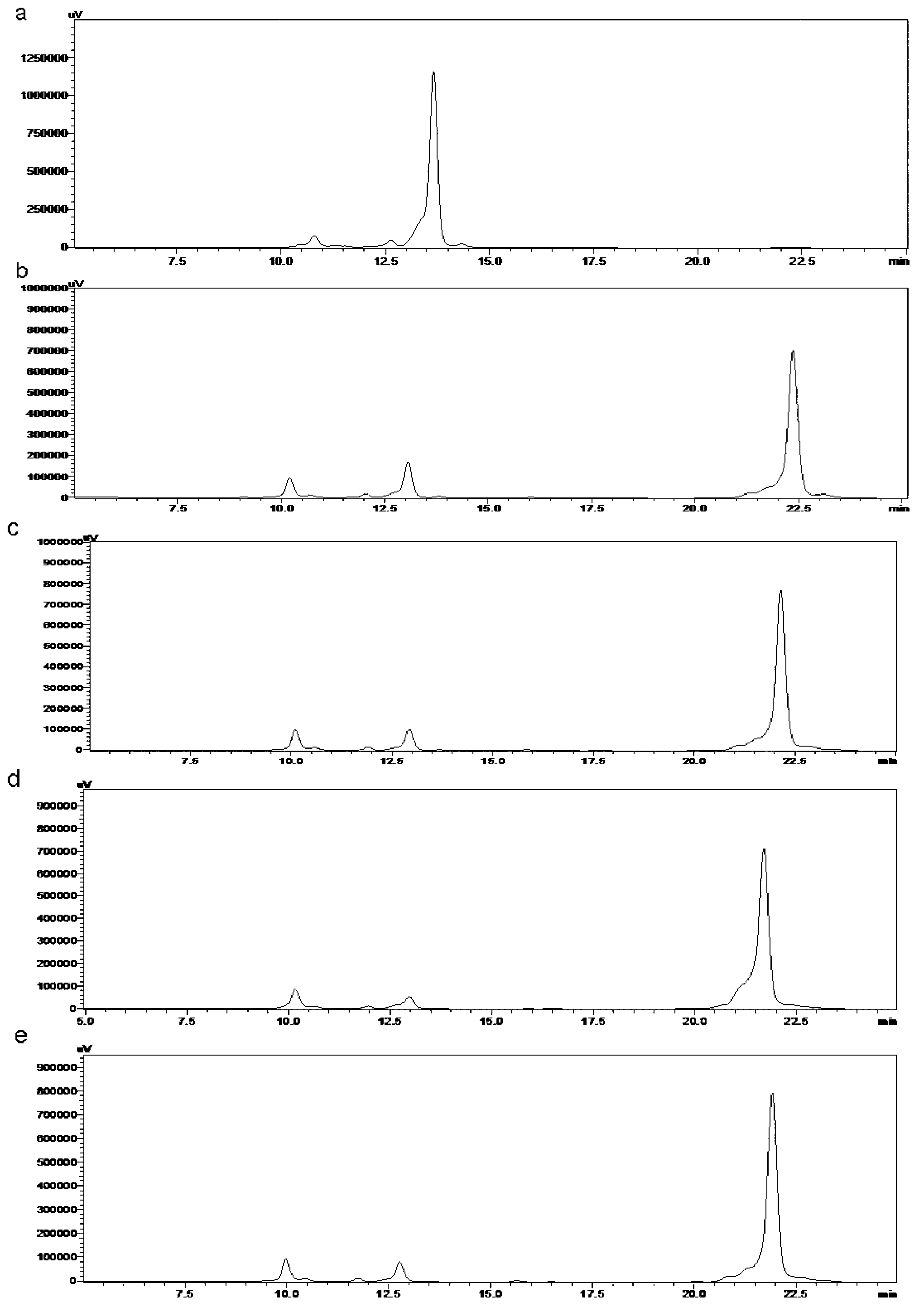

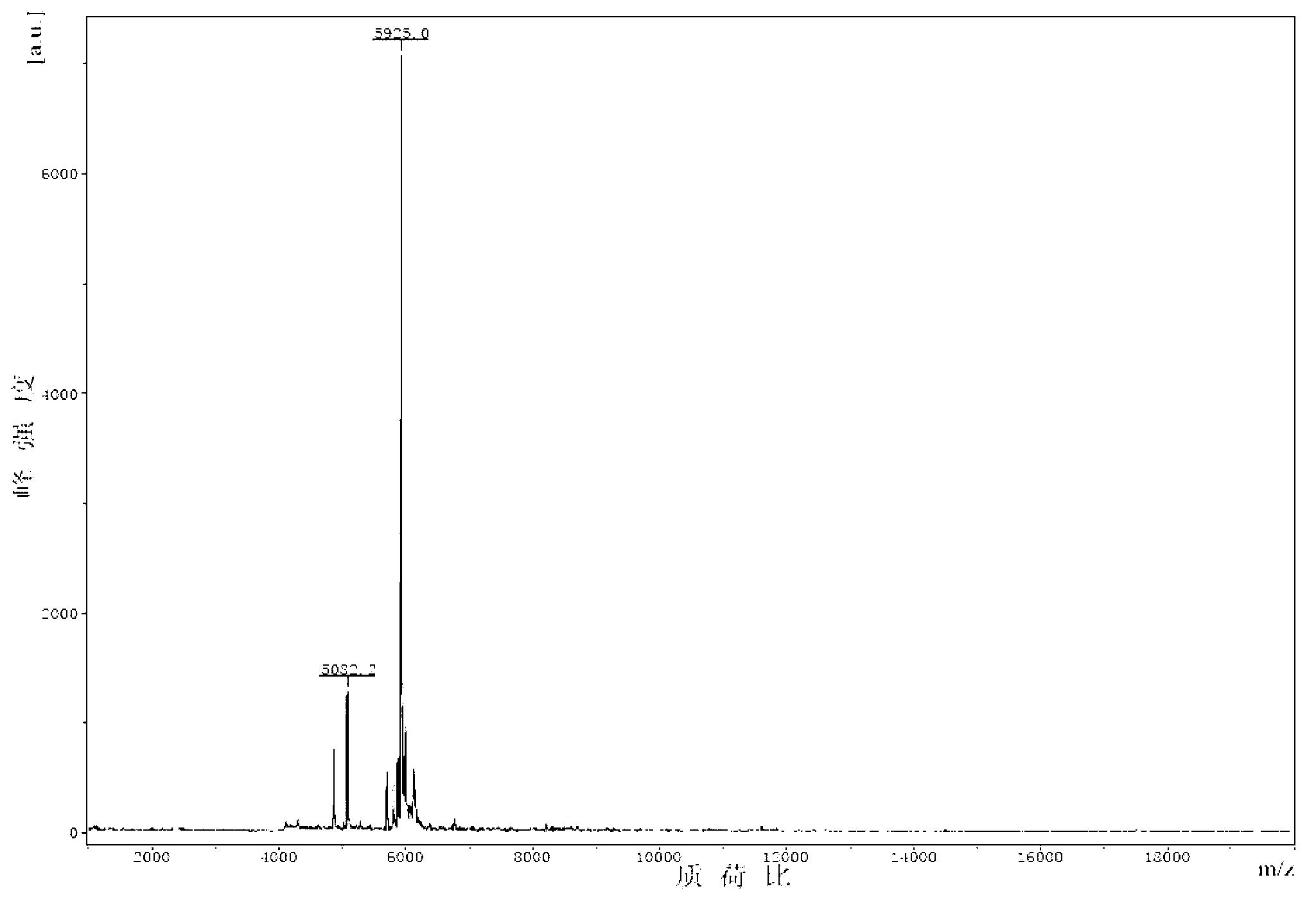

[0048] (1) desB 30 Preparation of human insulin water-containing powder: recombinant human insulin precursor secreted and expressed by Pichia pastoris, purified by macroporous adsorption resin (references: Gao Jiankun, Cai Shaoxi, Fan Kai, etc., containing short C-peptide human proinsulin analog desB 30 Expression and purification in Pichia pastoris, Progress in Biochemistry and Biophysics, 2008, 35 (1): 63-68) The sample solution was diluted 2 times and then reversed-phase purified, gradient eluted with isopropanol, Obtain the recombinant human insulin precursor aqueous solution containing isopropanol (concentration is 24% by volume) (HPLC detection spectrum is as follows: figure 1 As shown in a), adjust the pH value to 8.5 with 5M ammonia water. Trypsin was added according to the mass ratio of trypsin to recombinant human insulin precursor 1:300, and digested at 25°C for 3 hours to obtain a digested solution. The recombinant digested rate was 97.55% by HPLC (the HPLC detect...

Embodiment 2

[0053] (1) desB 30 Preparation of aqueous human insulin powder: Dilute the recombinant human insulin precursor aqueous solution in Example 1 to a concentration of isopropanol of 10% by volume, and adjust the pH to 9 with 5M ammonia water. Add trypsin according to the mass ratio of trypsin to recombinant human insulin precursor 1:400, and digest at 25°C for 5 hours. The enzyme cleavage rate of recombinant human insulin precursor was detected to be 95.31%. Add zinc chloride according to the molar ratio of human insulin precursor to zinc chloride 1:1.5, adjust the pH value to 5.8 with 3M phosphoric acid solution, place it overnight at 4-8°C, and filter it with a 300-mesh filter membrane to obtain desB 30 Human insulin water-containing powder, and measure the water content and content.

[0054] (2) with desB 30 The reaction concentration of human insulin is 13.4mM for transpeptidation reaction to obtain recombinant human insulin ester: dissolve desB with dimethyl sulfoxide 30 ...

Embodiment 3

[0057] (1) desB 30 Preparation of human insulin water-containing powder: the recombinant human insulin precursor in Example 1 was eluted with ethanol during reverse-phase purification, the eluate was diluted to an ethanol concentration of 30% by volume, and the pH value was adjusted to 8.5 with 5M ammonia water. Add trypsin according to the mass ratio of trypsin to recombinant human insulin precursor 1:300, and digest at 25°C for 6 hours. The enzyme cleavage rate of recombinant human insulin precursor was detected to be 96.07%. Add zinc chloride according to the molar ratio of human insulin precursor to zinc chloride 1:0.5, adjust the pH to 5.80 with 3M phosphoric acid, place it overnight at 4-8°C, and centrifuge at 8000g to obtain desB 30 Human insulin aqueous powder. Determination of its moisture and content.

[0058] (2) with desB 30 The reaction concentration of human insulin is 12.1mM for transpeptidation reaction to obtain recombinant human insulin ester: dissolve de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com