A treatment process combining sludge drying and gasification

A technology for sludge drying and treatment process, which is applied in dehydration/drying/concentrated sludge treatment, fixed bed gasification, petroleum industry, etc. It can solve the problems of not forming a unified idea and achieve environmental friendliness and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

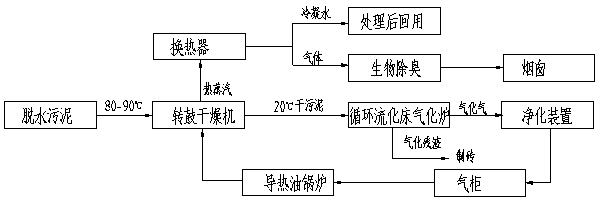

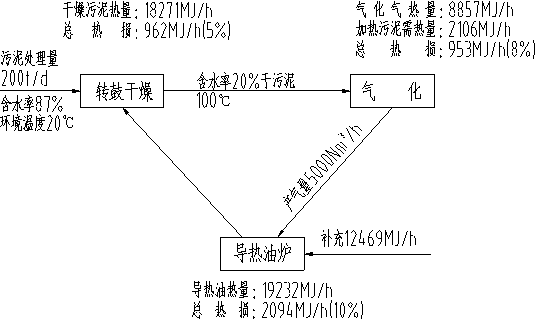

[0018] Refer to attached figure 1 , the combined treatment process of sludge drying and gasification includes the following steps:

[0019] (1) The dewatered sludge with a moisture content of 85-90% from the sewage treatment plant is transported to the plant by tanker, and the sludge is pumped into the sludge receiving bin, and a hydraulic movable carriage is installed at the bottom of the bin to prevent the sludge from being discharged The area is bridged. After the sludge in the warehouse is pressurized by the positive pressure feeder, it is fed to the hydraulic plunger pump, and the odor in the warehouse is collected to the odor treatment system; Dry working environment: fully enclosed, micro negative pressure (500-1000Pa); working temperature range: parts in contact with materials: 180-220°C, exposed parts: 70-120°C; temperature range of hot air: 50-80°C; the heating medium is high-temperature heat transfer oil at 210-240°C. The hot steam evaporated from step (1) is conc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com