Method for recovering ammonium nitrate from radioactive waste liquid

A technology of radioactive waste liquid and ammonium nitrate, which is applied in the direction of ammonium nitrate, etc., to achieve the effect of compact process flow, easy operation and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

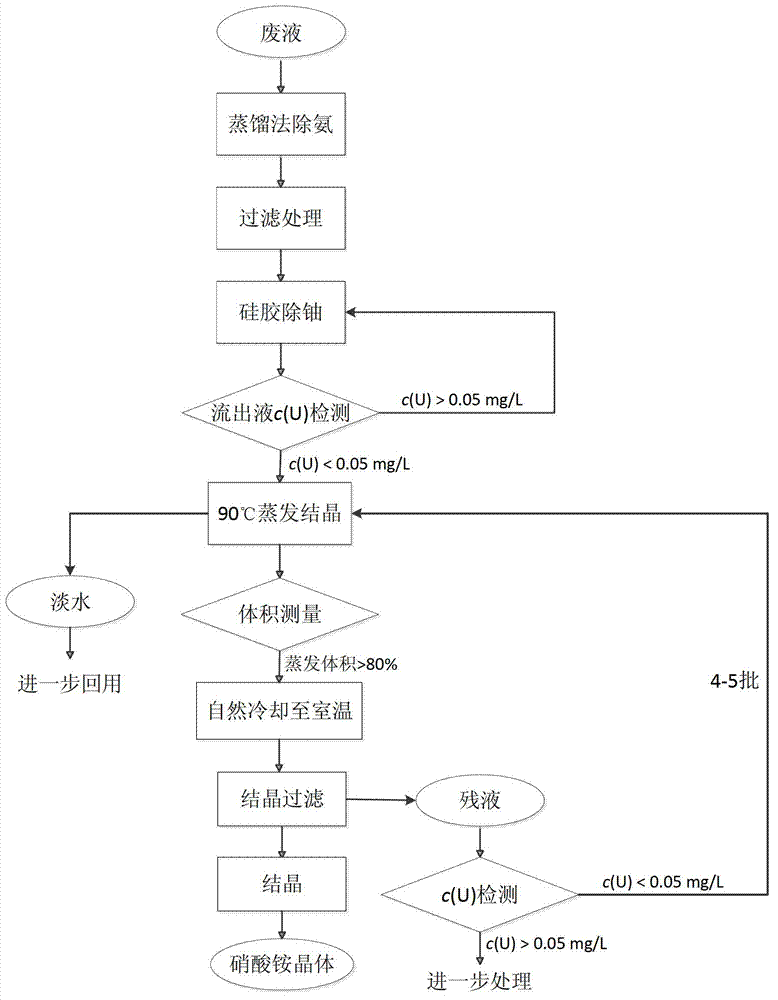

[0029] During the production of a batch of spherical fuel elements, 25 liters of process waste liquid needs to be treated. The ammonia concentration in the waste liquid is 10g / L, the uranium content is 3.7mg / L, and the COD value of high molecular organic matter is 1.0×10 4 , the concentration of ammonium nitrate is 68g / L. In order to realize the recovery of ammonium nitrate in the waste liquid, the adopted scheme is as follows: firstly, the waste liquid is distilled to remove ammonia, and then the solid impurities and high-molecular organic matter in the waste water are removed by filtration, and then the uranium is removed by silica gel adsorption. Finally, ammonium nitrate is recovered by evaporation and crystallization. see process figure 1 .

[0030] The waste liquid of this process is left standing in the waste liquid tank. After the solid matter in the waste liquid is precipitated, the supernatant liquid is sent to the heat exchanger with a pump for distillation to re...

Embodiment 2

[0036] The ammonia concentration in the waste liquid to be treated is 10g / L, the uranium content is 4.2mg / L, and the COD value of high molecular organic matter is 3.0×10 4 , the concentration of ammonium nitrate is 59g / L.

[0037] The waste liquid of this process is left standing in the waste liquid tank. After the solid matter in the waste liquid is precipitated, the supernatant liquid is sent to the heat exchanger with a pump, and the ammonia is removed by distillation. The ammonia mass concentration in the waste liquid after the ammonia removal is reduced to 0.2 %.

[0038] The waste liquid after ammonia removal is pressurized to 0.35MPa by a pump, and passes through activated carbon, microfiltration membrane (pore size: Φ10μm) and ultrafiltration membrane (pore size: Φ0.5μm) in sequence to remove solid particles with a particle size of micron in the waste liquid and some macromolecules. The COD value in the treated waste liquid is 1.1×10 2 , The removal rate of polymeri...

Embodiment 3

[0042] The concentration of ammonia in the waste liquid to be treated is 10g / L, the content of uranium is 10mg / L, and the COD value of high molecular organic matter is 3.0×10 4 , the concentration of ammonium nitrate is 70g / L.

[0043] The processing steps are the same as in Example 2. After crystallization and filtration, the crystallization raffinate was collected, and the uranium content in the raffinate was measured to be 0.13mg / L, then the raffinate was pumped into the silica gel column by the peristaltic pump again, and the time of the raffinate in the silica gel column was 20min. The residual liquid after passing through the silica gel column is tested for uranium content, and the uranium content is lower than 0.02mg / L, and the secondary crystallization is carried out. The primary and secondary crystals were collected to finally obtain 163.2 g of ammonium nitrate product (purity 99.6%). The second crystallization residue is reduced to 2% of the original volume, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com