Forming method of large-scale metal storage tank with high bonding strength inner wall anticorrosive layer

A technology of bonding strength and anti-corrosion layer, applied in the field of plastic product molding and processing, can solve the problems of insufficient bonding force between polyethylene and steel substrate, delamination of inner and outer layers, peeling, etc., so as to solve the problem of insufficient bonding strength and enhance chemical bonding. Strength, bond strength and yield improvement effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

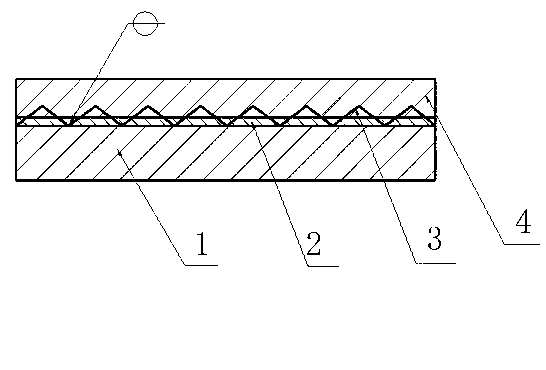

[0030] Such as figure 1 shown.

[0031] figure 1 The internal volume of the metal tank is 200 cubic meters, and its processing method is as follows:

[0032] First, prepare the silane solution for subsequent use, and the preparation method of the silane solution is as follows:

[0033] (1) Add methanol and deionized water to a magnetic stirrer to form a hydrolysis mixed solvent; the presence of methanol will prolong the hydrolysis time of KH 560 and make it more stable; the volume percentage of methanol and deionized water is: 25- 35%: 65-75%.

[0034] (2) Slowly add KH 560 silane to the mixed solvent for hydrolysis, dropwise add 30-40% by mass (optimally 35%) acetic acid solution to adjust the pH to 4.5 to 5.5, and the volume concentration of silane to be 4-6% (optimally 5%);

[0035] (3) Stir continuously until the solution is transparent and uniform;

[0036] (4) Place the solution at room temperature for hydrolysis, and after about 48 hours, the KH 560 solution req...

Embodiment 2

[0050] A method for forming a large metal storage tank with a high bonding strength inner wall anticorrosion layer, comprising the following steps:

[0051] 1. The step of roughening the surface of the steel substrate;

[0052] In this step, the 07MnCrMoVR stainless steel plate (with a size of 2900mm*1500mm*8mm) used for producing the outer wall of the storage tank is subjected to roughening treatment. The equipment used for laser texturing is the "Lance 3500" laser produced by Huagong Hengxin Laser Company. After the surface of the steel substrate is roughened by laser, a micro-concave-convex structure with a diameter of 200um, 20 points / mm2, and a roughness of 0.8-1.5um is formed, which increases the roughness of the surface of the steel substrate 1, and then aggregates The bonded contact area between the vinyl coating layer 4 and the steel substrate 1 increases, increasing the bonding strength.

[0053] 2. Use a cleaning agent to clean the surface of the steel substrate 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface roughness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com