A kind of method for recovering copper, aluminum and iron in the leach solution of waste lithium ion battery

A lithium ion battery and leaching solution technology, which is applied in the fields of aluminum and waste lithium ion battery leaching solution to recover copper and iron respectively, can solve the problems of low nickel and cobalt activity, high nickel and cobalt content, low replacement efficiency, etc., and achieve the replacement rate. The effect of fast, high activity and fast filtration rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

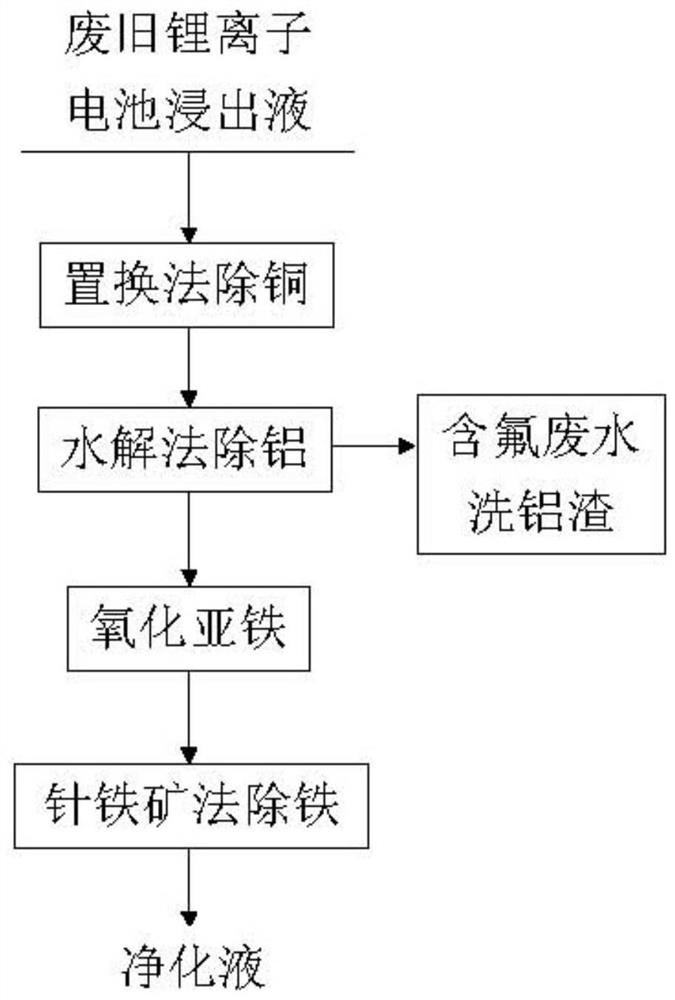

[0061] A method for reclaiming copper, aluminum and iron in the leach solution of waste lithium-ion batteries comprises the following steps:

[0062] (1) Copper removal once

[0063] Take 1L of sulfuric acid leaching solution of waste lithium-ion batteries (main metals: Ni: 46.8g / L, Co: 36.93g / L, Mn: 10.62g / L, impurity Cu: 1.9177g / L), adjust pH=2.8, water bath temperature 60 ℃, add 2g of manganese powder, stir and react for 1h, filter to obtain the first copper removal liquid and sponge copper, detect the Cu in the first copper removal liquid: 0.1567g / L, and the copper content of the obtained sponge copper is 80.46% after rinsing with water.

[0064] (2) Deep copper removal

[0065] Add 1.5g of manganese powder to the primary copper removal solution obtained in step (1), stir at 60°C for 1 hour, filter to obtain the copper removal solution and secondary sponge copper, and detect Cu in the copper removal solution: 0.4mg / L, Optionally, secondary sponge copper is added to the l...

Embodiment 2

[0076] A method for reclaiming copper, aluminum and iron in the leach solution of waste lithium-ion batteries comprises the following steps:

[0077] (1) Copper removal once

[0078] Take 1L of sulfuric acid leaching solution of waste lithium-ion batteries (main metals: Ni: 45.54g / L, Co: 49.44g / L, Mn: 22.57g / L, impurity Cu: 4.2943g / L), adjust pH=3.0, water bath temperature 70 ℃, add 3.7g of manganese powder, stir and react for 1h, filter to obtain the first copper removal solution and sponge copper, detect the Cu in the first copper removal solution: 0.0518g / L, and the copper content of the obtained sponge copper is 84.61% after rinsing with water.

[0079] (2) Deep copper removal

[0080] Add 1g of manganese powder to the liquid after copper removal obtained in step (1), stir at 70°C for 1h, filter to obtain the liquid after copper removal and secondary sponge copper, and detect Cu in the liquid after copper removal: 0.6mg / L, which can be Optionally, the secondary sponge co...

Embodiment 3

[0091] A method for reclaiming copper, aluminum and iron in the leach solution of waste lithium-ion batteries comprises the following steps:

[0092] (1) Copper removal once

[0093] Take 1L of sulfuric acid leaching solution of waste lithium-ion batteries (main metals: Ni: 14.97g / L, Co: 57.69g / L, Mn: 10.28g / L, impurity Cu: 2.8818g / L), adjust pH=2.5, water bath temperature 80 ℃, add 2.4g of manganese powder, stir and react for 1h, filter to obtain the copper-removed liquid and sponge copper, detect Cu in the liquid after copper-removal once: 0.1364g / L, and the copper content of the obtained sponge copper is 82.12% after rinsing with water.

[0094] (2) Deep copper removal

[0095] Add 2g of manganese powder to the liquid after copper removal obtained in step (1), stir at 80°C for 1h, filter to obtain the liquid after copper removal and secondary sponge copper, and detect Cu in the liquid after copper removal: 0.2mg / L, which can be Optionally, the secondary sponge copper is a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com