Method for detecting subsurface defects of optical glass

A subsurface defect, optical glass technology, applied in the direction of optical testing flaws/defects, etc., can solve the problems of complex operation, high cost, special requirements for sample morphology, etc., and achieve simple experimental steps, low cost, and fast detection speed. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

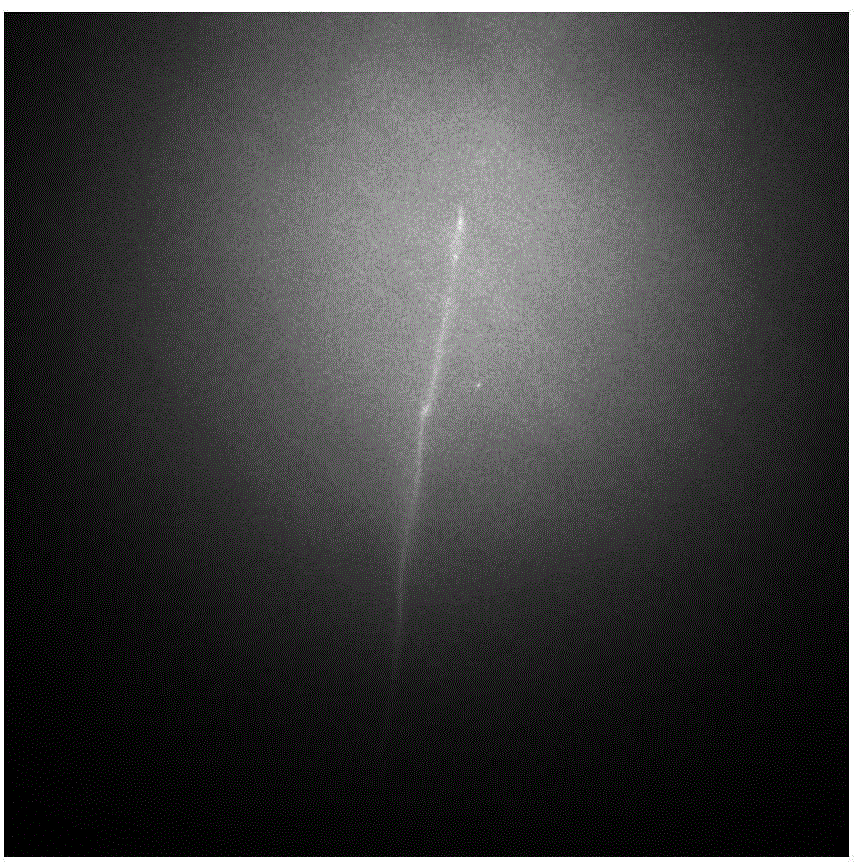

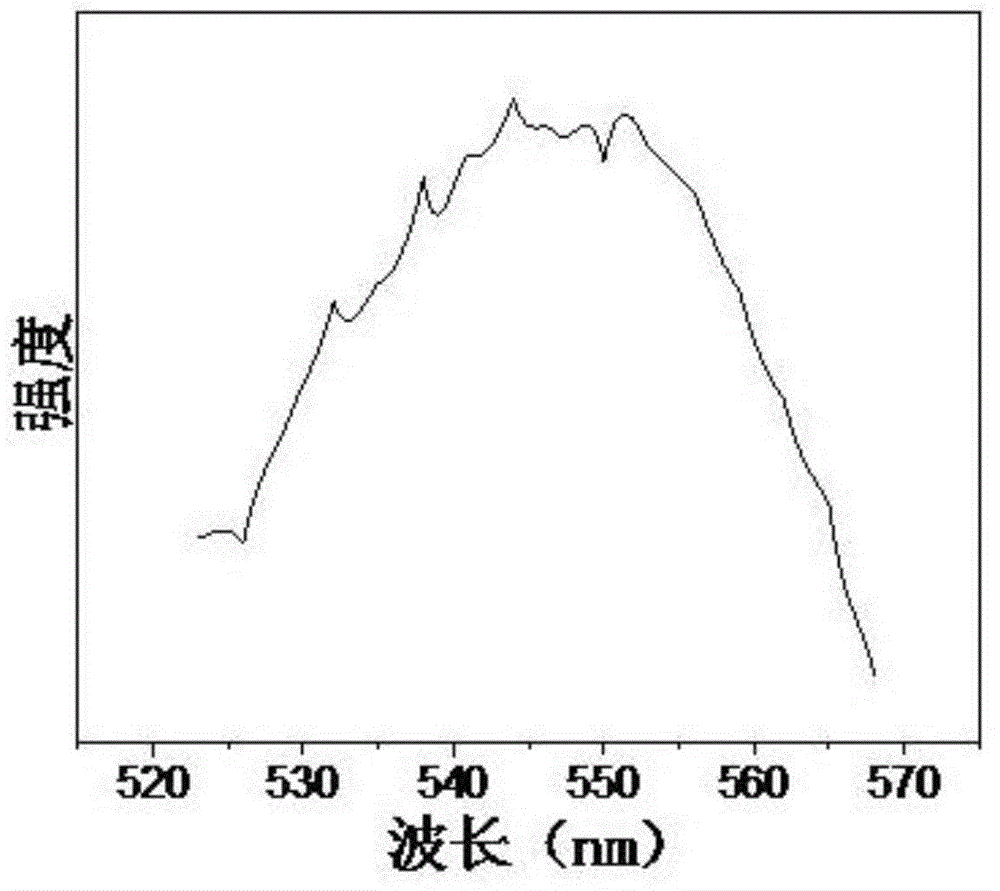

[0036] The implementation steps of the inventive method are as follows:

[0037] 1) Evenly mix glycerol and deionized water with a volume ratio of 1:4 to form a mixed solution.

[0038] 2) Add rhodamine 6G to the mixture of glycerol and water to obtain a buffer solution. The concentration of rhodamine 6G in the buffer is 1 × 10 -3 moL.

[0039] 3) Take 100ml of the prepared buffer solution, add 10g of granular abrasives to obtain an abrasive, set the rotation speed of the grinding disc at 50r / min, and use this abrasive to grind N3135 neodymium-doped phosphate laser glass for 30s;

[0040] 4) Take 100ml of the prepared buffer solution, add 1g of polishing powder to obtain a polishing solution, set the rotation speed of the grinding disc at 220r / min, and use the polishing solution to polish N3135 neodymium-doped phosphate glass for 10 minutes.

[0041] 5) Clean the polished N3135 neodymium-doped phosphate glass with ultrasonic alcohol for 5 minutes, and wipe the sample dry wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com