Metallographic test sample preparation method of aluminum-based ceramic mould core and silicon-based ceramic mould core

A technology of metallographic samples and aluminum-based ceramics, applied in the field of test parameters, can solve the problems of high brittleness of ceramic materials, and achieve the effect of avoiding uncontrollability and strong operability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

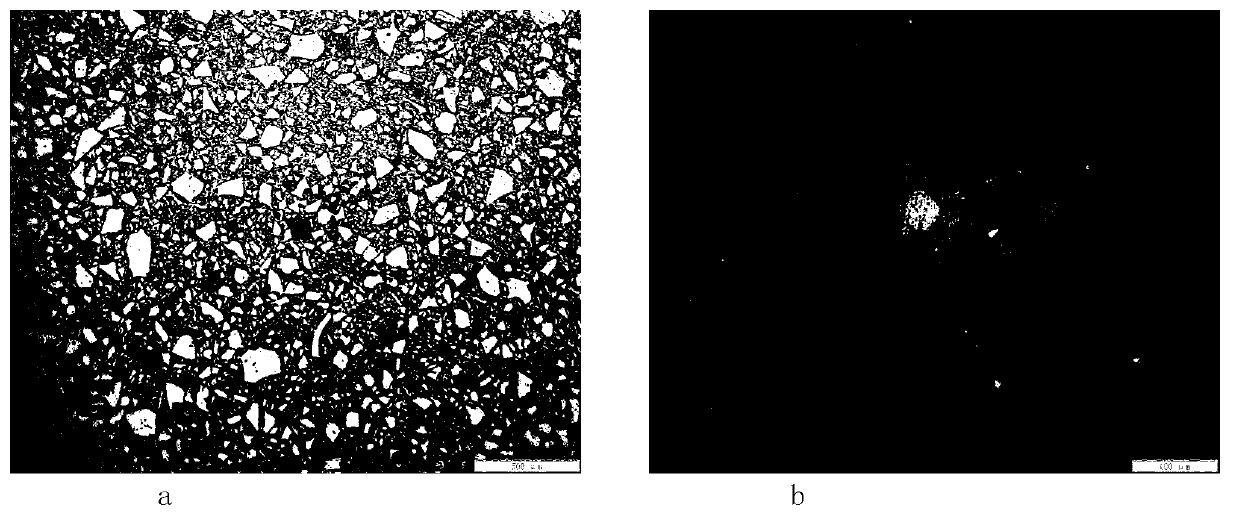

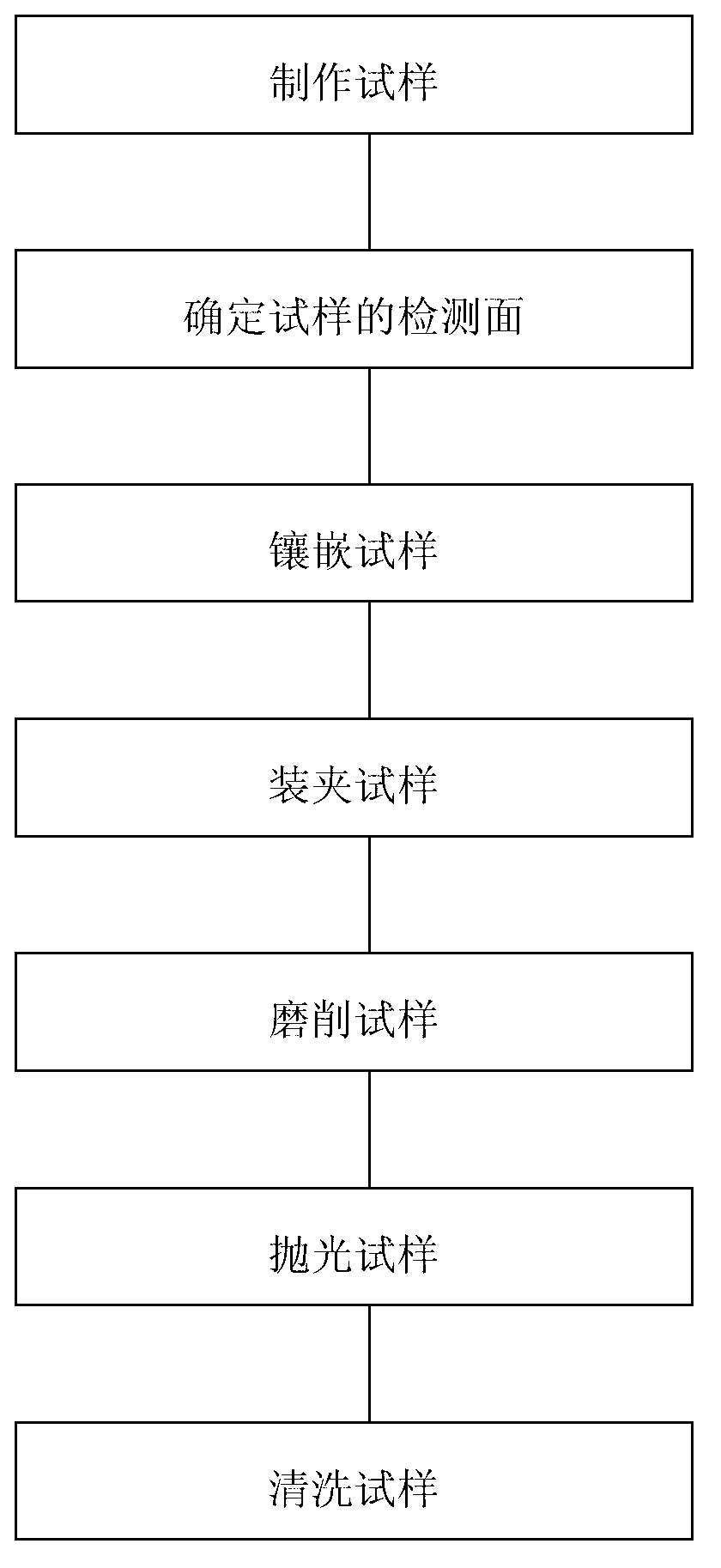

[0021] This embodiment is a method for preparing a ceramic material into a microstructure sample. The ceramic material is an aluminum-based ceramic core for the turbine blade DZ125 of an aero-engine. The concrete process of this embodiment is:

[0022] The first step: making samples. A plurality of samples are cut from the parts to be observed of the aluminum-based ceramic core material and marked respectively to obtain a group of samples. In this embodiment, the number of samples is five.

[0023] Step 2: Determine the detection surface of the sample. The relatively flat surface of the two surfaces of each sample is taken as the detection surface of the sample.

[0024] The third step: mount the sample. Put each sample into each metallographic sample inlay mold. According to conventional method, with epoxy resin: dibutyl phthalate: ethylenediamine preparation mounting agent; Described epoxy resin: dibutyl phthalate: the mass ratio of ethylenediamine is 100:18: 10. Pou...

Embodiment 2

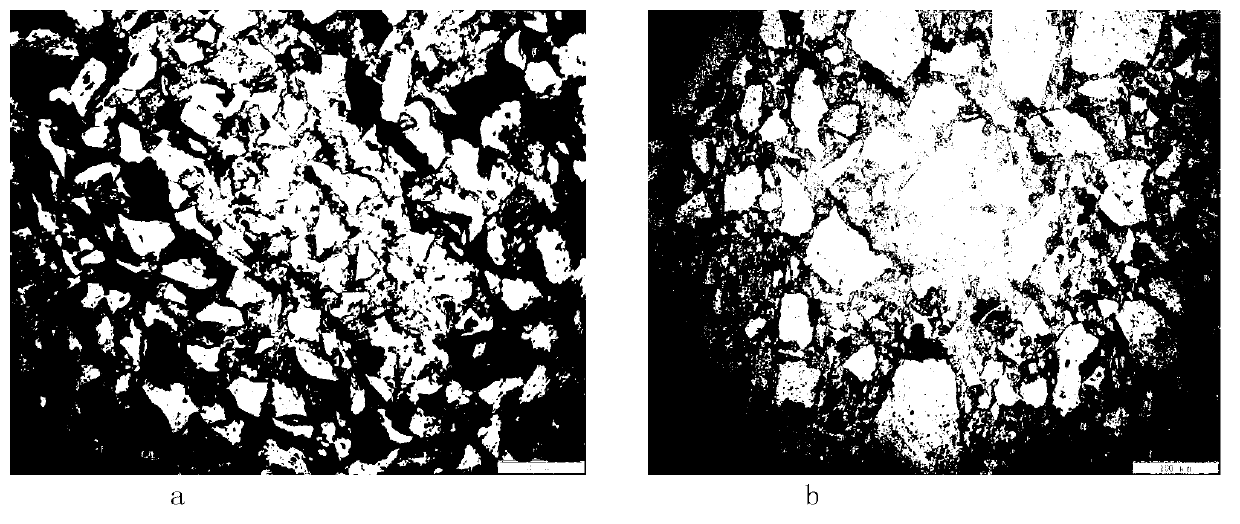

[0034] This embodiment is a method for preparing a ceramic material into a microstructure sample. The ceramic material is a silicon-based ceramic core for the aeroengine turbine blade DD6. The concrete process of this embodiment is:

[0035] The first step: making samples. A plurality of samples are cut from the parts to be observed of the silicon-based ceramic core material and marked respectively to obtain a group of samples. In this embodiment, the number of samples is 5

[0036] Step 2: Determine the detection surface of the sample. The relatively flat surface of the two surfaces of each sample is taken as the detection surface of the sample.

[0037]The third step: mount the sample. Put each sample into each metallographic sample inlay mold. According to conventional method, with epoxy resin: dibutyl phthalate: ethylenediamine preparation mounting agent; Described epoxy resin: dibutyl phthalate: the mass ratio of ethylenediamine is 100:18: 10. Pour the obtained mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com